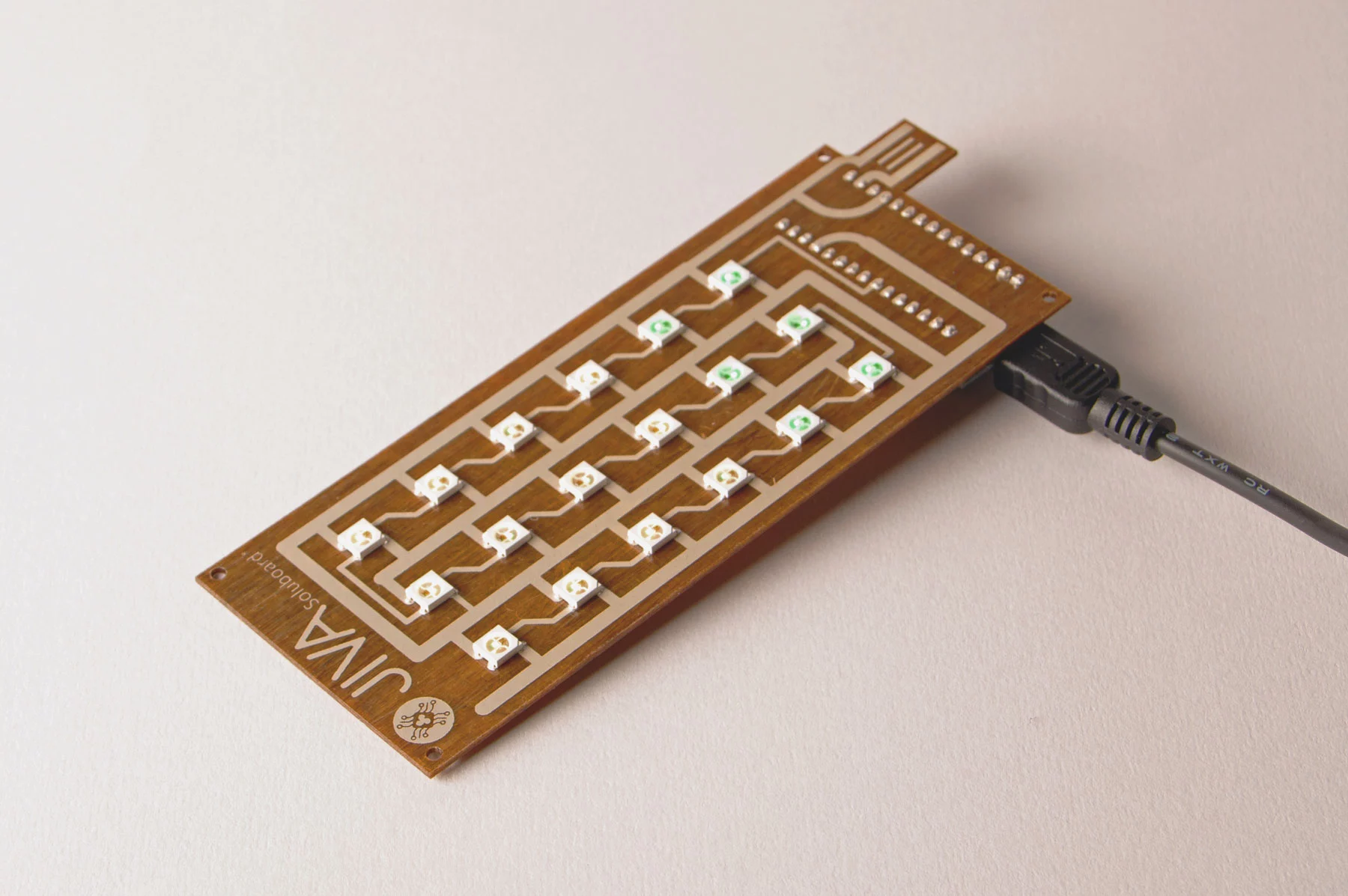

Our appetite for new gadgets is resulting in a huge e-waste problem, with just a fraction of the 50 million tonnes of tech thrown away each year being recycled. Looking to tackle a significant part of the problem, the UK's Jiva Materials has developed a PCB substrate that breaks down in water for easier recovery of materials. The startup is now partnering with European manufacturers to demo and evaluate the Soluboards.

Jiva says that some 18 billion square meters of printed circuit boards (PCB) are produced each year, but recovering valuable materials from a spent board can be a complex, costly and energy intensive process where the epoxy resin and fiberglass boards are shredded and incinerated to reclaim the metals.

The Soluboard is made from plant-based fibers, a non-toxic polymer and a halogen-free flame retardant. When immersed in hot water, the polymer dissolves, which breaks apart the natural fibers for composting while allowing 90% of the electronic components to be recovered for reuse or recycling. The remaining water/polymer solution can then "be disposed of using standard domestic waste water systems."

