Using biowaste from cassava plants, scientists have created a coating that virtually eliminates friction in metal parts. The breakthrough has the potential to deliver better fuel economy, extend the lifespan of moving parts, and deliver enormous savings in myriad industries.

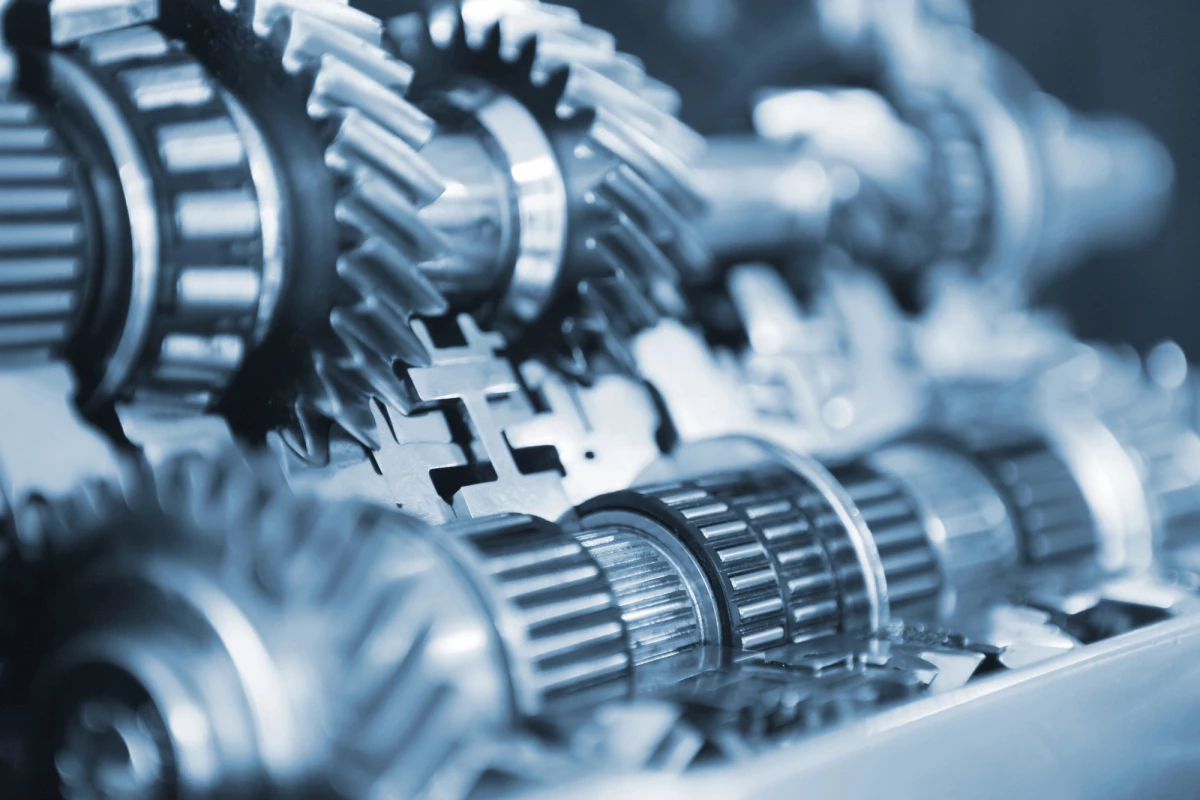

For all they can do for us, moving parts inside machinery come with an inherent problem: friction.

According to a research paper just released by scientists from various institutions in Africa and the United States, friction is responsible for consuming about one-fifth of all energy generated globally each year. Furthermore, the authors write, damage caused by friction in machinery eats up between one to four percent of industrialized economies' GDP. In the automotive industry, the researchers say that about 30% of fuel put into passenger vehicles is used to overcome friction.

Reducing friction, therefore, could have a major impact on the cost of working with machines, and potentially save fuel used in the operation of cars. The research team – led by the president of New York's SUNY Polytechnic Institute, Winston "Wole" Soboyejo, and postdoctoral researcher Tabiri Kwayie Asumadu – decided to take up the friction challenge by focussing on a concept known as "superlubricty." Superlubricity is a condition of near-zero friction between two moving, dry materials in contact with each other.

Until now, superlubricious behavior has only been seen between super-small particles at the nanoscale. The new study though, shows that the phenomenon is possible at the macroscale.

To get it to work, the researchers deposited carbon derived from cassava plants onto metal surfaces using a low-cost high-temperature biowaste treatment process. Once the carbon bonded to the metal, it had the footprint of graphene, a material consisting of a single layer of carbon atoms. This material filled in the grooves caused by wear, creating graphene-only contact points that protected the metal beneath.

In tests, the carbon bonded to steel and nickel substrates led to a virtually frictionless state that remained robust in normal conditions for about 150,000 cycles.

"This research truly could touch most industries," said Asumadu. "From biomedical to energy sectors to nearly every kind of manufacturing, this approach could help to extend the life of machine parts, reduce maintenance and replacement costs, and create a more sustainable industrial future."

The paper describing the findings has been published in the journal, Applied Materials Today.

Source: SUNY Polytechnic Institute