Hamburgers are a multi-billion dollar business, and while fast food chains have got the process down to an efficient production line process, making them is still labor intensive with armies of burger flippers and sandwich assemblers. In a move that could put millions of teenagers around the world out of their first job, Momentum Machines is creating a hamburger-making machine that churns out made-to-order burgers at industrial speeds and aims to use it in its own chain of restaurants.

According to Momentum Machines, making burgers costs US$9 billion a year in wages in the United States alone. The company points out that a machine that could make burgers with minimum human intervention would not only provide huge savings in labor costs, but would also reduce preparation space with a burger kitchen replaced by a much smaller and cheaper stainless-steel box.

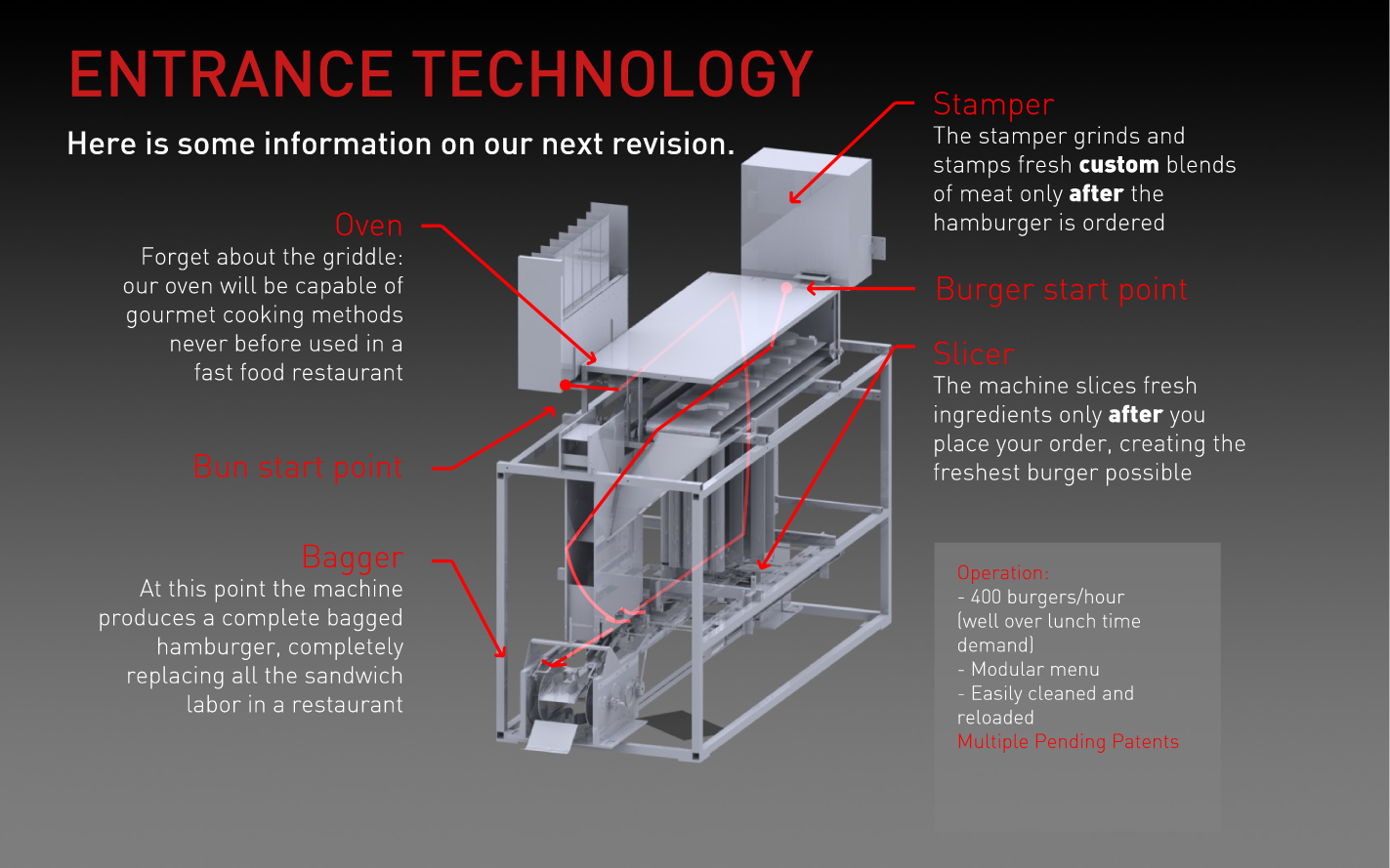

This self-contained, automatic device sees raw ingredients go in one end and the completed custom-made burgers come out the other at the rate of up to 400 per hour. The machine stamps out the patties, uses what the company says are "gourmet cooking techniques never before used in a fast food restaurant,” applies the toppings (which are cut only after ordering to ensure freshness), and even bags the burgers.

The company plans to open its first restaurant in the near future and to market the machines to third parties, arguing that one can pay pay for itself inside of a year. The company is targeting restaurants, convenience stores, food trucks and vending machine applications. In the meantime, the device is still undergoing development with a feature to allow for custom-ground and mixed beef to be included in the next generation.

Source: Momentum Machines via Foodbeast