According to a recently-granted patent,Airbus is exploring the potential of creating a new breed ofversatile, modular aircraft that would see detachable passengercabins slot into a hole in an aeroplane's fuselage. The concept hasthe potential to revolutionize air travel, while providingsignificant savings for airlines by reducing the time that planesspend idle on the ground.

After landing, and prior to launch, aconventional aeroplane has to sit on the tarmac waiting for anecessary but glacial set of events to unfold. This periodof inactivity, which is the combined result of a number of factorsincluding the embarking of passengers, luggage and freight, costsairlines time and money.

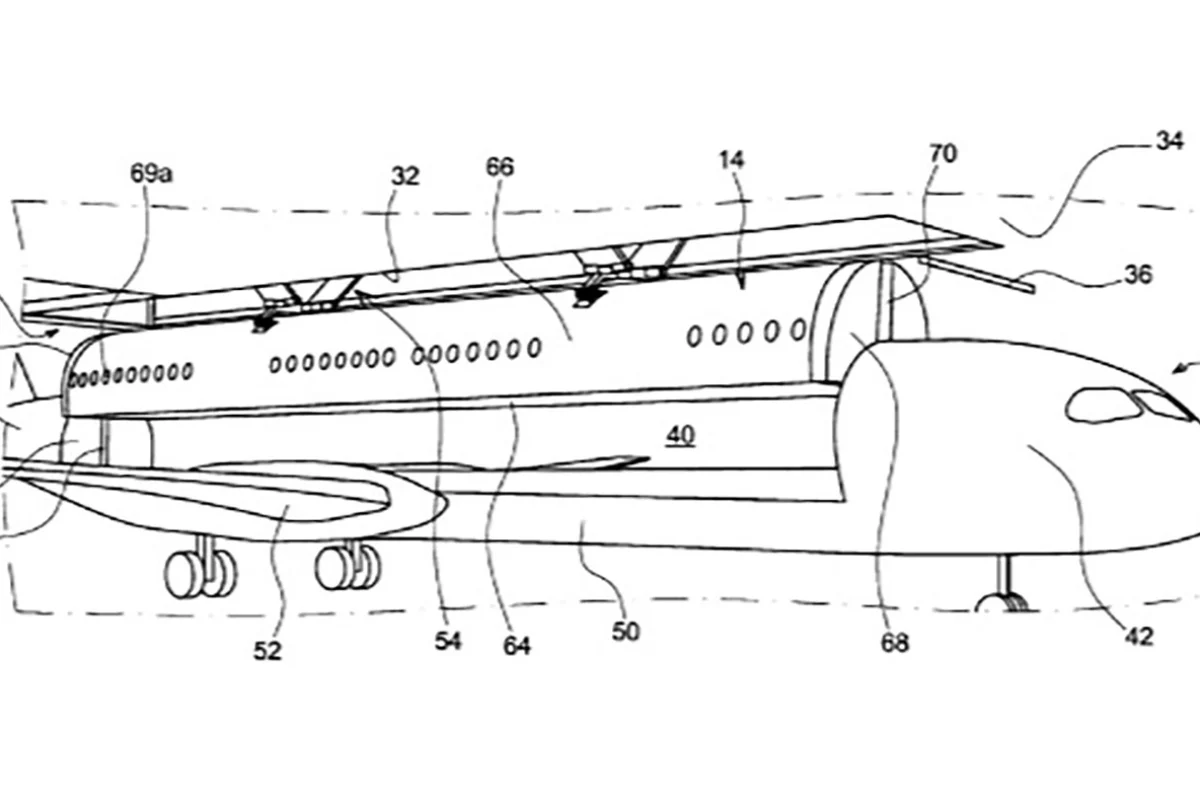

The newly patented concept would seekto remedy these limitations by taking a more modular approach to the wholesituation. Instead of a single hull, aeroplanes would essentially bebuilt with a hole in their fuselage between the nose cone and thetail section, into which modular compartments could be fitted andremoved.

The compartments, which could take onthe purpose of a passenger, luxury passenger or freight unit, wouldbe transferred between the aircraft and airport via a docking module,which according to Airbus would (ideally) be integrated into airportterminal buildings.

Such a system would allow passengers tobe seated, or cargo to be loaded over an extended period of timewhile the cabin was docked in the terminal without the need toimmobilize the aircraft beyond the time necessary to carry outpreflight operations such as refuelling, the cleaning of a cabin, andthe execution of routine technical checks. This would dramaticallyreduce inactivity time, with the effect of increasing the overallnumber of flights, and therefore profitability of the airline.

Furthermore, the implementation of amodular system would afford airlines an unprecedented level offlexibility in the make up of their fleet. Ordinarily, each aircraftis purpose built to serve as, for example, a passenger or freightservice. Therefore, under the current integrated aircraft designs, anairline would have to purchase additional aircraft or make costlymodifications to existing units to serve multiple roles.

A modular approach to aircraftconstruction would allow an airline to switch the purpose of a planein a matter of hours simply by replacing the cabin, ready to cater tothe short term needs of the airline with a level of cost effectiveefficiency that cannot be matched by single-hull aircraft.

It's fair to say that such a systemwould represent a huge leap forward in the commercial aviationsphere. But of course, it's very early days. The cost of creating andimplementing such a system, paired with unforeseen complications inthe development process, as well as the significant alterations you'dhave to make to current airport architectures, means we won't betaking a ride in a modular airliner any time soon.

Source: USPTO