We've chatted with JetPack Aviation's David Mayman many times over the years. His company's groundbreaking work on jetpacks and flying motorcycles seems to proceed at a dizzying pace, and it's always fascinating and enlightening to learn what's new on the workshop bench, so we caught up with Mayman earlier this month to see where things are at.

While the jetpack business continues to progress, with some fun developments in the pipeline, the company's now devoting about 70 percent of its time and energy to its Speeder Air Utility Vehicle. The Speeder will be a totally unique and modular aircraft capable of extremely high speeds, over distances potentially as high as 1,000 miles. It can be configured as a manned flying motorcycle, an unmanned ultra-fast cargo drone, a firefighting platform, or potentially even a manned "Pocket F-35" capable of approaching the speed of sound. It can fly as a jet-powered quadcopter, or clip on detachable wings for high-speed, long-range missions.

Naturally, the US defense agencies are very interested, and the Speeder is one of the top candidates for the US Air Force's AFWERX High-Speed VTOL program. There are also some civilian missions it'd be perfect for, even if its roaring jet engines would be far too loud for inner-city transport.

When we last interviewed Mayman back in July, the team was completing tethered flight tests on the first Speeder prototype, a jet-powered drone called the P1, covered in so much scaffolding it looked like a flying clothes hoist. Since then, it's been replaced by a smaller, but still very industrial looking P1.5 prototype that will soon fly off tether.

Within a few months, we'll see the P2, which will actually start looking like the flying motorcycle that will go to production. This is the prototype that'll eventually begin manned flight tests and high-speed forward flight tests. Like the production aircraft, it'll be highly modular – the JPA team will initially be able to swap from a piloted motorcycle version to a heavy-lift cargo carrier.

And while it'll handle lower speeds and shorter distances straight out of the back of the truck, the Speeder is designed to take a range of different wing options, which can also be easily fitted and swapped in the field. These can unlock speeds over 400 mph (644 km/h), as well as some extraordinary range figures. The team will begin testing a small, low-drag wing configuration with the P2.

If that – and a number of other side projects – wasn't enough to keep the JPA team busy, Mayman's also looking at potentially moving from distributed turbojets to a single-engine turbofan design using cooler, quieter, more efficient ducted thrust – as well as dreaming of a way to get a manned Speeder up close to the speed of sound.

Rather than transcribe our full chat, I've pulled out a series of quotes on each of these topics. The remainder of this piece is thus in Mayman's own (edited) words. I hope you find it as interesting and entertaining as I did!

On the P1.5 prototype Speeder

The P1.5 uses exactly the same control systems, the same jetavators (the thrust-vectoring extensions on the end of the engines that act as control surfaces), as the P1 you saw in July. It's got a way smaller chassis, smaller fuel tank, because the whole thing's lighter. We dropped a lot of that additional scaffolding because we didn't need the side and front tether lines any more; we just went with the one tether line above the aircraft. We've also changed the way we screen the engines for foreign object debris without starving the engines for air.

The guts of the flight control system are the same, but now we're using differential GPS, which means that we have to have a ground station as well as a satellite link. And it just gives us amazing resolution for height and position hold. With the P1, we were within about a meter, now it's down to a couple of centimeters. Rock solid.

I'm sure you can do the same thing with a $500 DJI drone all day long. But to do it with jets instead of electric propellers that can respond instantaneously... We've had to build all the electronics, all the flight control systems from scratch. It's a whole different ball game.

It's absolutely crazy, the amount of energy that we have here in something about the size of a motorcycle, maybe six inches wider. There's no direct way to equate horsepower and thrust, but speaking to our engine manufacturers, the Speeder could potentially produce something like six or seven thousand horsepower. I tell you what, it's very stable in a hover, but when you gimbal those engines even half a degree, it just gets outta there!

So we're continuing tethered tests with the P1.5 out at Moorpark, and we're waiting for our experimental certification paperwork to come back from the FAA, that'll let us get off-tether, and into a much bigger area for test flying. We've got a space marked out in the desert about one and a half hours' drive from LA, pretty convenient from the workshop.

