Scientists at Oxford University have developed a novel sensor made of incredibly thin strands of sapphire that can withstand extreme heat and radiation. The breakthrough is billed as a solution to a 20-year problem in the field, and the scientists behind it believe their durable new sensor could be put to work in the harsh environment of nuclear fusion reactors and enable more streamlined air travel.

The type of sensor at the heart of this research is known as a Fiber Bragg grating (FBG) sensor, which can be used to monitor things like temperature and strain in optical communications systems. These typically come in the form of silica optical fiber, but this design begins to run into trouble at operating temperatures of less than 1,000 °C (1,832 °F).

FBGs made from sapphire fibers promise greater stability at higher temperatures, having been demonstrated at up to 1,900 °C (3,452 °F), which could see them put to use in extreme environments such as monitoring gas turbines in jet engines. In addition, sapphire is resistant to radiation, which makes it suitable for use in nuclear reactors and in space.

But sapphire FBGs present issues of their own. These fibers are very fine and measure less than half a millimeter wide, but this is still far thicker than the wavelength of light, which creates ample opportunity for injected light to bounce around at different wavelengths inside. Because a particular wavelength of reflected light is what the sensor relies on to read temperature, for example, this extra noises confuses the signal and renders the sensor useless.

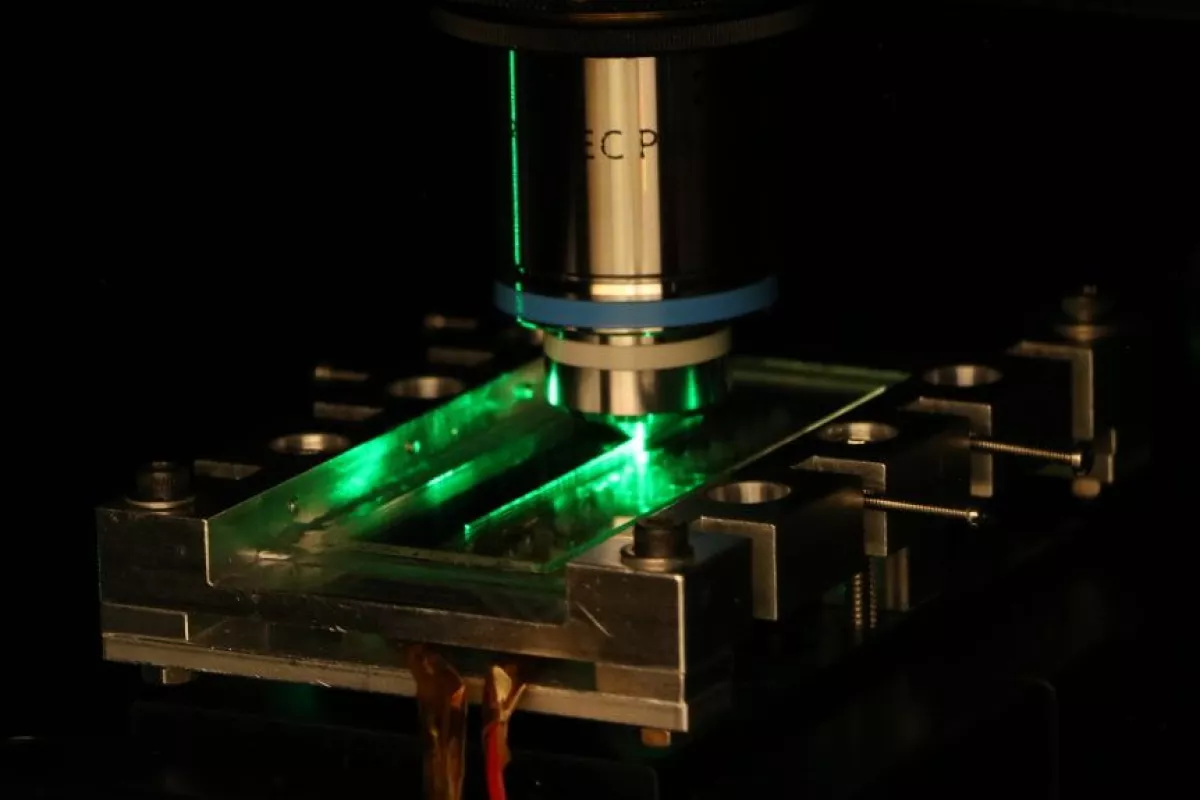

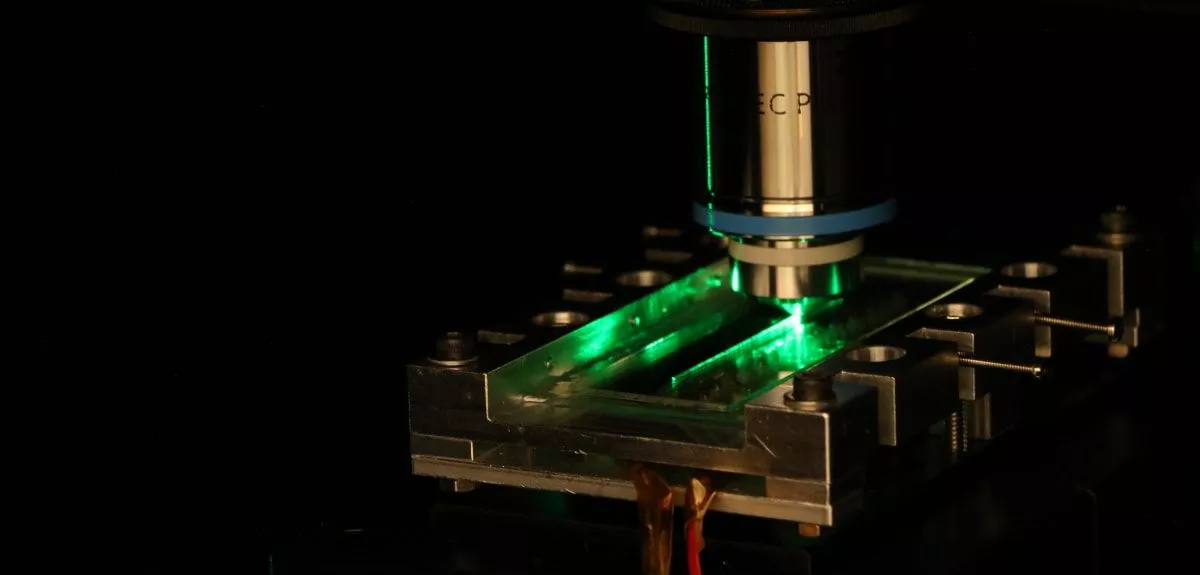

