Today’s bridge columns are typically formed by large monolithic concrete structures that afford them great strength, but do invite the possibility of cracking should an earthquake strike. There are other options, including constructing these load-bearing structures out of limb-inspired joints and sections, which a new study suggests could not only offer greater durability under seismic activity, but also be repaired on the cheap should cracks start to appear.

The novel bridge design examined in this research is known as a hybrid sliding-rocking bridge, which engineers at Texas A&M University have been investigating as a more earthquake-resistant alternative to conventional designs.

These columns offer the same support as typical concrete bridge columns but are able to absorb more energy from ground-shaking thanks to moving joints and segments inspired by human limbs. If an earthquake hits, the individual segments slide over one another instead of cracking, at least that’s the idea. But there is a lot to learn about how this would play out in the real world.

“Our bridge design is relatively new and so there is little scientific literature that we could refer to,” says study author Dr. Petros Sideris. “And so, we took an unconventional approach to fill our gap in knowledge by recruiting a panel of experts in bridge damage and repair.”

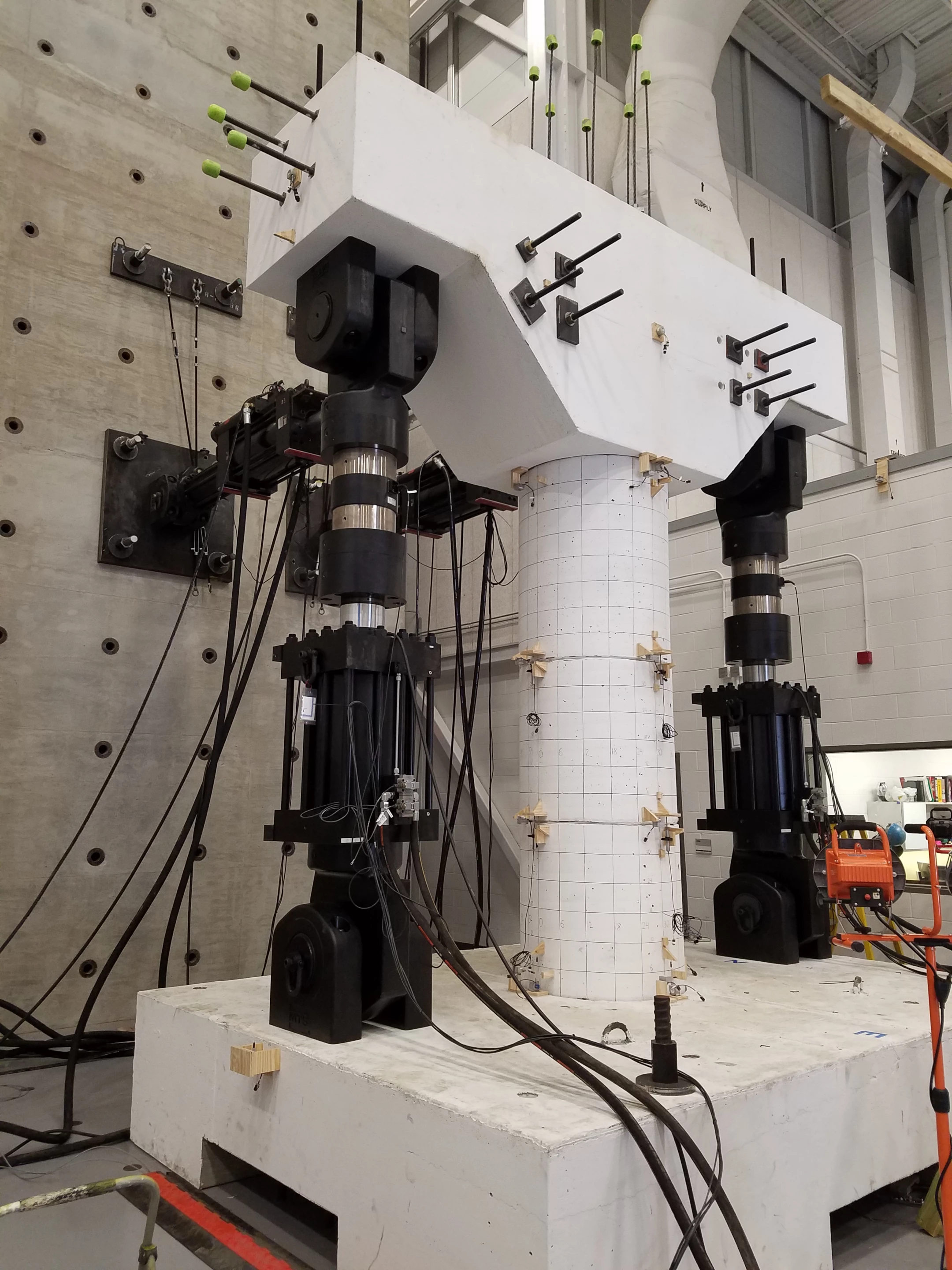

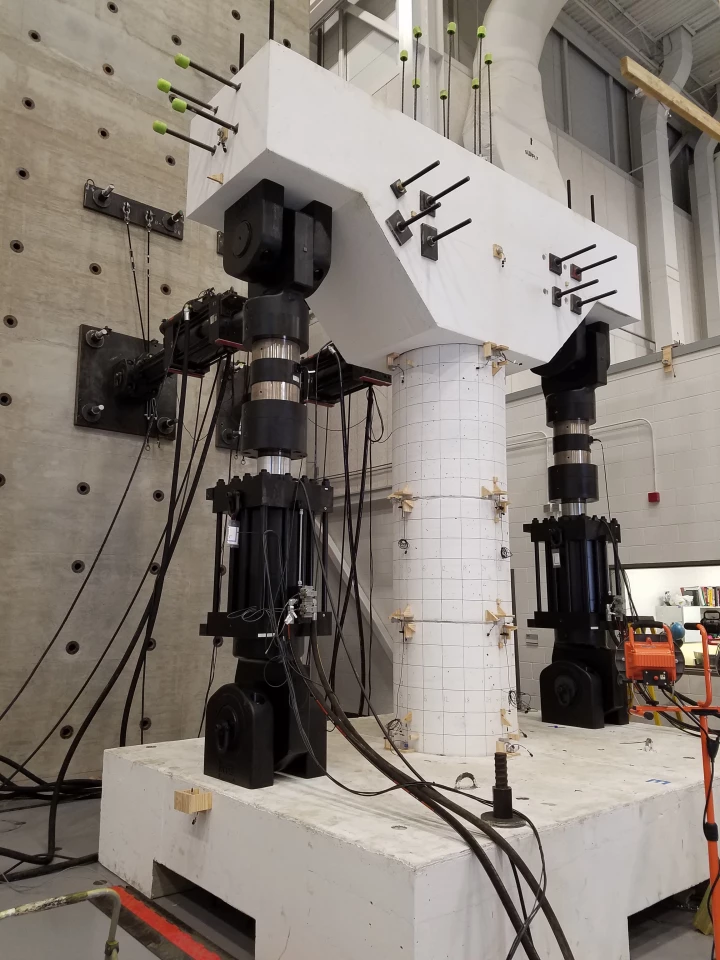

This team of experts ran a series of experiments in which hybrid sliding-rocking columns were subjected to motion that simulated seismic activity. This allowed them to observe the damage taking place and come up with techniques and cost estimates to repair it. Using this information they then repaired the columns before subjecting them to more of the same simulated seismic activity that had damaged them in the first place.

These repeated experiments enabled the team to compare the performance of the repaired columns to columns in their original state, along with columns built in the conventional way. The engineers found that the hybrid sliding-rocking columns experienced less damage than the conventional designs and very little damage overall, even when subjected to forces equivalent to once-in-a-few-thousand-years earthquakes. When they did become damaged, the engineers found they could be easily patched up with grout and carbon fibers.

“Fixing bridges is a slow process and costs a significant amount of money, which then indirectly affects the community,” says Sideris. “Novel bridge designs that may have a bigger initial cost for construction can be more beneficial in the long run because they are sturdier. The money saved can then be used for helping the community rather than repairing infrastructure.”

The research was published in the Journal of Structural Engineering, and Dr. Petros Sideris provides an overview of hybrid sliding-rocking bridges in the video below.

Source: Texas A&M University