That's about 25 miles by 8 miles, it's quite big, we'll be able to do transition tests. Not with the P1.5 though, we'll start transition tests with the P2. If we happen to have a problem, or a rapid unplanned disassembly, P2 will be way easier to rebuild than the P1.5. It's designed for production; easier to build, easier to maintain. And we'll be building two of those.

I want to keep the P1.5, it's an excellent testbed. One thing we still want to do with P1.5 is to start dynamically moving the dummy load during flight, maybe on a servo or a linear actuator or something. We want to mimic either a piece of cargo moving, or see what happens if the rider tries to mimic riding a motorcycle and leans into a corner. The flight system is amazingly good at counteracting changes in weight, but we haven't tested that in a dynamic way in fight yet.

On the upcoming P2 prototype Speeder

The P2 is a completely different machine. We plan to have it ready for test flying toward the end of March. Again, it'll be smaller. We have some additional hand grips, the tether hold from above goes away. For the flight control system, the hardware is pretty much the same, but the software is completely new.

The jetavators are a new design, so that's going to take some testing. We've completely redesigned the gimbal mounts that tilt the engines backwards and forwards. And just in terms of looks, the whole frame is redesigned. P2 will look way more like a flying motorcycle, if you like, than a testbed. It's going to look pretty much like the production aircraft.

The landing gear has been, without a doubt, the hardest thing to design in this whole project. It's got to be light. It's got to be strong. Ideally it has to be retractable. It has to be the right height – this is going to be used in dual modes, cargo and manned. So if it's going to be manned, somebody needs to be able to get onto it. But it can't sit too low when you're starting the engines.

We're putting a lot of effort into creating an intuitive, motorcycle-type riding experience ...

We've mostly gotten around that in a pretty clever way by gimbaling the engines outward on startup. That blows all of the foreign objects and debris on the ground outward, and sucks clean air in. It reduces the heat buildup under the machine completely. And when you come to takeoff power, it's one integrated effort: the engines spool up and angle back down at the same time.

The whole thing is designed to be modular, for different cargo or manned operations. We have two concepts around pilot positioning. One is leaning forward, as you would be on a motorcycle, in which case you would have a fairing and you would be speed limited to about 200, 250 miles an hour, just based on the massive amount of drag you get – as you do on a motorcycle. The turbulence that you create behind you on a motorcycle is dramatic.

We're putting a lot of effort into creating an intuitive, motorcycle-type riding experience. For example, we're configuring the flight controller so that leaning in results in a nice banked turn, rather than a flat yaw turn.

The other piloted option is recumbent, where you lie down, like in a Formula One style vehicle. It'll have a much higher range and speed, but we haven't done the modeling on that yet. And for cargo, we'll use a very sleek, highly aerodynamic cargo structure. Great lift over drag, very much a teardrop design. That's where we're modeling speeds over 400 miles an hour.

The first piloted position we'll be testing with P2 will be sitting forward like you're on a motorcycle. The idea is that you can take away the pilot piece and put on a cargo bed very easily. The guys that we're talking to at the DOD like the idea of having something that's field-interoperable, where one, or at maximum two people can easily switch the configuration. Because it's fly by wire, you're not introducing any mechanical linkages or control systems, so to go from a cargo configuration to a pilot configuration, it's a matter of taking off the cargo bed, putting that to one side, and then the pilot seat goes on, fairing goes on. The control systems are all just Amphenol; you connect one big fat Amphenol connector and away you go.

We'll be demonstrating the P2 both in a piloted configuration, first unmanned, and then with a pilot on board – yes, I'm still putting my hand up for that – and in a cargo configuration, and we'll be demonstrating a rapid swap between the two.

On the Speeder's detachable multi-profile wing system

The wing we're modeling at the moment is a low-drag, low-lift airfoil designed for high-speed use. It'll probably only start generating meaningful lift at 100 mph or so. It's very small, eight square feet in total, and it'll only add about two feet to the width of the vehicle on each side. We have a carbon spar box that runs through the body of the Speeder, so the wing can clip on and off, there's a carbon box section that slides into the frame.

