To develop a new artificial muscle for robots MIT researchers are taking inspiration from an unlikely source – the cucumber. It's not the fruit of the plant that's good for sandwiches and salads that the engineers are interested in, but the tightly coiled tendrils that wrap themselves around solid objects to support the growing plant by corkscrewing and pulling with surprising force.

Artificial muscles aren't new. The need to make robots, prosthetic limbs, and other machines lighter, more responsive, and more efficient has meant that engineers have tried to move away from motors, gears, and pulleys in favor of something more similar to what is found in living organisms.

Toward this end, recent years have seen an explosion of miniature hydraulic systems, shape-memory alloys, servo mechanisms, pneumatics, and polymers. Unfortunately, these have tended to be slower, heavier, and not nearly as strong or responsive as one might wish.

So a team of MIT professors and graduate students decided on a new technique that uses coils of drawn fibers made out of a very stretchable cyclic copolymer elastomer and a much stiffer thermoplastic polyethylene fused into a single strand. These polymers are heat sensitive, but expand and contract at different rates in reaction to heat and cold. The principle is the same found in the bimetallic strips in old-fashioned thermostats, toasters, or the self-correcting pendulums in grandfather clocks. In short, when the strand is heated, one side expands faster than the other and it bends.

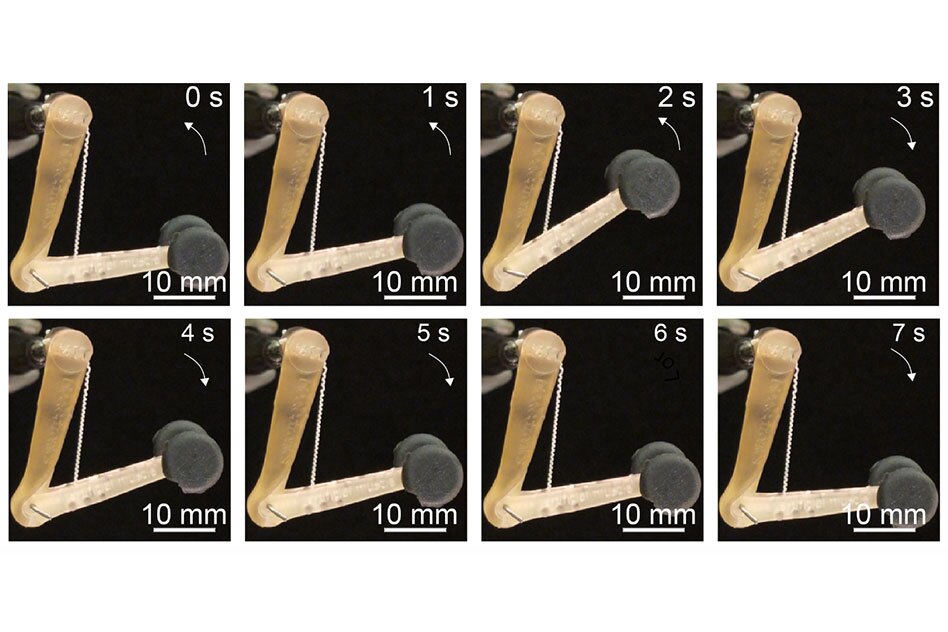

To turn this polymer strand into a muscle, it was stretched to several times its original length. According to the team, this made it curl of its own accord into a very tight coil – rather like cucumber tendrils. In addition, the researchers found that simply holding the strand in the warmth of a hand caused it to coil more tightly with a very strong pulling force. Then, when cooled, it returned to its normal state. And it could do so 10,000 times without losing its properties because it only needed a moderate change in temperature of 1° C (1.8° F) to operate.

The team says that the fibers have a wide variety of types with sizes ranging from micrometers to millimeters in width and lengths of hundreds of meters. One strand is so strong that it can lift 650 times its own weight with the force being controlled by the initial stretch of the strand and how much heat is applied.

For the tests, the fiber-drawing process involved melting the polymers until they became soft, then stretching them out like taffy. During this, the fibers can incorporate other elements, such as meshes of conductive nanowires that were used as sensors during the experiments. The researchers say that such a mesh could also be turned into a heating element to power the muscle internally, as well as feedback sensors to provide more precise control.

The fibers are seen has having a wide variety of applications in robotic arms, legs, manipulators, prosthetic limbs, and tiny biomedical devices. The fibers can also be bundled together to give them greater strength in the same way as organic muscle fibers are bundled.

The research was published in Science.

Source: MIT