A glue that performs at a high-level in wet environments could bring about all sorts of possibilities in areas like surgical care and ship maintenance. A somewhat common approach to this problem has been trying to replicate the freakish ability of mussels to bind themselves to boats and jetties, but a team from Singapore's Nanyang Technological University is coming at it from a slightly different angle by developing a glue that hardens when an electrical charge is applied.

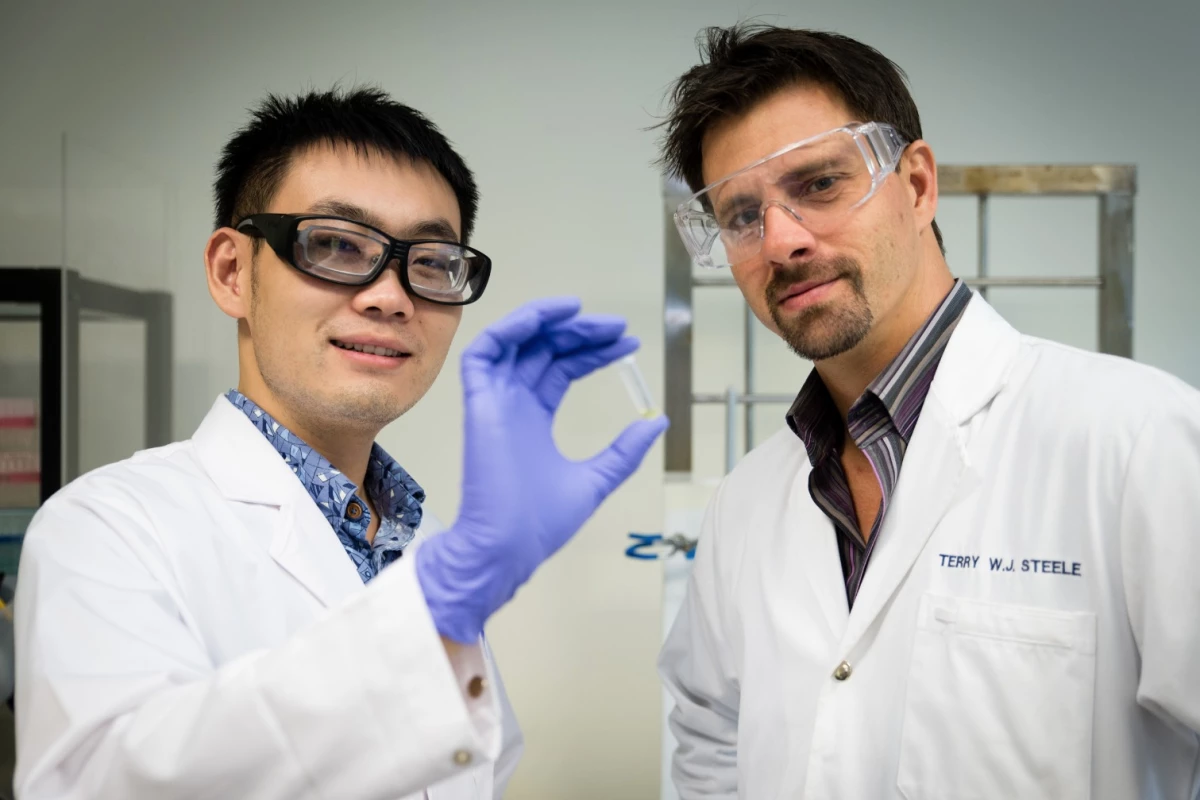

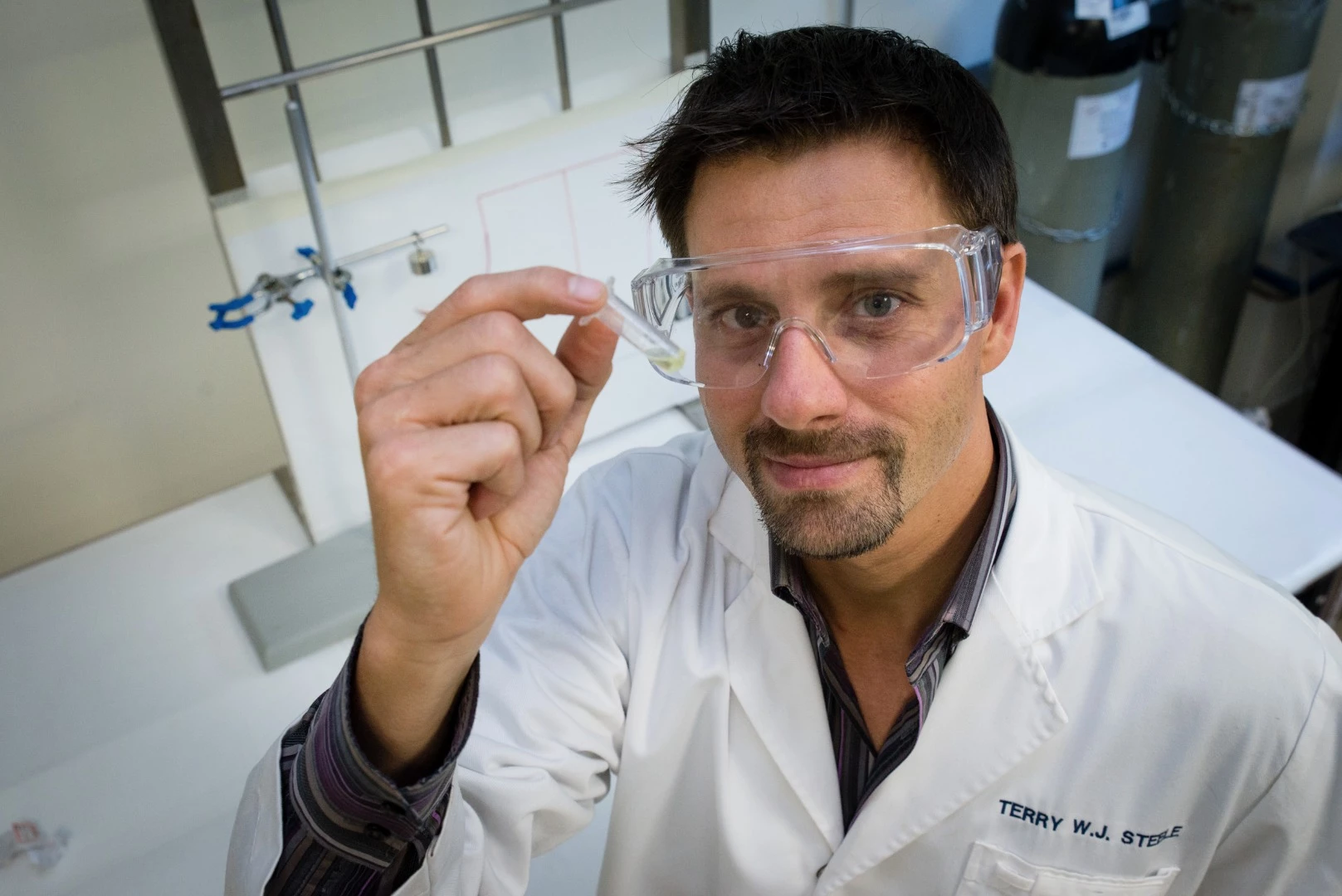

As the team's lead scientist Professor Terry Steele points out, most glues don't work when they're wet, in the same way that sticky tape won't stick to a wet surface because the adhesive will stick to the water rather than the surface. Steele and his team have been at work for more than a year, crafting a new form of adhesive that can perform its job in wet conditions, such as underwater or in the human body.

They used hydrogels comprising carbon molecules known as carbenes, which are grafted onto tree-shaped plastic surfaces called dendrimers. Applying an electrical charge kicks the carbenes into action and sees them hook onto any nearby surfaces.

A particularly promising aspect of this approach is that the length of time the voltage is applied to the gel dictates how many of these hooks the carbenes create. This means by controlling the charge you control the hardness of the glue, and in turn, its suitability for different applications. The team call this process "electrocuring."

"For example, if we are gluing metal panels underwater, we want it hard enough to stick for a long time," says Steele. "However, for medical applications, we want the glue to be more rubber-like so it wouldn’t cause any damage to the surrounding soft tissues."

Another attribute that could prove a huge plus of the glue, which the team has nicknamed "Voltaglue," may be the ability to reverse the process. That is, to cancel out the glue's adhesive properties to allow for simple dismantling of ship parts, for example, negating the need for nuts and bolts.

Steele and his team are now working to reduce the time it takes for the glue to harden, from around half a minute down to just a few seconds. They will also conduct further research into the possibilities of making it "reversible."

The research was published in the journal Nature Communications.

Source: Nanyang Technological University