While the field of stretchable electronics does hold a lot of promise, joining the components of such devices together can be tricky. A new connector is designed to help, as it stretches between the components, plus it links them to one another in a matter of seconds.

As things currently stand, the various parts of stretchable electronic devices (such as soft-bodied robots or wearable sensors) are often glued directly together. Unfortunately, electrical signals can't travel through the glue. Additionally, the glue's bond will soon break when those pieces are pulled in opposite directions.

Seeking a better-functioning alternative, an international team of scientists led by Prof. Chen Xiaodong from Singapore's Nanyang Technological University created a ribbon-like connector called the BIND (BIphasic, Nano-dispersed Interface).

It's composed mainly of a soft thermoplastic that's already widely used in stretchable electronics, known as styrene-ethylene-butylene-styrene. Embedded within the thermoplastic matrix are electrically conductive nanoparticles of gold or silver.

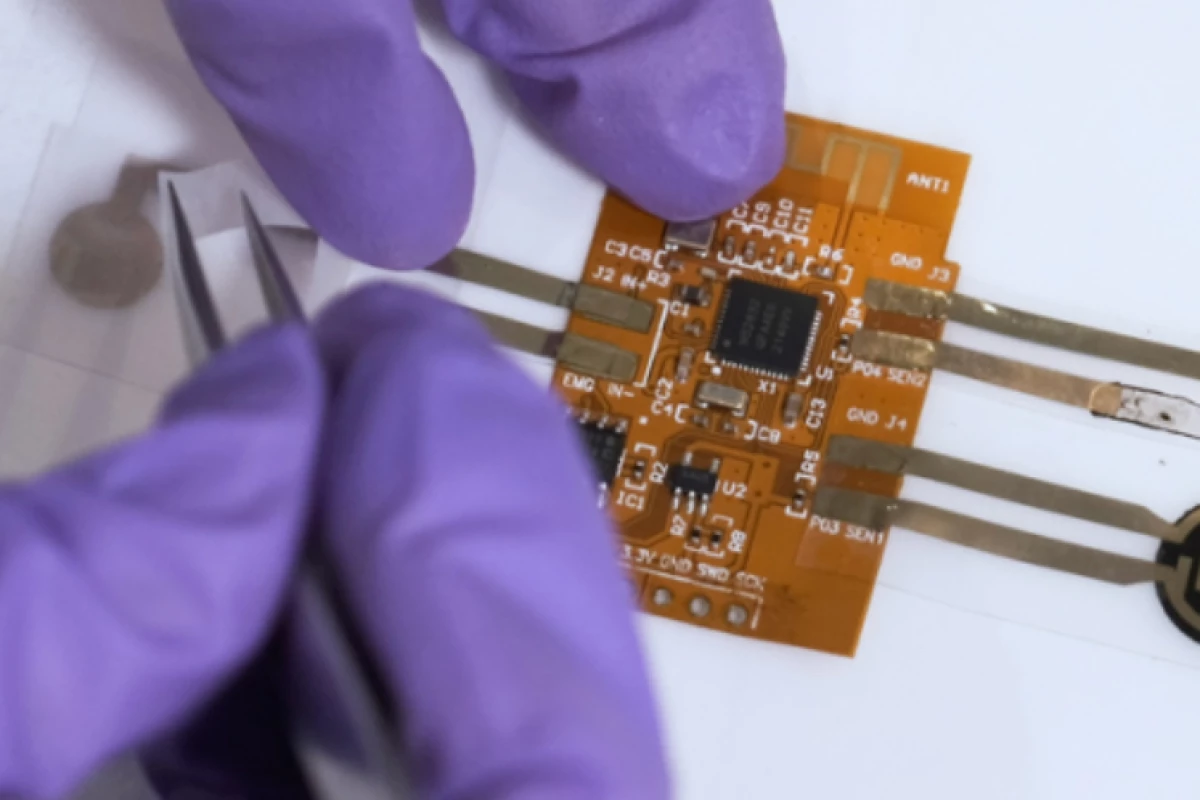

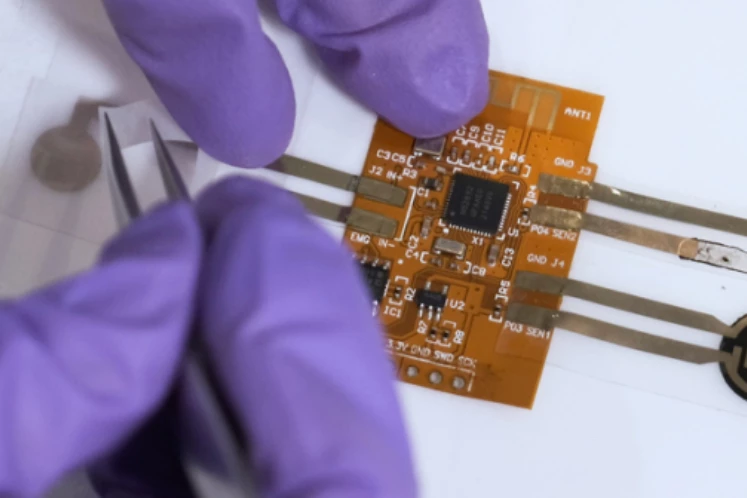

When users are assembling stretchable electronic devices, they simply press each end of one BIND connector to the circuitboard, etc in each of two components – the ends securely adhere themselves to those items in just 10 seconds. The connector can then be stretched up to seven times its relaxed length without breaking. It also continues to carry a robust electrical signal between the components while being stretched by up to 2.8 times its normal state.

Additionally, a standard Peel Adhesion Test showed that the two ends of the connector (which are bonded to the linked components) have 60 times the adhesion toughness of traditional connective glues.

The technology has already been successfully tested on monitoring devices which were attached to rats and human skin, in the latter case measuring the electrical activity of arm muscles even when underwater.

"These impressive results prove that our interface can be used to build highly functional and reliable wearable devices or soft robots," said Nanyang's Dr. Jiang Ying. "For example, it can be used in high-quality wearable fitness trackers where users can stretch, gesture, and move in whichever way they are most comfortable with, without impacting the device’s ability to capture and monitor their physiological signals."

A paper on the research – which also involved scientists from Stanford University; Shenzhen Institute of Advanced Technology; Agency for Science, Technology and Research (A*STAR); and the National University of Singapore – was recently published in the journal Nature.

Source: Nanyang Technological University