Urbee 2, the first road-ready, fuel-efficient car built using 3D printing, is the subject of a collaboration between design firm KOR EcoLogic, direct digital manufacturers RedEye On Demand, and 3D-printing manufacturer Stratsys. Their aim is to put the 7 hp (5 kW) three-wheeled, rear-steering eco-hybrid on the roads by 2015, and then demonstrate its capabilities by crossing the US using only ten gallons (38 L) of fuel.

The first Urbee, introduced in 2010, combined a fuel-efficient 5 hp (3.8 kW) hybrid drive and a 3D-printed body with excellent aerodynamic performance to achieve over 200 mpg on the highway. However, the original 3D-printed body was made using a great deal of excess material to produce strength without the benefit of careful designing. The safety of the car in a crash was also questionable. As a result, the Urbee was a successful concept car, but stopped there.

Stopped, that is, until the Urbee 2 came along. Urbee 2 shares the same general design, being a three-wheeled two-seater that is steered by a single wheel in the rear of the vehicle. It will weigh about 1,200 lbs (550 kg), some thirty percent less than the original Urbee.

The shape of the body underwent subtle changes to optimize its aerodynamic performance, resulting in a drag coefficient of 0.149. For comparison, the drag coefficient of the Toyota Prius and the Tesla Model S, at 0.25 and 0.24, respectively, are among the best of current production cars.

