Installing things like underground water/gas pipes or telecommunications cable conduits can be a very disruptive process. Typically a trench has to be dug first, which is subsequently filled back in once the piping has been laid along the bottom. Might it not be easier if small-diameter tunnels could simply be bored directly into the soil – particularly in urban environments? That's what the autonomous BADGER robot is being designed to do.

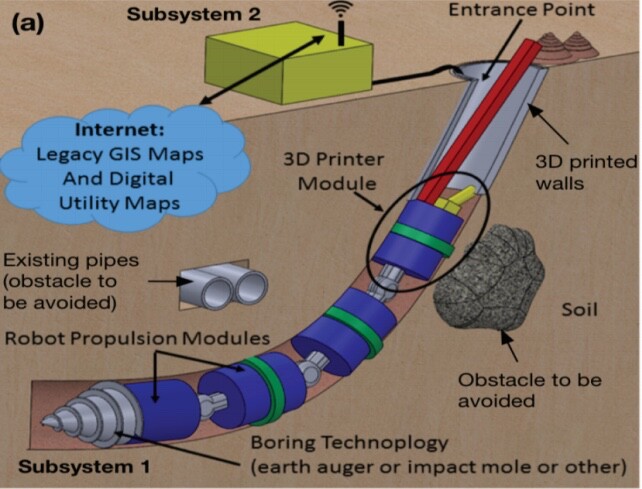

Plans call for BADGER (roBot for Autonomous unDerGround trenchless opERations, mapping and navigation) to have a worm-inspired segmented body, with the segments joined together by universal joints.

At the front will be a drilling head, which will also use ultrasound to help break apart the material that it's auguring into. Each of the segments will be outfitted with mechanisms that clamp against the inside walls of the tunnel. The rest of each segment will then slide forward relative to those mechanisms, allowing the robot to move in much the same manner as a worm uses peristaltic waves to inch its way along.

At the back (or perhaps on another robot following behind) will be a 3D printer. It will deposit a layer of resin on the walls of the tunnel, reinforcing them and essentially turning the tunnel into a pipe.

Power and data cables will run from the back of the robot to a control unit on the surface, where crew members can monitor its progress and even take over and manually control it if necessary. Additionally, a tubular appendage in the rear of the robot will pump dislodged soil up to the surface.

BADGER will also be equipped with an inertial measurement unit – a combination of an accelerometer, gyroscope and magnetometer – that it will use to gauge its relative location within the ground. In this way, it should be able to stay on course. It will be aided by ground-penetrating radar, which it will use to detect and avoid obstacles such as large rocks in its path. That said, its path should be relatively clear, as a surface-located ground-penetrating radar unit will have already been used to initially plot the course of the tunnel.

The three-year project is being led by Spain's Universidad Carlos III de Madrid, and involves researchers from Germany, Greece, Italy and the UK.

Sources: UC3M, BADGER Project