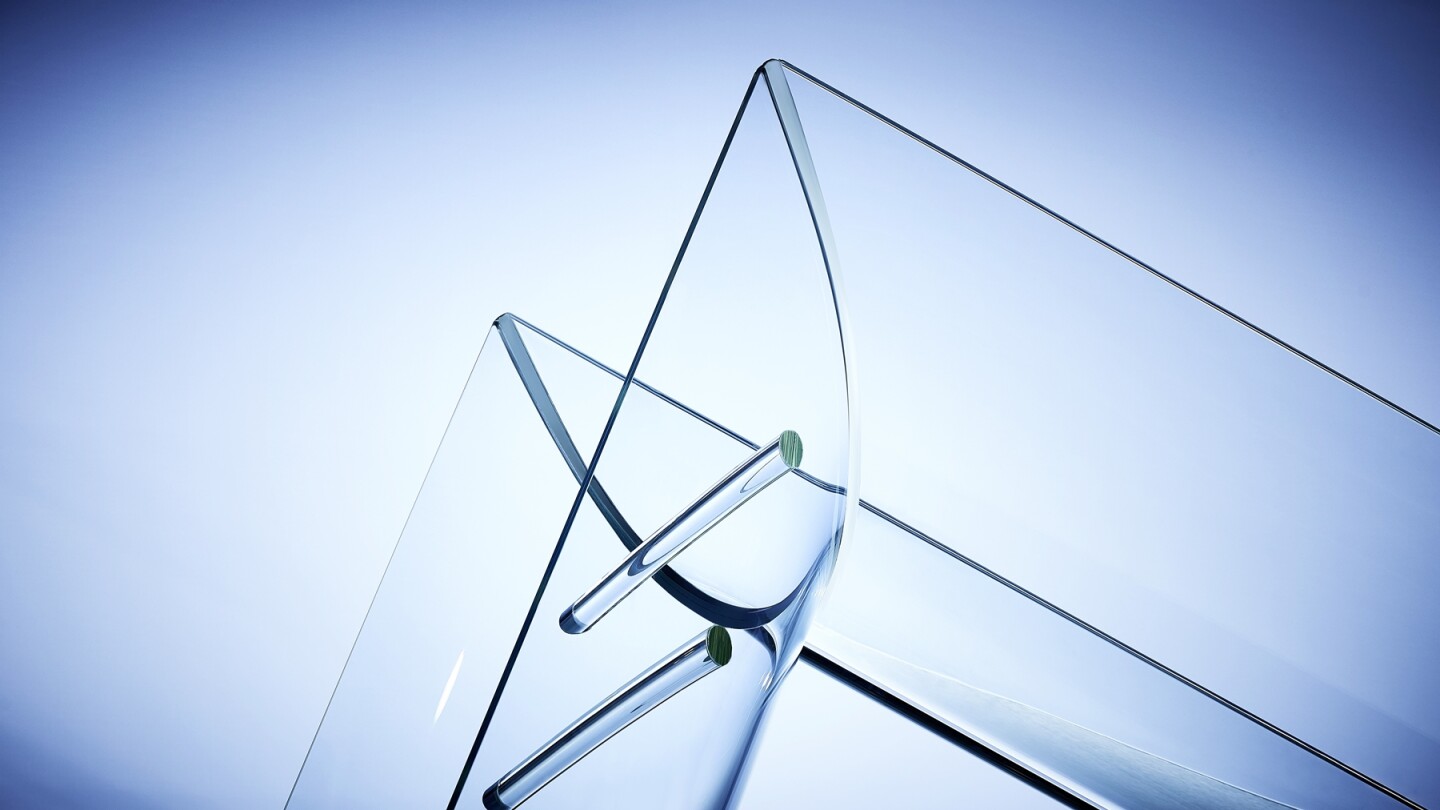

A 9-m (29.5-ft) long fully functional slide is claimed to be the first made entirely out of single pieces of glass. The Vidre-Slide comprises just two half-cylindrical sections bonded together with structural silicone. Not only does it demonstrate cutting-edge glass technology, but the result is a striking work of art.

The 4-m (13-ft) tall Vidre-Slide is the latest in a number of recent glass slides that have been produced, including one installed on the side of the US Bank Tower in Los Angeles. It was created by British engineers Eckersley O'Callaghan in partnership with fabricator Cricursa. The two firms have been working together for some time with the aim of producing long, laterally curved sections of glass with tight radii.

Indeed, it is the tight 450-mm (17.7-in) radii of the sections, coupled with their lengths, that are said to have pushed the boundaries of glass-working. That two such sections are fully formed, rather than constructed from multiple smaller pieces is reported to be rare, if not unprecedented.

The sections are formed by slumping the glass over a curved mold at around 600° C (1,112° F). This isn't so hot as to make the glass molten, but is hot enough to make it malleable. Once it has been shaped, two sheets are then laminated together with an interlayer. In addition to giving the sections a strong load-bearing capacity, the process is able to produce glass that is very clear. It is, however, said to require a great deal of skill.

"There is a lot technology and machinery involved but ultimately the key to achieving quality is through workmanship and experience," Lisa Rammig, Associate at Eckersley O'Callaghan, explains to New Atlas. "For example, the ends of the glass treads are cut at an angle then bonded to a curved surface. Setting out was done all by hand and took real craft to do well."

The slide is designed to carry the weight of a person up to 100 kg (22 lb), although the design is said to ensure that structural integrity can be maintained even if this is exceeded slightly. It is the curved shape of the glass that's reported to give the sections their strength and allows them to be so long, without additional support.

Eckersley O'Callaghan tells us that the curvature of the glass means that sections effectively "want to bend" when they are loaded, making them able to accommodate greater loads than if they were flat. The greater the depth, the greater the bending capacity.

Although the two section of the Vidre-Slide are held in place by a steel base and secured together with structural silicone adhesive, no mechanical fixings are used. The use of structural silicone in this way is another innovative aspect of the slide, with Eckersley O'Callaghan claiming it to be a first. A different transparent adhesive is also used to hold the glass rungs in place on the 4.6-m (15 ft) ladder section of the slide..

The slide debuted at the Glasstec trade fair from September 20 to 23. Eckersley O'Callaghan says it's currently on the look-out for a new venue to host the slide.

Source: Eckersley O'Callaghan