Having said that, we've also got some potential customers in oil and gas, for example, that might be less concerned with speed than the military, and more interested in going a lot further than we originally modeled. They spend a lot of money running helicopters out to rigs to deliver parts that might only weigh 200 pounds. That two-way trip in a helicopter can cost tens of thousands of dollars, and you're limited by weather in some cases – if the wind's above X, or visibility's down, they just won't run the mission.

Our aircraft is a tiny fraction of the cost of a big twin-engine offshore service helicopter. It can fly in pretty much any conditions, it doesn't care about wind or heavy rain, and it can take 200-pound payloads out to several hundred miles, all day long.

By itself, without wings, we're looking at a range of about 100 miles. With these small, low-drag, high-speed wings, it'll be about 250 miles. And we can build up from there, additional endurance and range is literally just a factor of wing size. We did a trade space study a couple of months ago that suggested we could get out over 1,000 nautical miles in range with larger wings. And again, it'll all be modular and detachable depending on the mission.

One thing I like about the forward, motorcycle-style riding position for us is that it's really easy to extract yourself. You can have a parachute on the pilot, and there's nothing to stop the pilot exiting the vehicle. It's very simple. Once you're in a fully enclosed cockpit, which you'd need to be for extremely high speeds, exiting that is a lot more complex.

On transforming the Speeder into a "Pocket F-35"

I just love the concept of the pocket F-35. My personal mission is to show that we can fly this Speeder, with a person in it, at damn near the speed of sound. One day. It's not going to happen tomorrow. But then you'd have something that can take off vertically from half a car space, do 3, 4, 500 miles at close to the speed of sound and then land again. That's science fiction at the moment, but it's a very realistic engineering dream, and it's certainly a concept that's created a lot of interest here in the US.

We all get into these projects for different reasons. No matter how corporatized the business becomes, the pocket F-35 is still something that individually, as an engineer or an entrepreneur, I'd love to see built.

On a potential move to turbofans

The other thing that's worth mentioning is that we're starting to work with some of the big turbofan producers. I'm really interested in whether we could move to a single engine turbofan instead of using distributed turbojets. Most of the thrust on a turbofan comes from the air that comes through that big fan connected to the gas generator. Could we just duct and vector the thrust from a single, static engine like they did in the Harrier jump jets?

We're heading to our Series A capital raising in the first half of this year. I want to put some of those funds into testing the turbofan concept. The advantages for us would be that the specific fuel consumption is much better, they use significantly less fuel for the huge amount of power they produce. And time between overhauls – the turbojets might get 300-400 hours, depending on the operating environment, turbofans would be more like 6,000 hours.

The other advantage is that they're much quieter and calmer, and the exhaust gases are a lot cooler than the turbojets. It's also a single unit, and that makes it easier to deal with in terms of maintenance and whatnot. And thinking into the future, they're fully certified. If we start looking at moving to a part 23 certified aircraft with the FAA, we'll need a certified engine. We'd need to do that to start flying over cities.

Mind you, our strategy is not around urban air mobility at the moment. There's enough players in the UAM space. When you and I first met, there was probably Joby and a couple of others, now there's what, 300 companies or something trying to get that happening?

A turbofan-powered Speeder would be quieter than the current design, with a cooler exhaust. It'd be a bit larger, maybe a third larger, just to allow for the ducting space and a three foot long, 14-inch diameter engine, which would probably sit in front of you. We haven't got it worked out yet, but that's something we'd like to direct some funds to, along with the ongoing flight testing. There's a lot of work to do there.

