What snowboarder wouldn't like a board that's lighter and more responsive? German scientists have created one that is claimed to deliver on both counts, plus its production process is reportedly less wasteful.

Ordinarily, lightweight composite snowboards are made from layered sheets of interwoven carbon or glass fibers, to which resin is added. Those sheets are cut from a roll of material, then trimmed to the exact size and shape required. This means that scraps of the material end up being left over, and are typically just discarded – even though the manufacturer paid for the whole roll.

Additionally, each sheet of the material is of a uniform consistency all the way across. While this is desirable in some situations, it does present a challenge when trying to tweak the characteristics of the finished composite. Manufacturers may wish to make the board more flexible in some areas and stiffer in others, for instance.

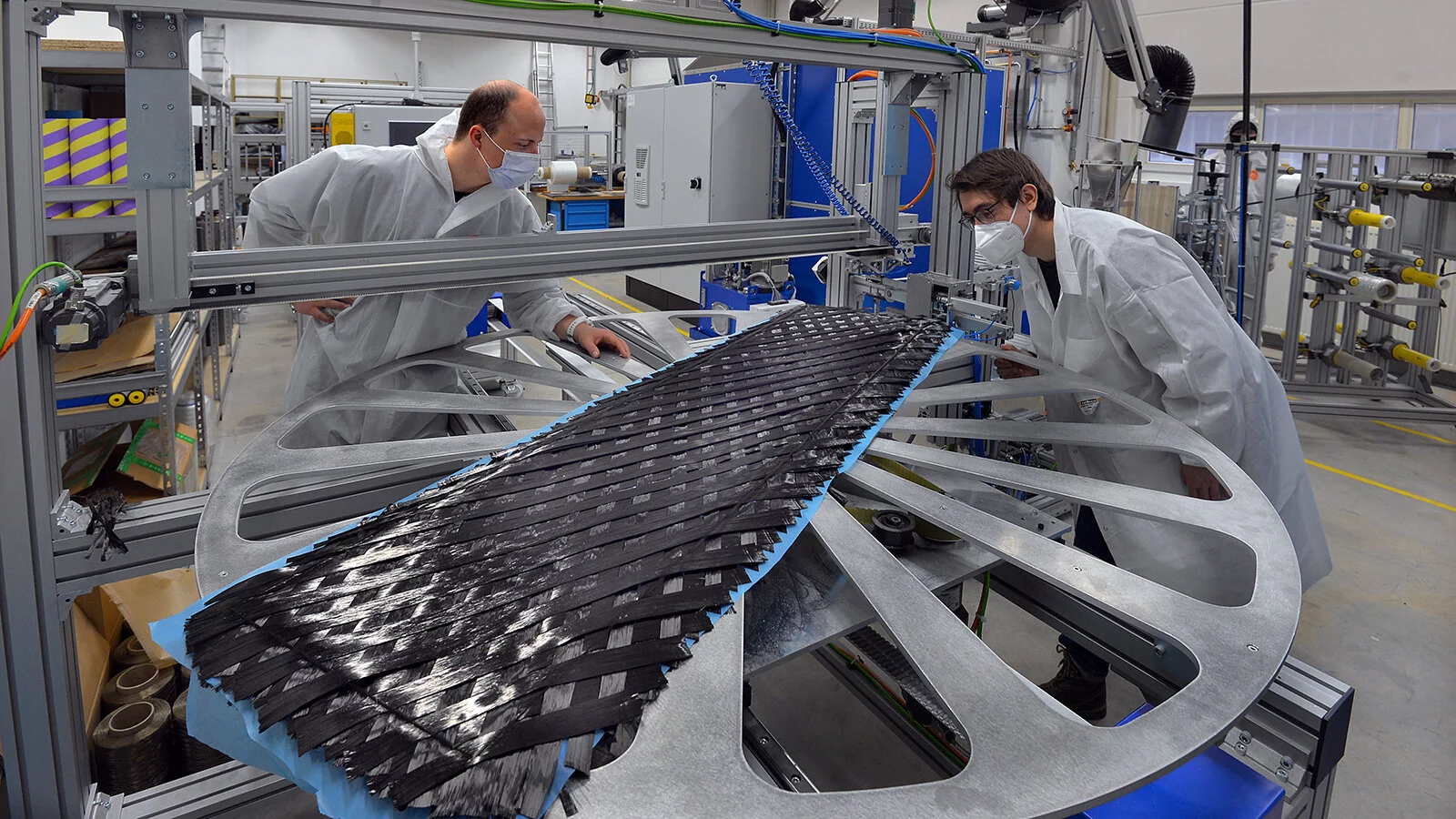

With these limitations in mind, a team from the Chemnitz University of Technology has built a prototype snowboard via a variation on an automated technique known as dry fiber placement. This involves pulling individual carbon and glass fibers off of a spool, and laying them directly into the snowboard form, around a wooden core. Resin is added when layers of these fibers are subsequently laminated together.

In this way, all of the fiber that's allocated to one snowboard goes into that board – there is essentially no waste. Additionally, the qualities of different parts of the board can be adjusted by controlling the manner in which the fibers are deposited. For example, they can be tightly packed in some places and more widely spaced in others.

The 1.6-meter (5.2-ft) Chemnitz prototype is actually a splitboard, meaning it can be horizontally split into a pair of touring skis for getting up the mountain, then joined back together into one snowboard for going down. Tipping the scales at 2.6 kg (5.7 lb), it is said to be one of the lightest splitboards in the industry.

Additionally, its uniquely deformable edges are claimed to increase hold by digging into the snow when cornering, while also lifting up to avoid catching during a maneuver known as a boardslide. All told, the scientists estimate that manufacturing snowboards in such a fashion could reduce fiber waste by about 60 percent.

"This not only saves costs, but thanks to the board’s sustainable production, its carbon footprint is also significantly reduced," says Prof. Holger Cebulla, who is leading the research along with Dr. Joerg Kaufmann.