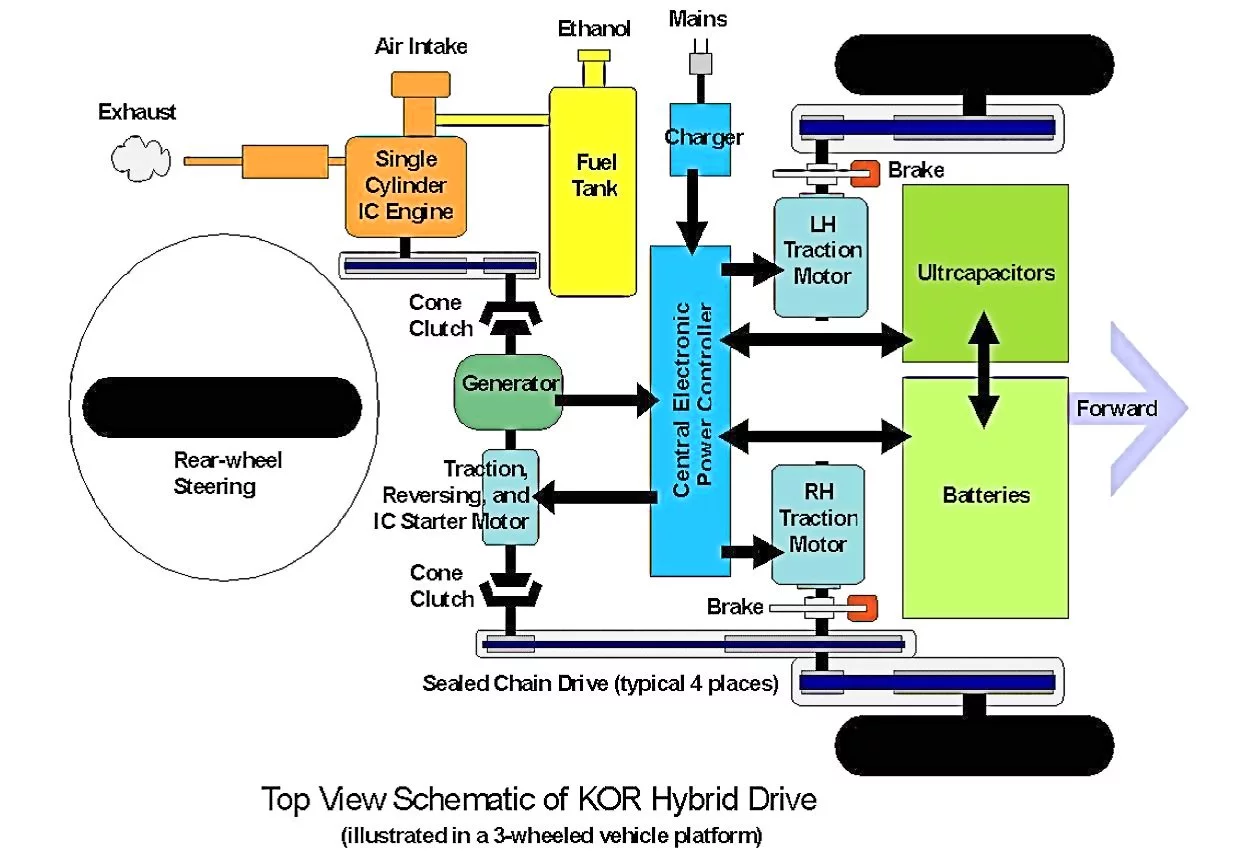

Urbee 2 is a series-parallel hybrid vehicle, meaning it combines more than one energy source to propel the vehicle. In the city, the Urbee runs on electricity stored in its batteries, which are expected to store about 10 hp-hours (7.6 kWh). The front wheels are driven by a pair of 36 volt electric motors, which together provide a cruising power of 8 hp (6 kW) and a peak power of 16 hp (12 kW).

The kinetic energy of the vehicle is largely recovered by a regenerative braking system and stored in a set of ultracapacitors with a capacity of about 0.05 hp-hour (35 W-hr). The pure electric driving range is likely to be in the neighborhood of 40 miles (64 km). Should the batteries start to die during the commute home, an internal combustion engine will run an alternator to charge them.

At highway speeds, Urbee utilizes an internal combustion engine, as such an engine is most efficient when running at about 60 percent of its peak power. This powertrain will allow the Urbee 2 to cruise comfortably at about 70 mph (110 km/h). Although an engine has not yet been selected, it is likely to be a 7-8 hp single-cylinder diesel which can also be run on ethanol. Roughly speaking, this is a very efficient lawnmower engine. When passing or on uphill stretches, additional power is obtained by operating the electric and diesel engines in parallel.

The body and interior are now 3D printed on a set of Stratsys Fortus 900mc 3D production systems. The 900mc systems have a build volume of 36 x 24 x 36 inches (914 x 610 x 914 mm), and an accuracy of better than 0.004 in (0.1 mm).

The Urbee 2 design includes more than 50 3D printed components, which require 2,500 hours of work by the Fortus 900mc systems. "With Urbee 2, more than 50 percent of the car will be 3D printed," says Jim Kor, owner and chief designer of Kor EcoLogic. "Everything you typically see and touch on the car, as you drive the car, will be 3D printed." Interestingly, if you lease the manufacturing time, it adds up to about US$25,000 of the perhaps optimistic estimated $50,000 or less list price.

Many of the printed components are now designed with three-dimensional structures intended to provide more strength and rigidity while requiring lass material. Kor likes to compare the fender of a future Urbee with a bird bone. "If you look at a cross section of a bird bone, you'll see that there is bone only where the bird needs strength," he said. "The bone looks like chaotic webbing. FDM (Fused Deposition Modeling) is the only process that can replicate a bird bone."

These design changes have resulted in the remarkable 500 lb (230 kg) loss of weight. Most, if not all of the 3D-printed components are made of ABS plastic, but the 900mc can also print polycarbonate and polycarbonate/ABS copolymers, which may be used in components requiring greater strength, toughness, or longevity.

To address the safety concerns, the chassis and framing will consist of welded chrome-moly steel tubing. The goal of the design team is to manufacture the Urbee 2 to pass the Le Mans technical regulations, including a NASCAR-style roll cage. The result will be a vehicle that meets or exceeds safety standards. In most places, the Urbee 2 is likely to be registered as a motorcycle, as its size and weight does not fit most definitions of a car.

The most difficult hurdle at the moment is the estimated $3 million that must be raised to fund development of the Urbee 2. Kor is taking advantage of Kickstarter and other forms of crowdfunding, but it seems unlikely that the new prototype will emerge without finding an angel or two along the way. Any volunteers?

The team's Kickstarter video pitch can be viewed below.

Source: Kor Ecologic