The classic image of a robot is one clad in a rigid metal shell, but that might not be practical in situations where man and machine will need to work together. The emerging field of soft robotics is helping to make that collaboration safer, but recreating muscle is no easy task. Now, mechanical engineers from Columbia University have developed a synthetic soft muscle that's said to be much more simple to make and run than others, and is three times stronger than the real thing.

Most soft robots are powered by pneumatic or hydraulic systems, with their movements controlled by filling and emptying bladders with liquids or gases. The problem is, that usually requires bulky external components like compressors, which prevent the systems from being shrunk down to practical sizes.

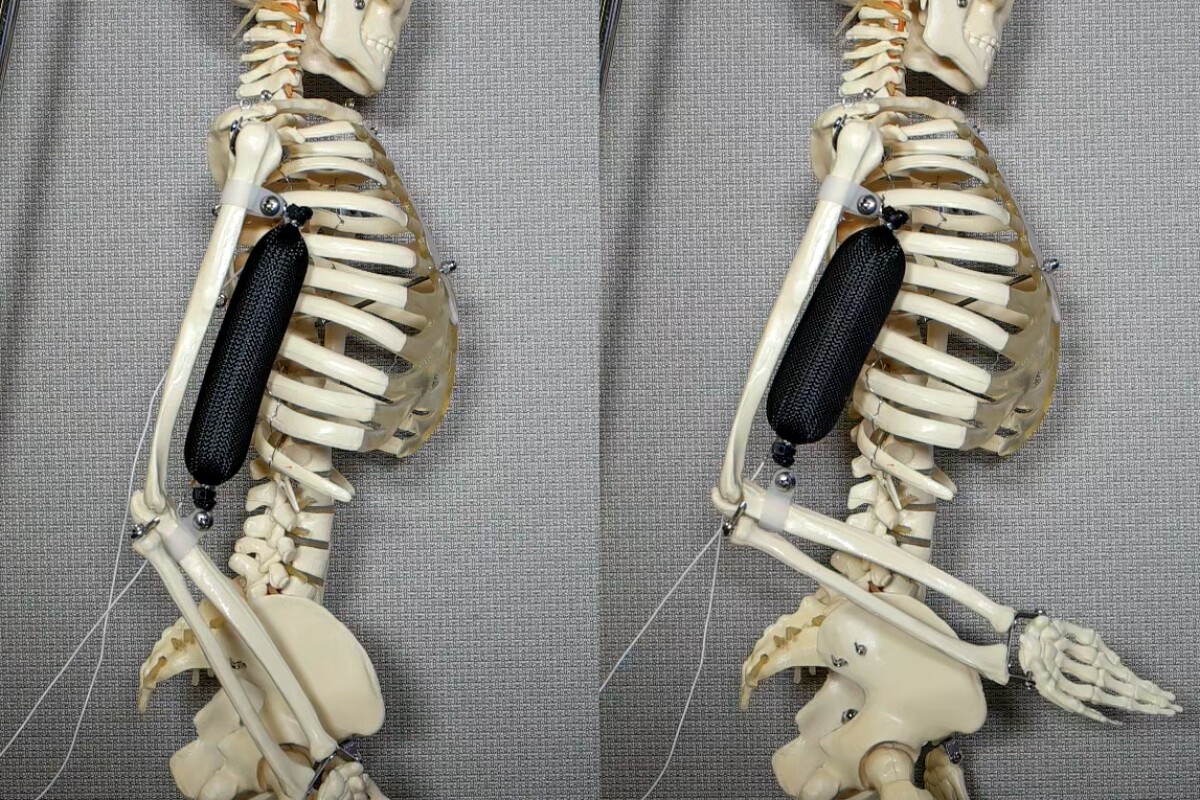

The system developed by the Columbia team is based on a natural muscle. It's made of silicone rubber matrix pocked with micro-bubbles of ethanol, giving the material low density and high elasticity. It can be 3D printed into whatever shape is needed, then electrically actuated thanks to a thin resistive wire embedded inside. Altogether, it can be made easily, cheaply and safely.

"We've been making great strides toward making robots minds, but robot bodies are still primitive," says Hod Lipson, lead researcher on the project. "This is a big piece of the puzzle and, like biology, the new actuator can be shaped and reshaped a thousand ways. We've overcome one of the final barriers to making lifelike robots."

In tests, the artificial muscle was able to expand by up to 900 percent when it was heated to 80º C (176º F) by running 8 volts through the wire. That gives it a strain density (expansion per gram) that's 15 times better than natural muscle, allowing it to lift 1,000 times its own weight.

"Our soft functional material may serve as robust soft muscle, possibly revolutionizing the way that soft robotic solutions are engineered today," says Aslan Miriyev, lead author of the study. "It can push, pull, bend, twist, and lift weight. It's the closest artificial material equivalent we have to a natural muscle."

The next steps for the team include replacing the wires inside the muscle with embedded conductive materials instead, and improving the response time and shelf life of the muscle. Further down the track, the researchers plan to experiment with controlling the system with the help of artificial intelligence.

The research was published in the journal Nature Communications, and the synthetic muscle tests can be seen in the video below.

Source: Columbia University