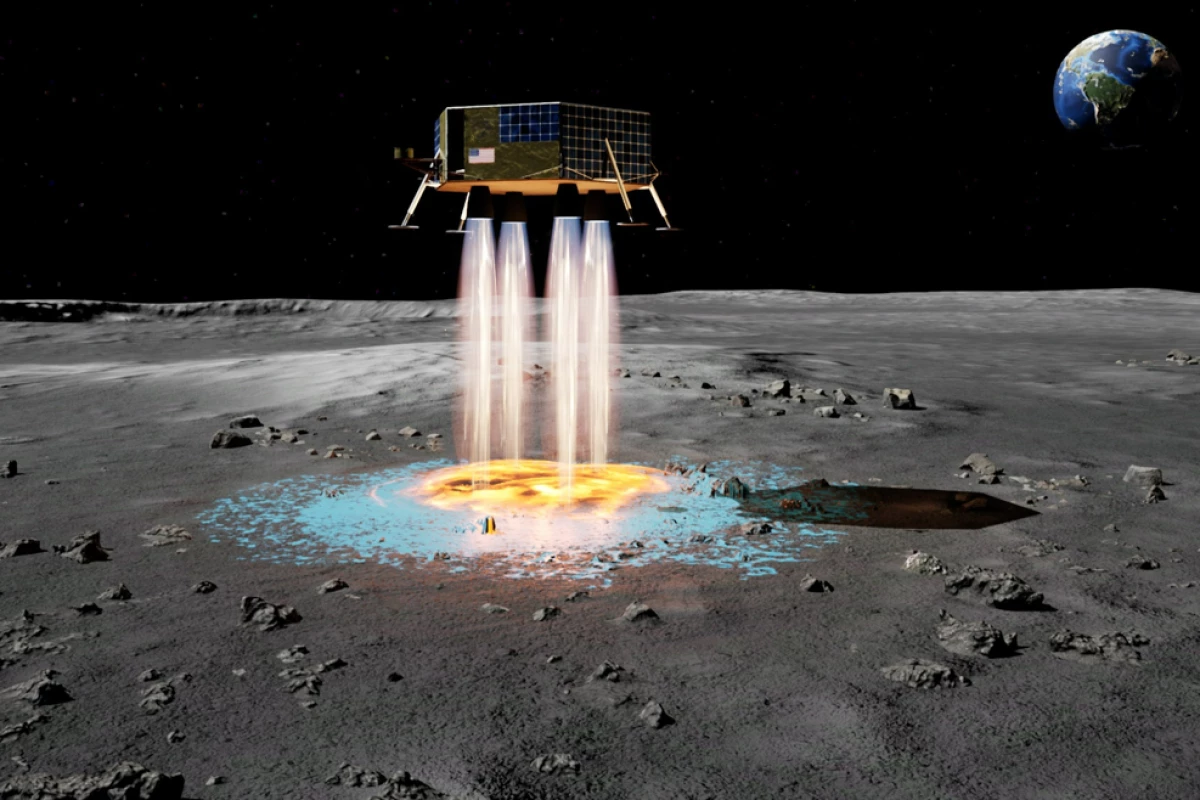

Masten Space Systems is working on a way to protect future lunar landers from the regolith thrown up by their engines as they land, by injecting alumina ceramic particles into the rocket engine plume to glue together lunar dust and create their own landing pads just before touchdown.

NASA's goal of returning to the Moon and establishing a permanent human presence there is ambitious and presents some serious challenges.

Most of the Moon's surface is covered with a regolith, which consists of small dust and larger grains produced by the Moon being pummeled by meteorites for billions of years. Without water or an atmosphere, these particles have sharp, jagged shapes that make them extremely harsh on everything from machinery to spacesuits.

This was hard enough during the Apollo era when the regolith caused their equipment to wear faster than expected, and also posed a hazard to the astronauts' Lunar Module and to the experiments they left on the surface. This is because the blast from the spacecraft's engine turns each particle into a piece of shrapnel flying in a vacuum at 3,000 m/s (9,842 ft/s).

That's bad enough for the Apollo Lunar Module, which weighed in at 15 tonnes fully fueled, but the landers planned for future missions will weigh 20 to 60 tonnes even on landing. These will require larger engines with much more thrust, meaning that as the rocket blasts a deep crater in the surface, the dust thrown up will be much more dangerous over a much larger area.

The obvious solution to this would be to build landing pads like the pads and runways used on terrestrial airports to prevent damage from jet backwash. Unfortunately, it's one of those situations where you can't land until you build a pad, but you can't build a pad until you land.

The logical thing to do would be to build some sort of hardened lander that acts as a pathfinder and then build pads for following landings, but, according to Masten, these pad-building missions would cost US$120 million each, which is not very cost effective.

Being developed in collaboration with Honeybee Robotics, Texas A&M University, and the University of Central Florida under a Phase 1 NASA Innovative Advanced Concepts award, the in-Flight Alumina Spray Technique (FAST) project has completed its year-long preliminary study of the concept.

In FAST, alumina ceramic particles are injected into the rocket plume as the lander descends. These particles coat the surface beneath the lander, consolidating the regolith into a hard pad that has more thermal and ablation resistance. This protects the lander not only during descent, but also when it takes off again to return to lunar orbit.

To make this idea work, Masten and its partners explored the best thickness for the pad, how to determine how the ceramic particles will stick together, how they will survive the heat inside the rocket plume, what the best deposit rate should be, how the particles will adhere to the regolith to form the solid pad while the lander hovers above, and how effective the pad would be in stopping cratering and dust scattering.

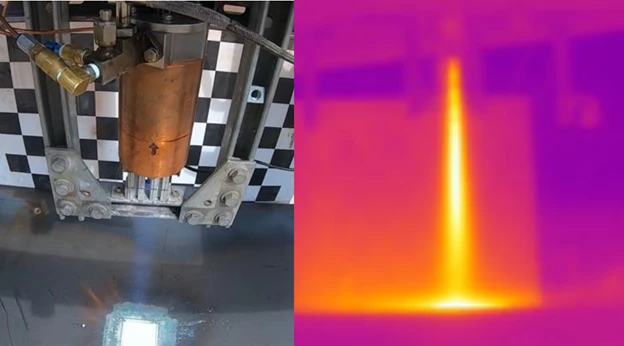

In addition, the team conducted hot-fire landing simulation tests using Masten’s vertical takeoff and landing rockets. From these tests, it was determined that the idea is feasible even for a craft as large as the Artemis crew lander and that the pad building can be controlled by the size and temperature of the engine plume.

In the case of the Artemis lander, this would require alumina ceramic particles about 0.5 mm in diameter being injected into the rocket plume and laying down an initial layer 1 mm thick, then spraying this with particles 0.024 mm in diameter, which would melt as they are introduced into the plume. In 10 seconds, FAST could lay down 186 kg (410 lb) of particles over a 6-m (20-ft) diameter circle. The lander would then hover for another 2.5 seconds while the pad cooled before touching down.

Masten says that the next step will be to test the concept in the lunar environment. If successful, it could bring down the cost of exploring and exploiting the Moon considerably, opening the way for new missions on not only the Moon, but Mars and elsewhere in the solar system.

Source: Masten