To overcome this, the Oxford team used femtosecond lasers to etch a channel along the length of the sapphire fiber to guide the light on a straight and narrow path, with the groove measuring one-hundredth of a millimeter in diameter. This resulted in a sapphire FBG sensor predominantly reflecting a single wavelength of light.

"These sapphire optical fibers will have many different potential applications within the extreme environments of a fusion energy power plant," said Rob Skilton, from the UK Atomic Energy Authority (AEA). "This technology has the potential to significantly increase the capabilities of future sensor and robotic maintenance systems in this sector, helping UKAEA in its mission to deliver safe, sustainable, low carbon fusion power to the grid."

In its current form, the sapphire fiber sensor measures just a centimeter (0.4 in) long, but the researchers believe developing versions of several meters in length is entirely possible. With regard to aerospace, this would allow temperature measurements to be made throughout a jet engine, for example, allowing for on-the-fly adjustments to engine conditions to improve efficiency of the flight.

"This is exciting news and yet another important scientific achievement resulting from our long-standing partnership with Oxford University," said Mark Jefferies, Chief of University Research Liaison at Rolls-Royce. "This fundamental research could in time enable more efficient and accurate multi-point temperature measurement in harsh environments, improving control, efficiency, and safety. We look forward to working with the University of Oxford to explore its potential."

The research was published in the journal Optics Express.

Source: Oxford University