The US Air Force is installing a nuclear micro-reactor at Eielson Air Force Base (AFB), located 26 miles (42 km) southeast of Fairbanks, Alaska. Authorized by the Department of the Air Force, the commercially-owned next-generation reactor is scheduled to go into operation by 2027.

The US military operates bases and other installations located in remote, inaccessible regions – not only abroad, but also within US states and territories. Supplying these sites is often a formidable task, especially when it comes to heating and electricity.

In the case of Eielson AFB, this means regularly hauling in tonnes of coal to provide it with 33.5 MW of electricity. Aside from the environmental impact, it's also expensive, a logistical nightmare, and ties up personnel better employed elsewhere. This isn't unique to the Alaskan base, so the Air Force is interested in looking at nuclear energy as a cleaner and simpler alternative.

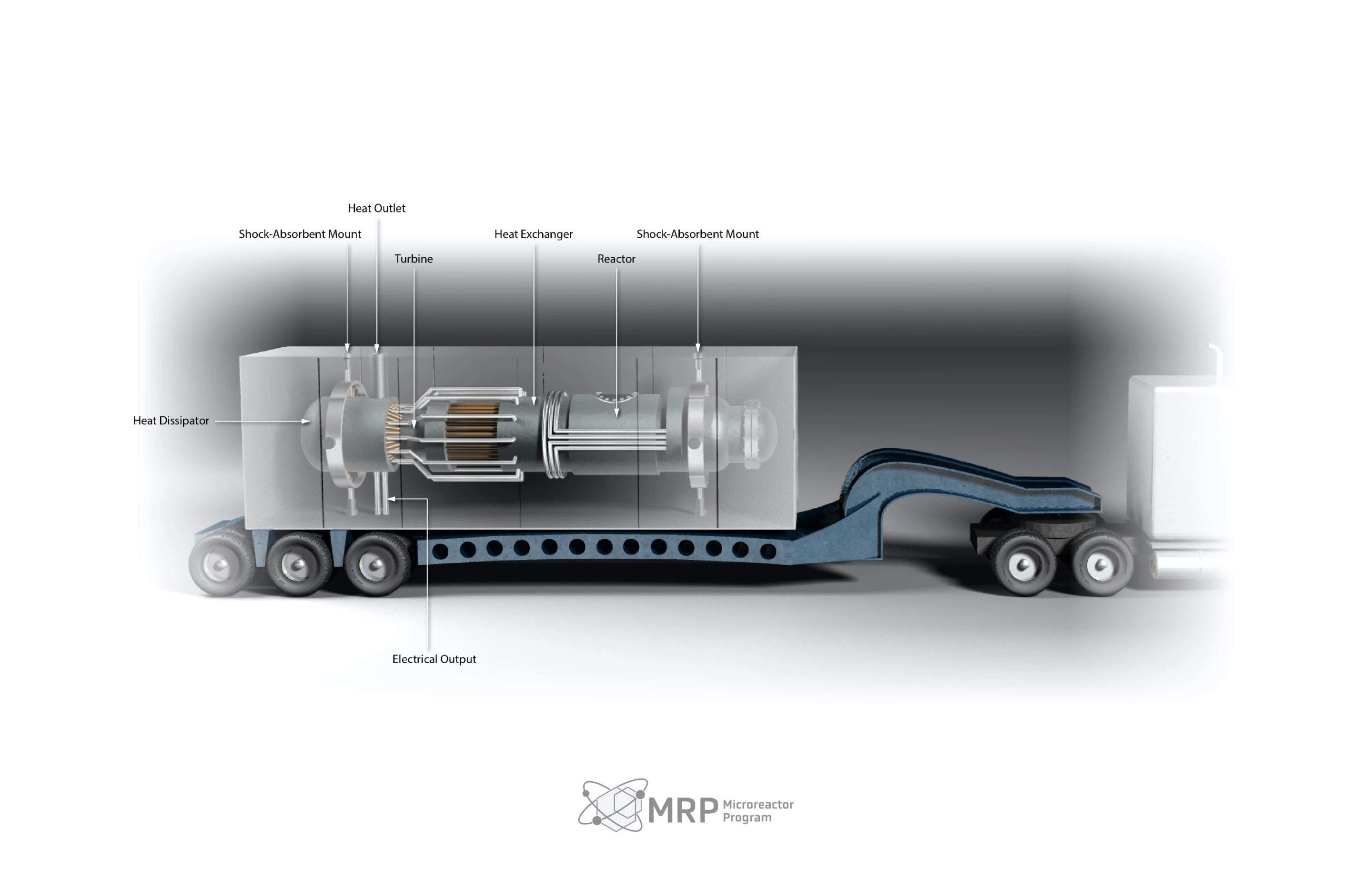

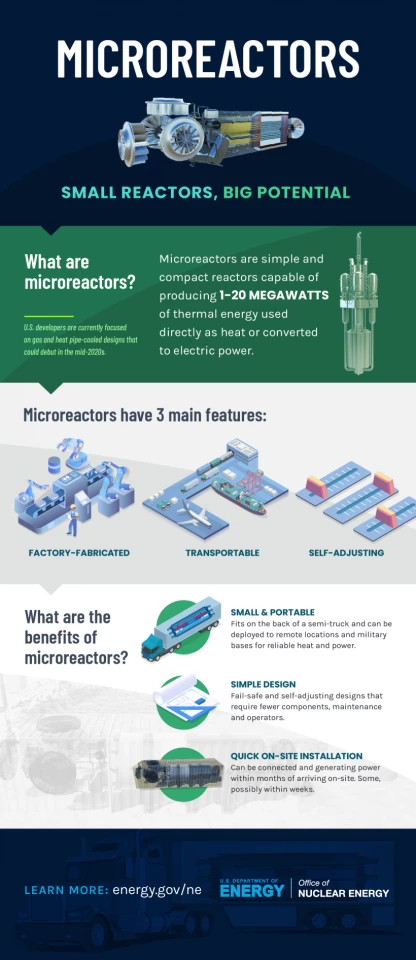

Micro-reactors that produce less than 20 MW are similar to the small reactors developed for nuclear submarines, though they differ in many aspects of their design. Both types of reactors use nuclear fuel that is more highly enriched than in conventional reactors, but micro-reactors are factory-built, modular, and do not always require water for cooling.

This simplified design not only provides electricity, but also direct heat. Because of their large surface-to-volume ratio, micro-reactors are easier to cool and self-regulating. This means that if the nuclear reaction becomes too robust, the heating naturally tamps down the reaction, which eliminates the need for a large crew of skilled operators. In addition, they only need to be refueled once every 10 years.

The idea is that micro-reactors could be built and assembled in factories with modules to order and then shipped in a standard container to Eielson for final installation. If successful, the pilot plant could lead to micro-reactors being used on other military bases, and potentially by remote civilian communities, mining sites, and oil fields, as well as for water desalination and hydrogen production.

"Energy is a critical asset to ensure mission continuity at our installations," says Deputy Assistant Secretary of the Air Force for Environment, Safety, and Infrastructure Mark Correll. "Micro-reactors are a promising technology for ensuring energy resilience and reliability, and are particularly well-suited for powering and heating remote domestic military bases like Eielson AFB.

"This technology has the potential to provide true energy assurance, and the existing energy infrastructure and compatible climate at Eielson make for the perfect location to validate its feasibility."

Source: US Air Force