The quality of 3D-printed metal parts could soon improve, thanks to new research out of Australia. Scientists there have determined that the application of ultrasound boosts the strength of such items, by modifying their microstructure.

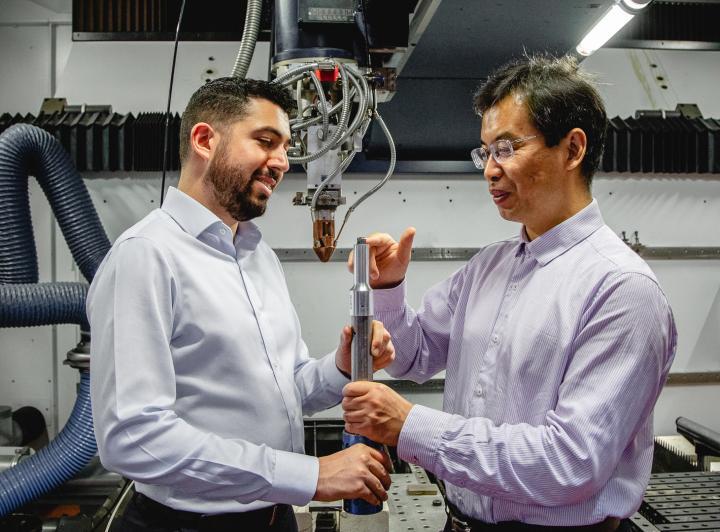

Led by PhD candidate Carmelo Todaro, a team at RMIT University experimented with an existing type of 3D printing known as "directed energy deposition" (DED). In a nutshell, this involves using a laser to melt metal powder as it's being deposited onto a surface, one successive layer at a time. That molten metal subsequently solidifies, forming the finished product.

The RMIT researchers printed sample objects out of two different commonly-utilized alloys: Ti-6Al-4V, which is a titanium alloy frequently used for aircraft parts and biomechanical implants; and Inconel 625, a nickel-based superalloy often used in the marine and petroleum industries.

In both cases, the deposition surface was in fact a sonotrode, which is a tool that produces ultrasonic vibrations. These vibrations were applied as the metal was solidifying, essentially shaking the microscopic crystals that made up its grain, so that they formed into a tighter configuration. As a result, the objects were found to have a 12-percent increase in tensile strength and yield stress, as compared to identical samples that were printed without the ultrasound.

"If you look at the microscopic structure of 3D-printed alloys, they're often made up of large and elongated crystals," says Todaro. "This can make them less acceptable for engineering applications due to their lower mechanical performance and increased tendency to crack during printing. But the microscopic structure of the alloys we applied ultrasound to during printing looked markedly different: the alloy crystals were very fine and fully equiaxed, meaning they had formed equally in all directions throughout the entire printed metal part."

On the other hand, by turning the sonotrode on and off during the printing process, it was also possible to create single items that had different microstructures in different areas. This is a quality known as "functional grading," and it's useful in objects where factors such as low weight or reduced material usage are considerations.

It is believed that once the ultrasound-augmented 3D-printing technology is developed further, it might additionally be used to boost the strength of other metals – these could include stainless steels, along with aluminum and cobalt alloys.

A paper on the research was recently published in the journal Nature Communications.

Source: RMIT via EurekAlert