Using off-the-shelf industrial parts, a team of researchers from the public and private sectors has created a prototype of a small particle accelerator that could have a big impact bringing the technology forward for commercial applications.

If you're familiar with particle accelerators, you know that they're big. And expensive. And they take a long time to build. At the core of CERN's Large Hadron Collider, for example, is a 27-kilometer-long (17 miles) magnet-studded ring. That facility took about 10 years to bring online and had a price tag in the US$5 billion range. Yet, the idea of using excited electrons, the "product" of particle accelerators, could have applications that reach outside of such a purely research-oriented facility if only a way to produce them using more compact and affordable machinery existed.

That was the thinking that drove scientists from a range of facilities, including the US Department of Energy's Thomas Jefferson National Accelerator Facility and energy and defense company General Atomics, to look for ways to make a more affordable, compact electron beam particle accelerator. They succeeded thanks to two new innovations.

Getting a transfer

The first of these breakthroughs was the way in which the accelerator chamber was designed. In creating the prototype, the team members knew they wanted to focus on superconducting radiofrequency (SRF) particle acceleration, like the system found in Jefferson Lab's Continuous Electron Beam Accelerator Facility. Such accelerators are typically lined with a metal called niobium, which becomes superconducting near absolute zero.

For the new prototype, the team started with niobium, but then added a layer of a niobium-tin alloy on top of it. This meant that the chamber could function at a higher temperature, eliminating the need for such intense super cooling.

Next, the scientists covered the outside of the chamber first with a 2 mm (0.08 in) layer of copper cladding, followed by a thicker 5 mm (0.2 in) layer. This design allowed the chamber to more easily transfer heat created during the particle-acceleration process to the outside through a conduction process.

"We basically built a copper thermal blanket on the outside of the cavity by a combination of cold spray and electroplating," said Gianluigi "Gigi" Ciovati, a Jefferson Lab staff scientist who is leading the project. "This provides a high thermal conductivity path for the heat generated on the inner surface to move to the outer surface and then towards the cryocooler."

Thanks to this conduction-based design the system can function at 4 Kelvin (-452 °F), which is twice as high as the temperature needed in larger systems.

Keeping it cool

And that brings us to the second innovation: the cryocooler.

In large particle accelerators, the system is typically cooled using a liquid helium cryogenics plant. Such a piece of machinery is not only expensive to build, but it's also costly to maintain.

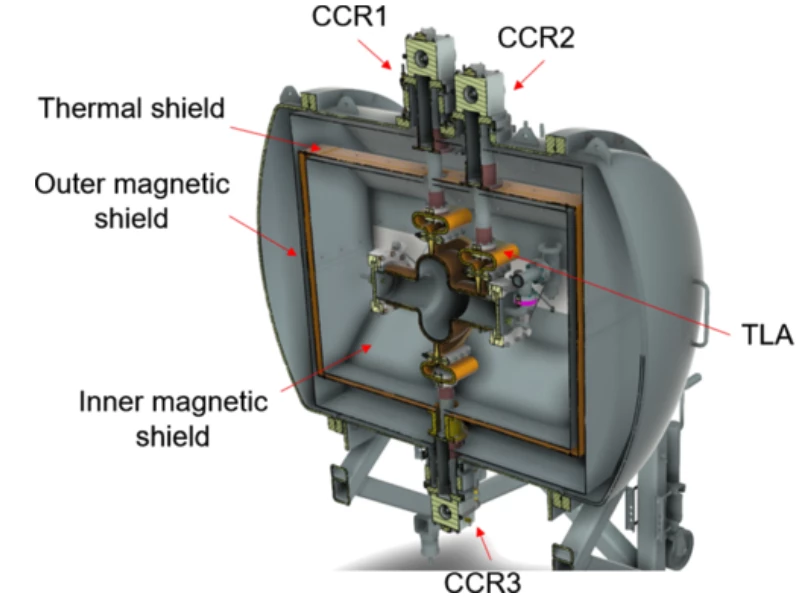

In the new prototype, the team decided to use off-the-shelf cryocoolers, refrigeration systems that are used to – among other things – keep the superconducting magnets cool in many MRI machines. The cryocoolers were mounted with their "cold heads" facing the accelerator chamber and it was found that they were successful in cooling the new conduction-based chamber to the needed 4 Kelvin.

"One of the breakthrough technologies is the ability to cool the cavity by conduction with these compact commercial devices, instead of having large, complex and more expensive cryogenic cooling plants," said Ciovati. "Liquid helium cryoplants won't be needed for the system we are working on."

Testing

The new design was tested at General Atomics in a system known as a horizontal cryostat.

"First, the cryostat was evacuated of air, and then the cavity was cooled below its superconducting threshold and excited with a small RF signal to demonstrate the electrical accelerating gradient," said Drew Packard, a scientist with the Magnetic Fusion Energy (MFE) division of General Atomics. "With the diagnostics, we demonstrated that the conduction-cooled cavity performance achieved the same specifications as the previous liquid helium tests performed at Jefferson Lab."

In fact, the prototype was shown to produce a peak surface magnetic field of 50 milliTesla which, the researchers say, is the highest ever produced from similar setups. The team says that this serves as proof that its new compact accelerator could produce electrons with a 1 million electron-volt (MeV) gain, which allows it to have commercial viability. Such a system could help produce isotopes for nuclear medicine, for example, or help clean up the environment.

"Electron beams are useful in a variety of commercial applications," said Packard. "This compact superconducting accelerator technology has considerable potential for environmental remediation, one example being water purification.

"Untreated water may contain unsafe concentrations of chemicals such as pharmaceuticals or PFAS, as well as harmful pathogens such as E. coli or salmonella. Electron beams are very effective at tearing apart and breaking down complex molecules and organics into more basic particles that are less threatening to human health and the environment."

The team says it will now explore ways to boost the system so that its electron beam can penetrate deeper in materials, while also looking for ways to add modules onto it to make it perform even better.

The research describing the system has been published in the journal Physical Review Accelerators and Beams