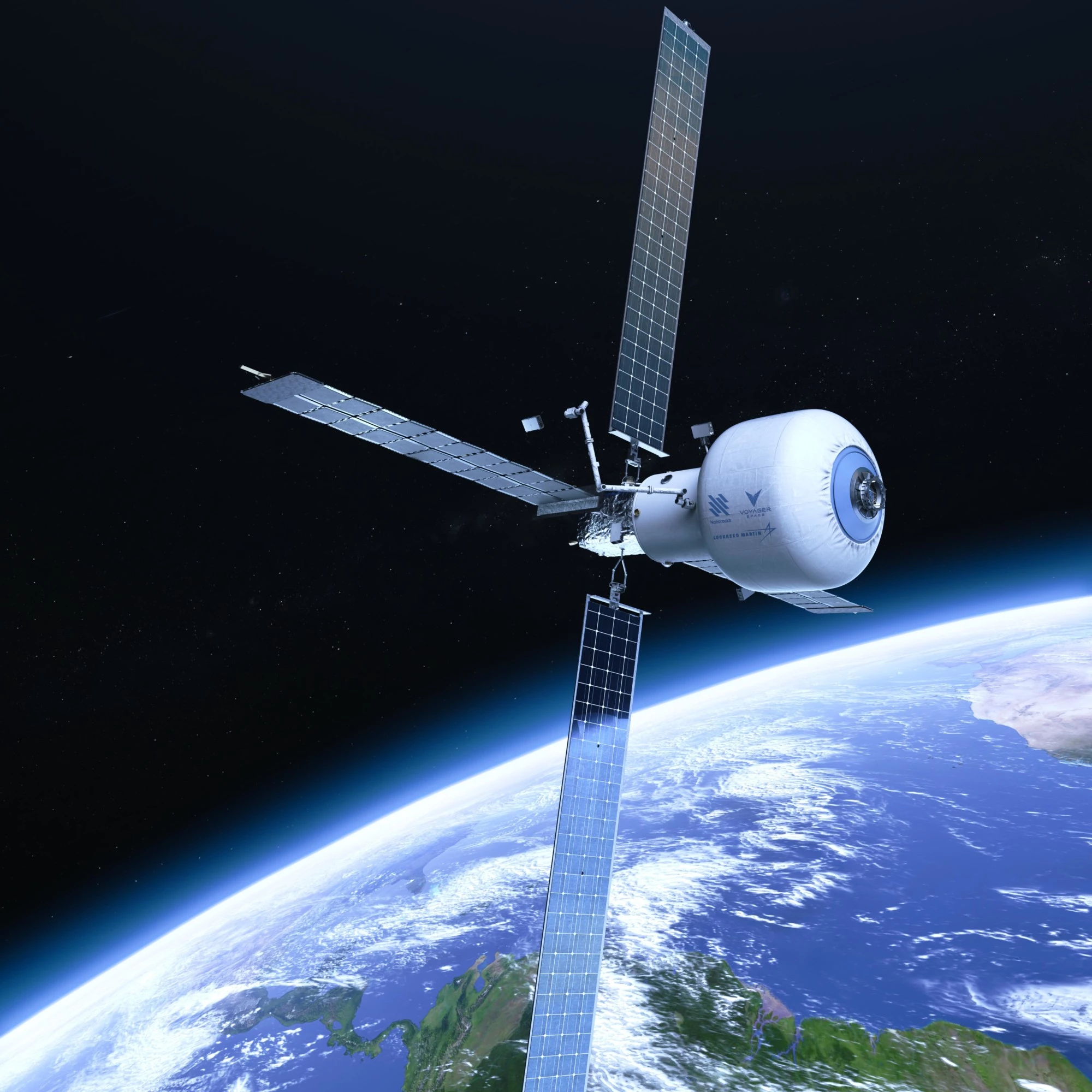

Lockheed Martin, Nanoracks, and Voyager Space have entered into a partnership to launch a permanently crewed commercial space station by 2027. Called Starlab, the semi-inflatable platform will be available to the US government and private industry.

