Manufacturing could be dramatically changed thanks to two new techniques for joining materials created by scientists in Austria. The two methods create super strong bonds at the pore level, eliminating the need for caustic adhesives.

While industrial adhesives are great for joining part A to part B, they're not really very good for the environment, especially those made from petroleum-based chemicals. Not only do these adhesives require a good deal of energy and resources to produce, but their manufacture can produce harmful pollutants; plus, once the items in which they've been used reach the end of their lifecycle, they can contaminate soil and groundwater. Additionally, some of the chemicals used in adhesive production can be harmful to the workers using them.

While there has been quite a push to create more eco-friendly adhesives, from such things as a reusable glue made from plants to an adhesive that biodegrades after use, researchers at the Graz University of Technology (TU Graz) in Austria took another approach. Two other approaches, actually, both of which achieved bonds between a variety of wood types and two types of plastics, stainless steel, and a titanium alloy.

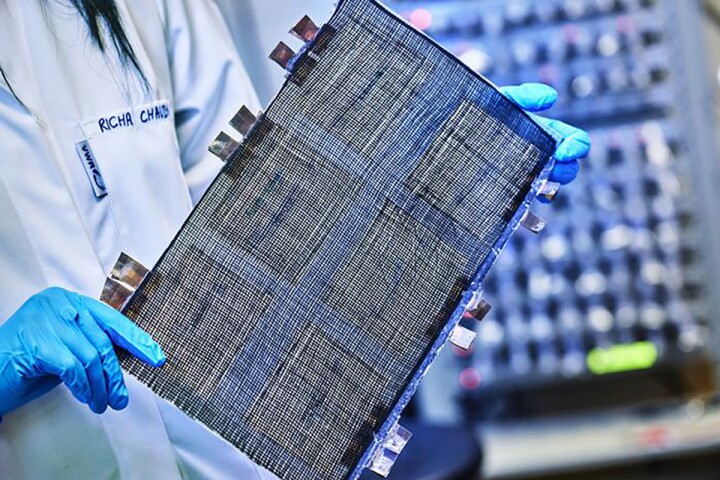

In the first, the researchers used a 3D-printing process they termed "Addjoining." They were able to 3D print the various materials directly onto a piece of untreated wood in such a way that they penetrated the pores in the wood, forming a bond in much the same way an adhesive would. The team then snapped the bond apart.

“After the (bond) fractured, we were able to find polymer in the wood pores and broken wood fibers in the polymer, which suggests that the fracture occurred in the wood and polymer, but not at the joint,” explains Gean Marcatto, who worked on this process as a postdoc at TU Graz's Institute of Materials Sciences, Joining and Forming.

The team believes that the 3D-printed bonds could be made even stronger if the wood was etched using lasers to create more complex structures or larger pores for the other material to bond with.

“But we wanted to work with as few steps as possible and, above all, without chemicals,” says Sergio Amancio, who led the research. “We can use this technology particularly well with complicated 3D geometries because the components are printed directly onto the surface – in whatever geometry is required.”

A sound approach

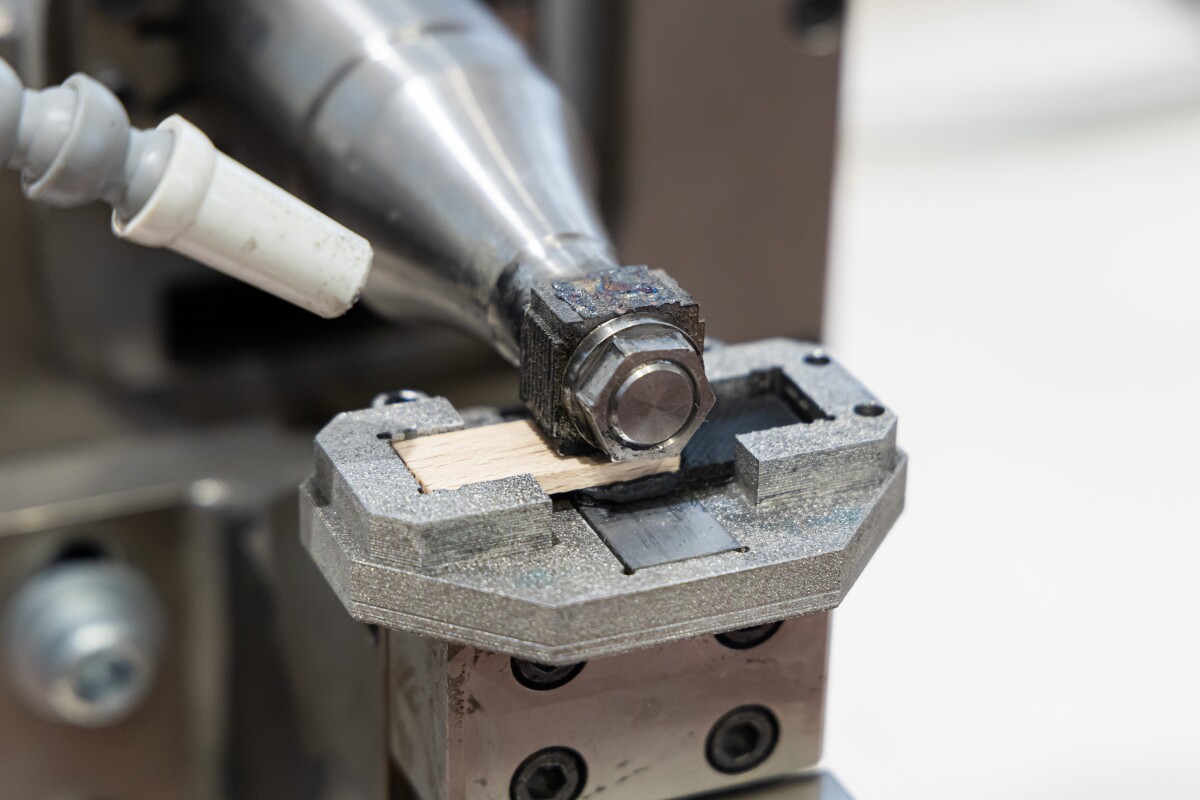

The second joining technique the researchers came up with was called "Ultrasonic Joining." It used an instrument called a sonotrode to send high-frequency, low vibration waves through the juncture of the wood and the metal polymers. This created friction, which generated enough heat to bond the two materials together.

“This technique is particularly suitable for large components and 2D structures since we achieve a precisely localized spot joint,” says Awais Awan, a co-author on the study.

The researchers believes their new green joining techniques can have applications in the furniture, automotive and airline industries.

Their research has been presented at the IIW Annual Assembly and International Conference on Welding and Joining held last month in Rhodes, Greece.

Source: TU Graz