Depending on what they're carrying, tanker truck trailers are often equipped with perforated baffles or solid bulkheads that divide the inside of the tank into multiple compartments. That way, when the truck stops, its liquid load won't all go sloshing forward in one big wave. Dutch engineer Dr. Erik Eenkhoorn believes that's not enough, however … which is why he created the Cairbag system.

According to Eenkhoorn, the problem lies in the fact that while baffles and bulkheads may keep liquids from moving fore and aft excessively, they do nothing to keep them from going side-to-side. As a result, when taking corners, the force of the liquid all moving to one side can be enough to tip the truck over.

"If you are carrying a load of tins of oil, you have to pack the tins in boxes and tie the load down with tarpaulin and ratchet straps," he says. "This prevents the load from shifting during transport. However, there is currently no way to secure a load of, for example, 20,000 litres of oil in a 40,000-litre tank. The result is that the liquid load sloshes around, which causes hazardous situations."

That's where Cairbag comes in.

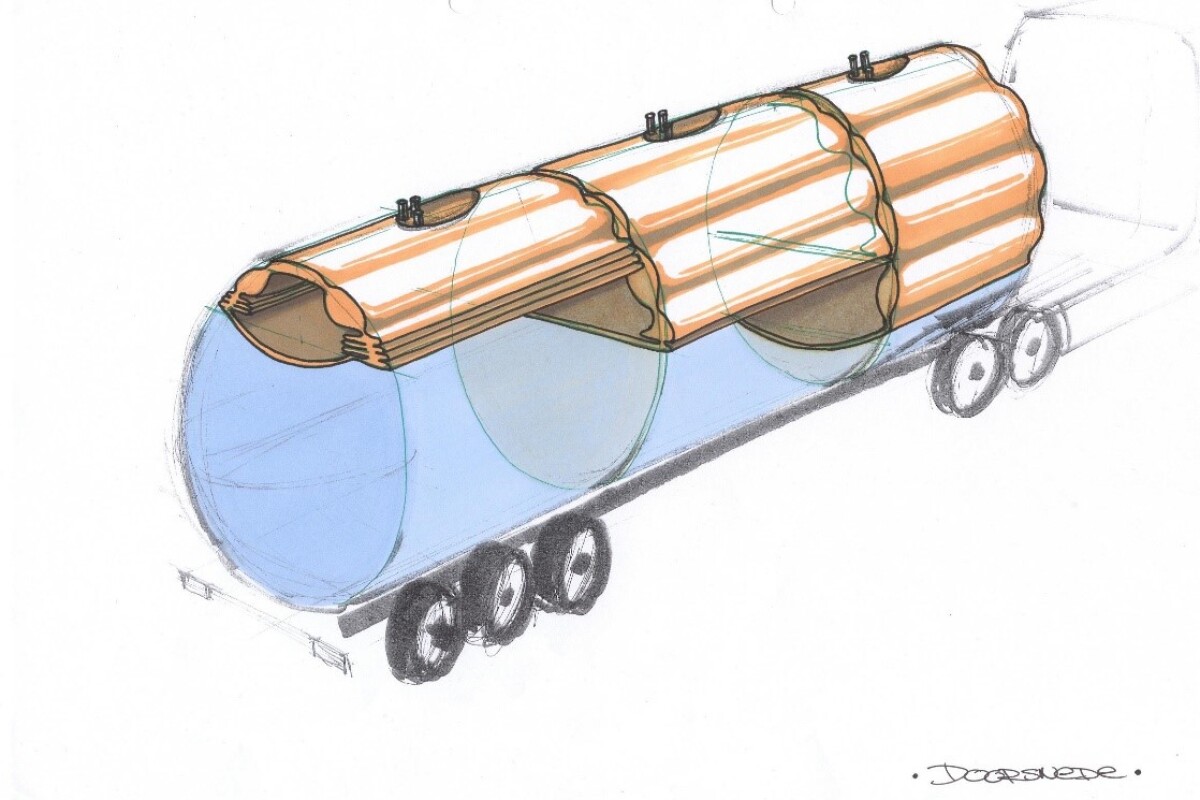

The system consists of airbags that are inflated to fill up all the free space in the tank not taken up by the liquid. This holds the liquid down against the bottom of the tank, keeping it from moving. Not only does that add to safety, but Eenkhoorn states that the improvements in handling should also make the trucks five to six percent more fuel-efficient.

Eenkhoorn's company Accede currently manufactures the Cairbag system.

Source: University of Twente