Concrete

-

A team of researchers might soon have you walking on desert sand, no matter how far from the dunes you might live. This group of engineers has developed a method to transform it into a new construction material that's perfect for pavements.

-

Researchers in South Australia have found a way to funnel a byproduct of the highly destructive process of lithium mining into making stronger and more durable concrete.

-

Although we've heard a lot about how 3D-printing concrete homes speeds up the construction process, you still have to wait up to 28 days for the concrete to sufficiently cure. A new printable substitute, however, is ready to go in just three days.

-

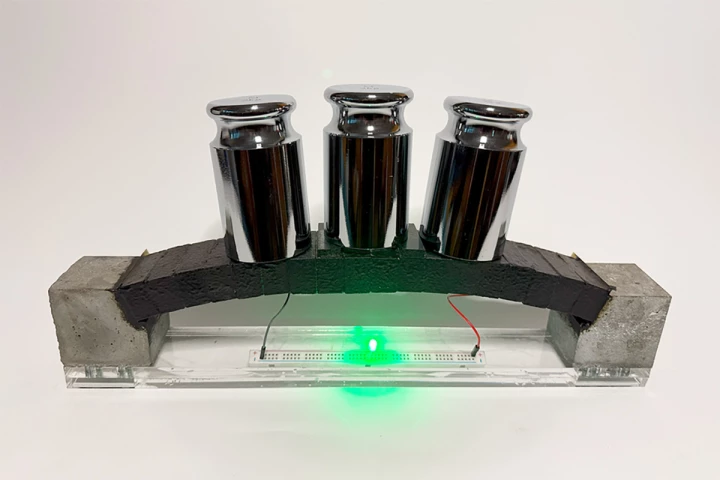

Scientists have been working on enhancing concrete to store energy. That includes researchers at MIT, who found a way to combine cement, water, and carbon black to create a 'supercapacitor' for this purpose back in 2023. It's now 10x better at this.

-

Once a harmless drifter in the Sargasso Sea, an algae known as sargassum is now flooding beaches, from Brazil to the Caribbean, with stinky piles. But some clever researchers have mixed it into concrete creating a new, ultra-light building material.

-

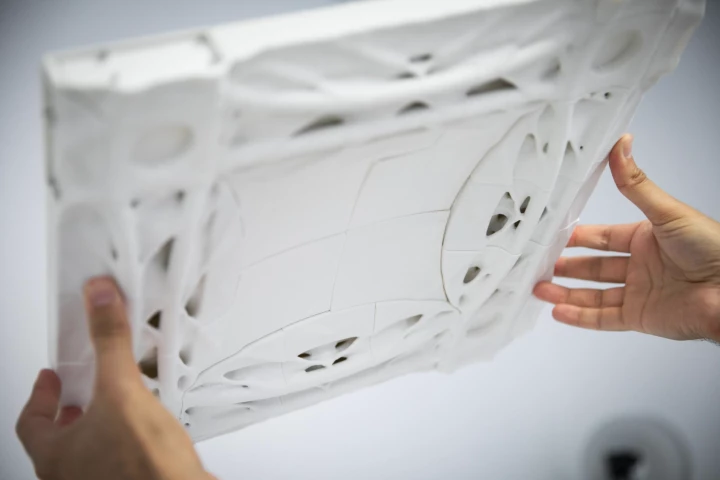

Using intricate geometry found in nature and refined through aerospace and biomedical design, scientists have now 3D-printed these forms into concrete to boost strength and capture carbon – creating a scalable material that benefits people and planet.

-

Using more sludge and less slag in their recipe, researchers were able to create a material that's stronger than even today's enhanced cements and highly resistant to corrosion by acid. It could solve a serious problem facing sewer pipes worldwide.

-

Engineers from Montana State University have developed a building material using the root-like mycelium network of a fungus. It's the first time fungal mycelium has been tested as a scaffold for living materials.

-

Researchers have found a way to take waste concrete from demolition sites and turn it into fresh new concrete that has a strength not seen before from such a product. The breakthrough could lead to significant emissions reductions in the building sector.

-

This strange white paste might not look like much, but it could not only solve the sand shortage, but make the cement manufacturing process absorb carbon dioxide instead of emitting it. Scientists grew this stuff out of seawater, electricity and CO2.

-

A reusable formwork design for molding concrete into vaulted floors using sophisticated structural geometry uses 60% less concrete and 90% less steel compared to traditional methods. It's also inexpensive and doesn't require special skills.

-

Situated in Yangpo Village atop the Gaoligong Mountains, the Nujiang Grand Canyon Bookstore blends contemporary architecture with nature. Offering panoramic views of the Nujiang River, the innovative project connects modern design with local heritage.

Load More