Keeping electronic devices cool is vital in order to keep them functioning properly, but the components used to contain the heat can add quite a bit of bulk to their overall size. Electrical engineers at Stanford University have developed a promising, atomically-thin alternative based on graphene that offers excellent thermal insulation, despite being 50,000 times thinner than a sheet of paper.

In efforts to prevent things like laptops, smartphones or other gadgets from becoming too hot and malfunctioning or even exploding, engineers might integrate sheets of glass, plastic or even air gaps into the electronics to use as heat shields. But Eric Pop, a professor of electrical engineering at Stanford, has been thinking about controlling this heat in a different way.

Rather than a singular, solid mass of glass, Pop and his team have taken inspiration from double glazed windows and have been exploring the use of alternating ultra-thin materials as a more compact solution to thermal insulation. And recent advances in material science have made this an entirely realistic proposition.

Graphene is a single layer of carbon atoms and since its discovery in 2004 we have seen it open up all kinds of possibilities, driven by the fact that it is atomically thin yet the strongest manmade material at our disposal. Scientists hope to use this wonder material for everything from new forms of magnetism, to lighter and more efficient armored vehicles, to stronger and lighter airplane wings.

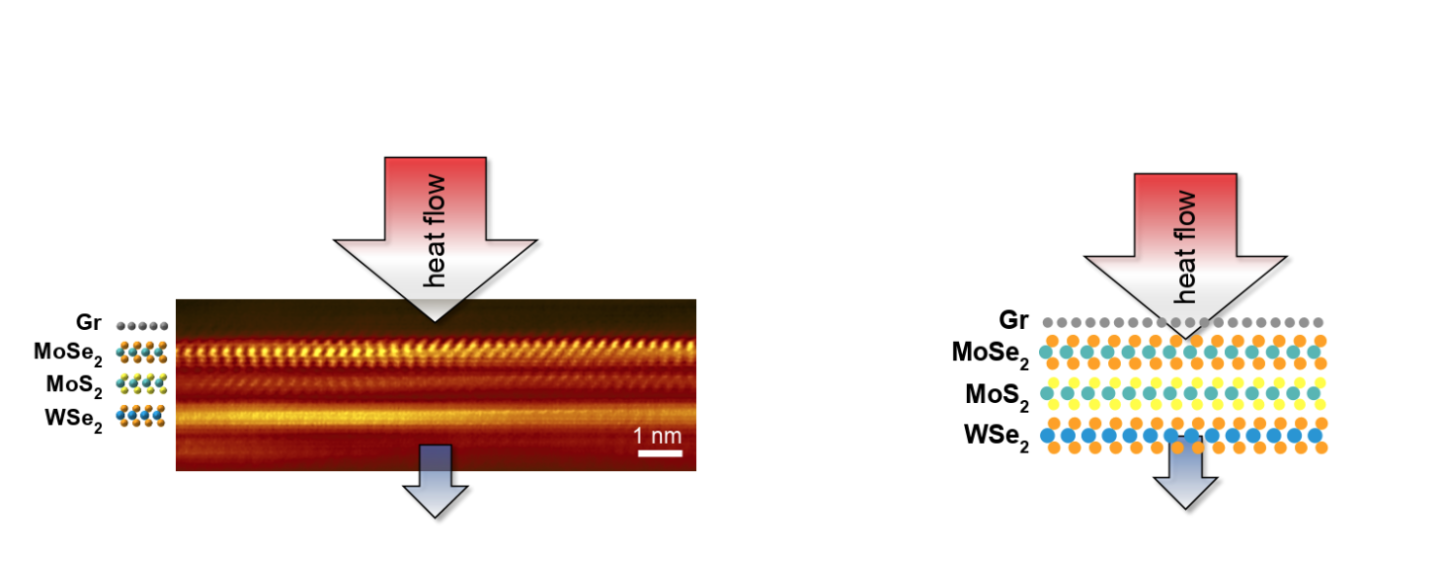

Now ultra-thin heat shields are also part of the equation. Pop and his team combined a layer of single-atom graphene with sheets of other 2D materials (molybdenum disulfide, molybdenum diselenide and tungsten diselenide), each measuring three atoms thick, stacking them on top of one another like sheets of paper. The thermal insulator made up of four layers measures just 10 atoms thick as a whole, and when put to the test, proved rather effective at taking the heat.

“We measured the ability of these atomically thin layers to block heat flow,” Pop explains to New Atlas. “Briefly, we used the graphene layer on top as an ultra-thin electrical heater, and then measured how heat flows through the rest of the layers using a Raman laser. The laser power is low, so it does not introduce extra heating, but the laser returns a signal that is sensitive to the temperature of every material in the stack.”

The scientists say that when placed over a hot spot, the device can provide the same level of insulation as a glass sheet 100 times the thickness. Down the track this could have very useful implications in the pursuit of ever-thinner and more compact electronics, and while reproducing the material on a mass scale will have its challenges, the team sees a few possible pathways forward.

These could include automated large area transfers of the ultra-thin materials, or growing them directly on top of one another. Another option could be to use something like inkjets to spray-coat the layers onto electric components during manufacturing.

"All these methods have already been demonstrated to some degree, and they all have some benefits and some disadvantages," Pop tells us. "For example, spray-coating may be the cheapest method, but may also produce lower-quality films. Direct growth would yield the highest-quality materials, but is probably the trickiest to get right."

In the meantime, the scientists are also eyeing a longer-term and big-picture possibility for this kind of technology. The heat within electronics is actually made of high-frequency, inaudible vibrations caused by collisions between electrons on the move and materials they encounter. By dampening these vibrations as they leave their source, scientists hope to one day manipulate their energy as a way of controlling heat, an emerging field of science known as phononics.

“For example, it would enable us to route heat better in ultra-compact geometries, like in our cell phones and laptops,” Pop explains. “Right now, as I type this, my laptop keyboard is quite hot, but it would be great to route heat perfectly sideways, and exhaust it entirely in the back or sides, rather than having it warm up my fingers, which is getting uncomfortable.”

Pop says there are fundamental reasons that this is either not currently possible or very hard. One of these is the requirement of a new kind of thermal switch for such efficient heat routing, which would enable the flow of heat to be turned on and off. This is a problem he and his team are currently working on.

“The dream here would be to be able to control heat just as easily as we control light and electricity,” says Pop.

The team’s research was published in the journal Science Advances.

Source: Stanford University

Update (Aug. 30, 2019): After receiving feedback from the researchers involved, the headline and parts of this article were altered to clarify some points and lessen the focus on the use of graphene in the team's device.