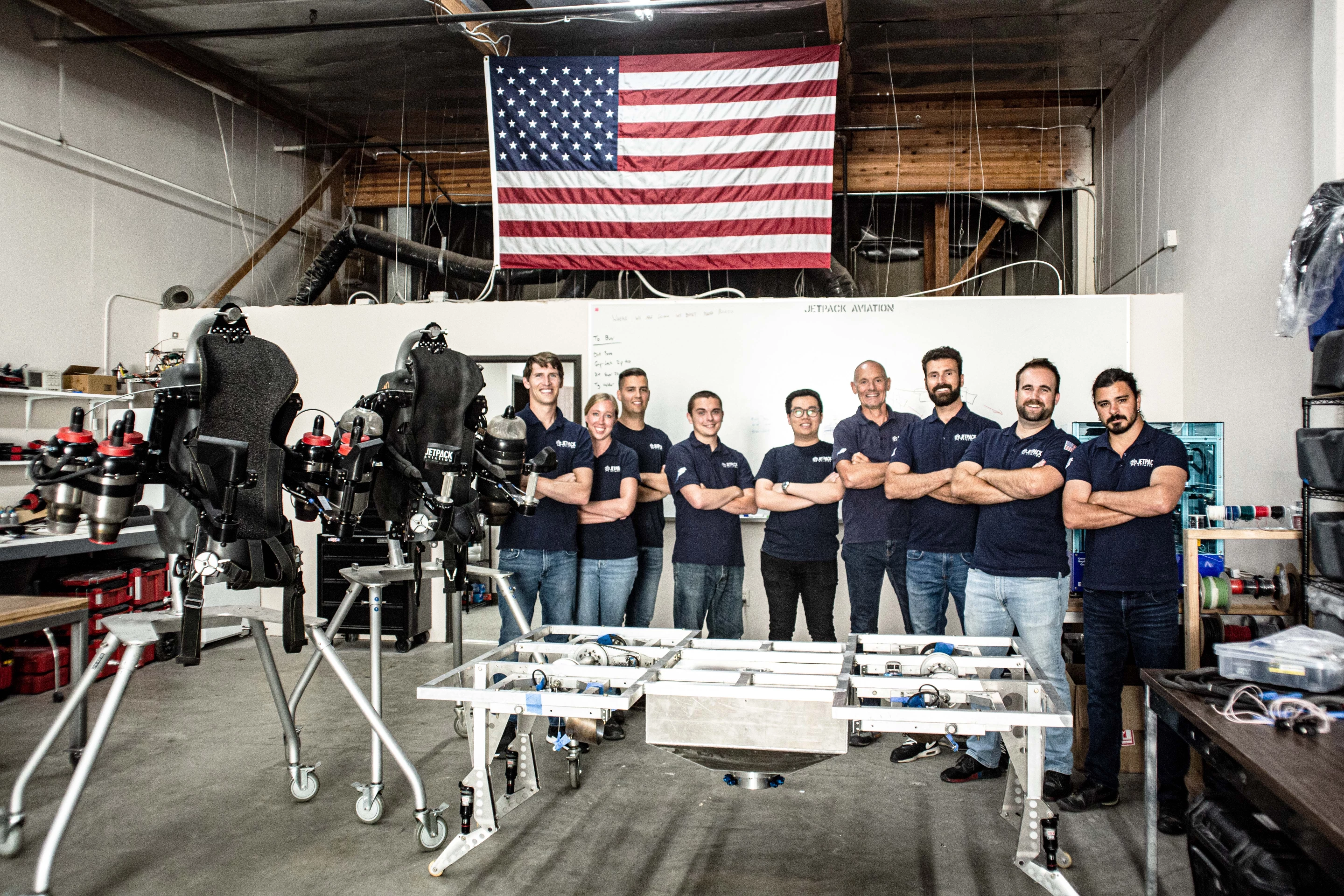

We've increased the size of the team, we're up to 14 now, but to achieve what we want to in the next couple of years, we'll need a bunch more really clever aeronautical and aerospace engineers.

We thank David Mayman for his time, it's always a pleasure to chat. Stay tuned for some other fascinating news from Mayman and the JetPack Aviation team in the coming days and weeks.

Source: JetPack Aviation