Jiva's board is reported to have an estimated carbon footprint of 7.1 kg per square meter produced, whereas fiberglass-based boards (FR-4) come in at 17.7 kg, with the company also pointing to a significant saving in plastic of 620 g per sq m.

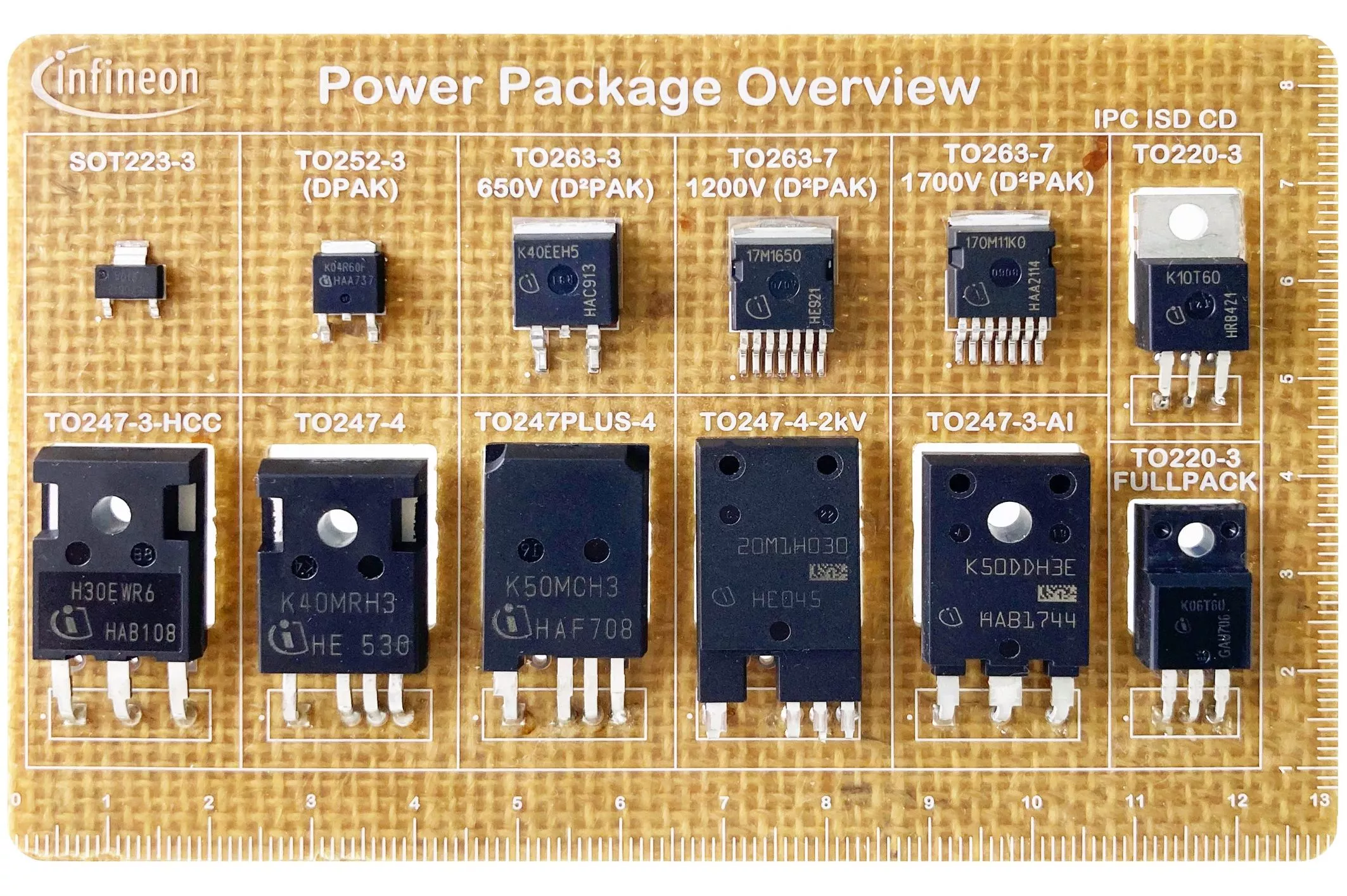

Germany's Infineon is among the first to research the use of Soluboard for demonstration and evaluation boards. Three different demo boards have so far been produced, with more than 500 units already in use across its power discretes range (including one specifically designed for refrigeration applications).

Stress testing is currently underway, but the hope is to develop more boards over the next few years ahead of possibly "using the material for all boards to make the electronics industry more sustainable." The company will use the lessons learned from the project to help customers incorporate the new material in core applications, while providing guidance on the reuse and recycling of components recovered from Soluboards.