When you get rid of an old phone or tablet, you're likely to remove your valuable information from it, but what about the valuable materials – like gold – that it contains?

Naturally, such substances are too hard for consumers to retrieve, which might be why, according to the University of Edinburgh (UE), about seven percent of the world's gold supply is currently locked inside of electronics. While removing that gold has heretofore been a highly toxic and inefficient proposition, researchers now think that a new process will make prospecting for gold in electronics heaps more achievable than ever.

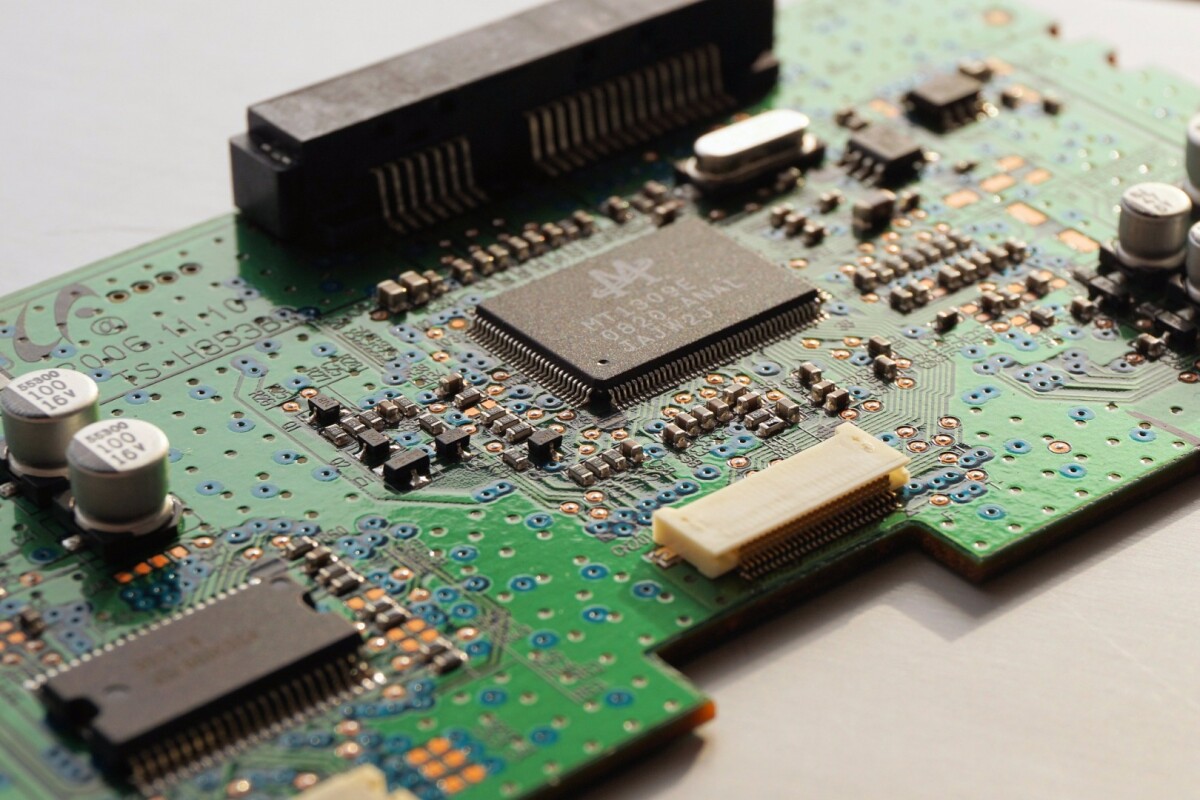

Gold is often found on printed circuit boards, particularly under keyboards where its durability is an advantage. According to the UE researchers, about 300 tonnes of the metal are used in electronics each year.

The new process to remove it uses a mild acid as opposed to harsher chemicals such as cyanide or mercury that are currently used to extract gold.

First, printed circuit boards are dissolved in the acid which turns all of the metal in the board to liquid. Then, an oily solvent made from toluene is added, kicking off a process known as solvent extraction. Toluene is an aromatic hydrocarbon commonly found in paint thinners. The toluene solvent pulls the gold free from the other materials in the acid wash where the metal can be recovered and used again. Likewise, the solvent and acid can be reused, cutting down on waste.

"The solvent extraction technique is great in that the recycling of reagents and acid are integral to the process," lead researcher Jason Love of UE's School of Chemistry told New Atlas.

Love also says that it might be possible to extract other metals using the process.

"Once you have dissolved metals in acid, you can use solvent extraction to separate all of them," he said. "So, in principle, we could devise a process that would be able to separate all of the metals in electronic waste, which of course would have environmental and potentially economic benefits, but this would depend on the prices of metals and the cost of the process."

The work Love and his team carried out is part of a student- and staff-led initiative at UE to promote the circular economy, which focuses on the efficient use of materials and their reuse as well.

Source: University of Edinburgh

![The Ti EDC [everyday carry] Wrench is currently on Kickstarter](https://assets.newatlas.com/dims4/default/0ba225b/2147483647/strip/true/crop/4240x2827+0+3/resize/720x480!/quality/90/?url=http%3A%2F%2Fnewatlas-brightspot.s3.amazonaws.com%2F59%2Fb2%2F6a6fdd0348a8bfdad88bbcefec53%2Fdsc03572.jpeg)