With the International Space Station (ISS) slated for retirement and disposal by 2030, the United States is looking to private companies to provide replacements before that date under NASA's Commercial Low-Earth Orbit Destination (CLD) project. One of these stations is Starlab, which could be the first-ever free flying commercial space station.

The purpose of Starlab is to carry out a wide variety of activities, including general science, materials research, plant growth, astronaut training, and tourism. In addition, it will continue an American presence in space at a time when China is pursuing its own human spaceflight program.

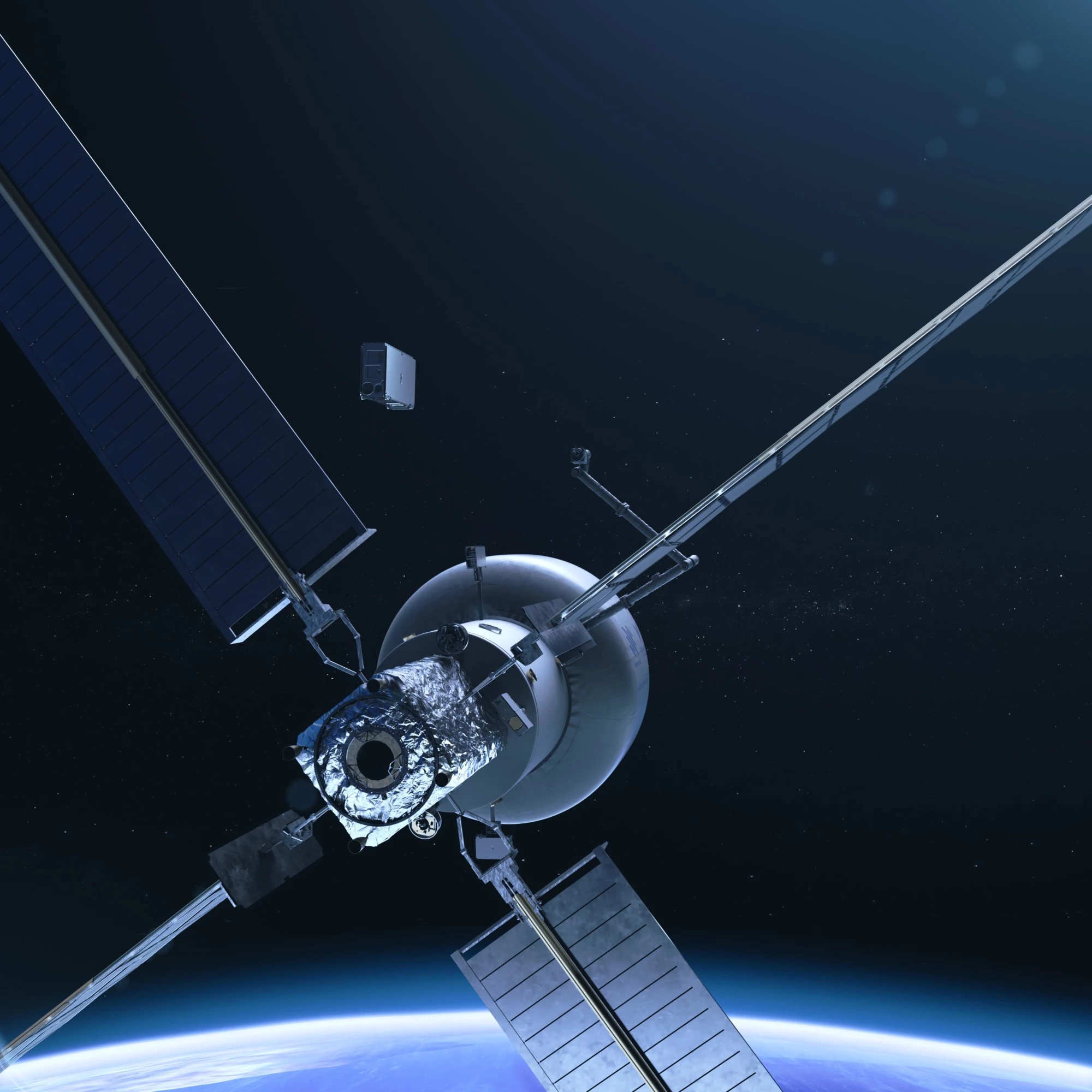

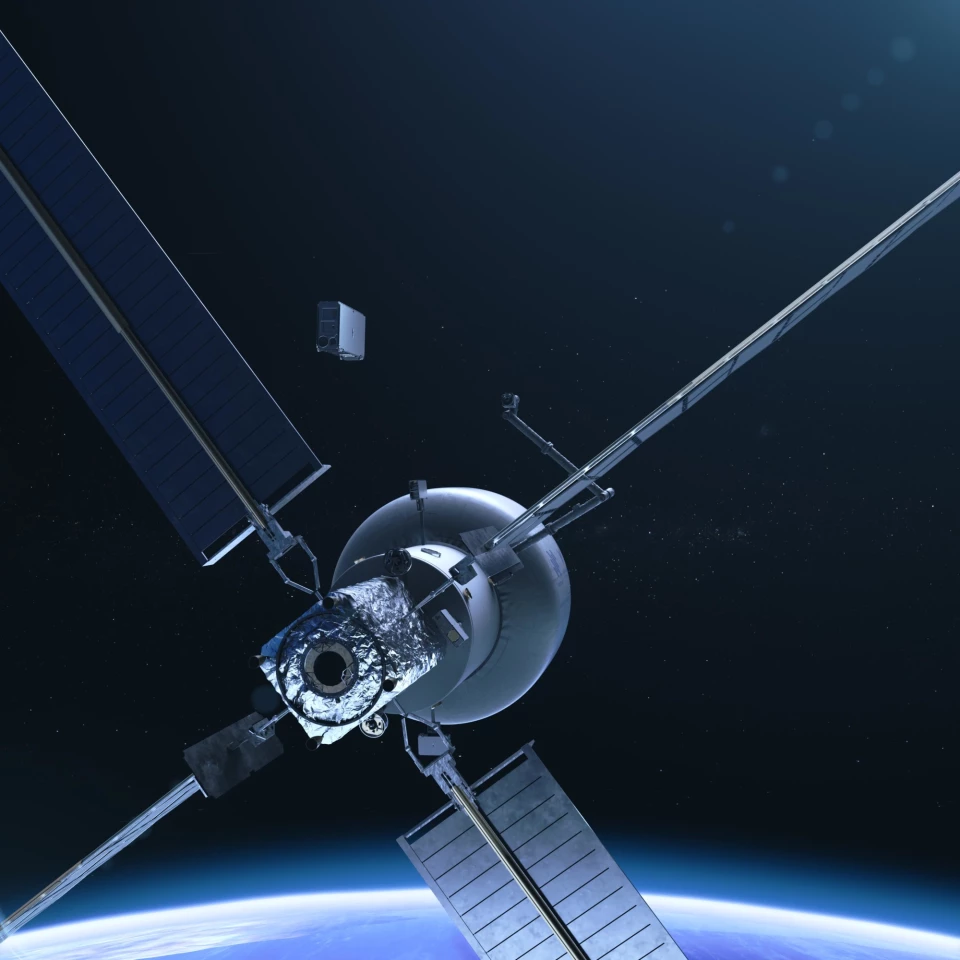

Starlab's development will be led by commercial space services provider Nanoracks, with Voyager Space handling the business side. Lockheed Martin will build and operate the station. In its current iteration, it consists of a large inflatable habitat module and a metallic docking node. It will have a volume of 340 m3 (12,000 ft3) and four solar arrays totaling 60 kW. Meanwhile, a regenerative Environmental Control and Life Support System (ECLSS) will support a permanent crew of four astronauts plus visitors. There will also be a robotic arm to handle cargo ships and outside experiments.

"We’re excited to be part of such an innovative and capable team—one that allows each company to leverage their core strengths," says Lisa Callahan, vice president and general manager, Commercial Civil Space at Lockheed Martin. "Lockheed Martin’s extensive experience in building complex spacecraft and systems, coupled with Nanoracks’ commercial business innovation and Voyager’s financial expertise allows our team to create a customer-focused space station that will fuel our future vision. We have invested significantly in habitat technology which enables us to propose a cost-effective, mission-driven spacecraft design for Starlab."

Sources: Lockheed Martin, Nanoracks