Airbus is moving ahead with its vision of aircraft with active wing control, following successful wind tunnel tests at its facility near Bristol, England. The company is working to mimic the behavior of bird flight with wings that adapt their shape on the fly to optimize aerodynamics, making for more efficient aircraft with lower carbon footprints.

The eXtra Performance Wing project was borne out of a similar Airbus project called AlbatrossOne, which in 2019 saw engineers fly a scale-model airplane with flapping wing tips. Inspired by the albatross wing, the wings featured semi-aeroelastic hinges that responded to turbulence and gusts of wind to lessen the load on the airframe, reducing the need for reinforcing structures and saving considerable weight as a result.

Launched last September, the eXtra Performance Wing demonstrator is a continuation of this thinking, consisting of a scaled-down Cessna jet that can be fitted with gust sensors, pop-up spoilers and multifunctional trailing edges. The platform will be used to rapidly test and develop these types of technologies, with a view to improving aerodynamics for future aircraft.

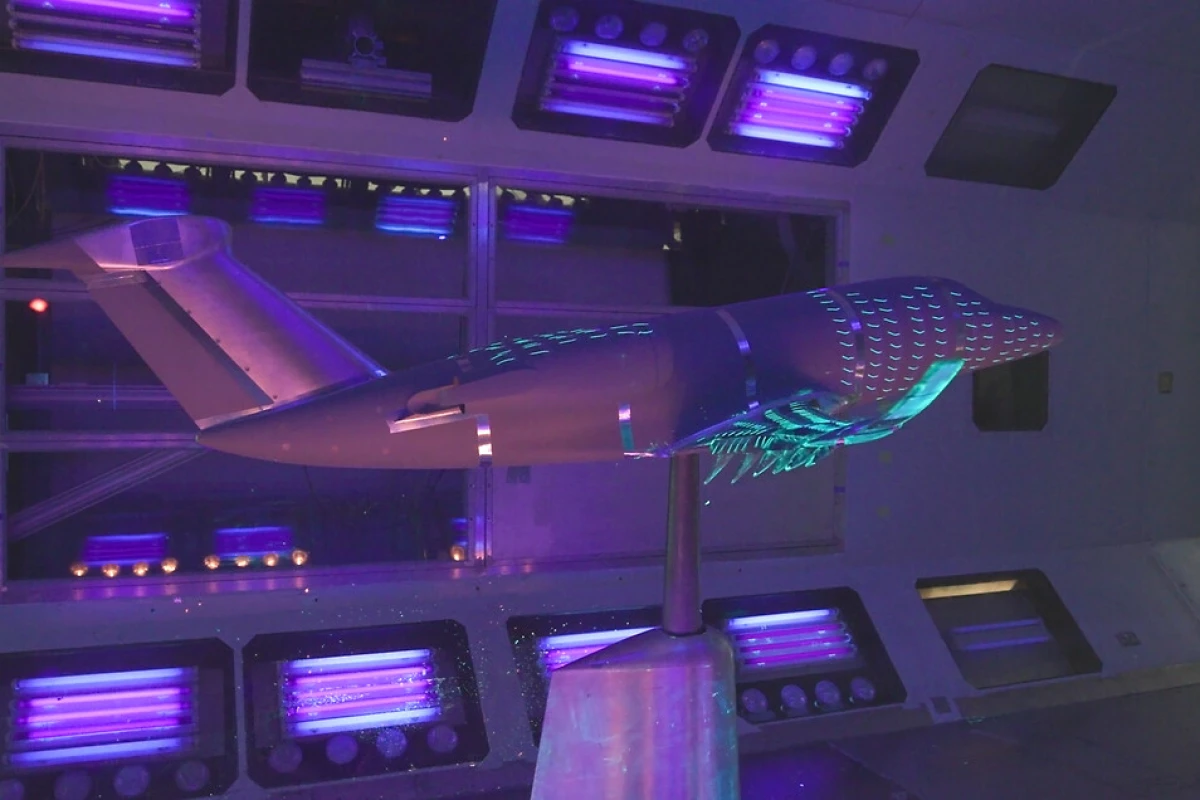

“The scaled demonstrator will integrate and fly breakthrough wing technologies using a remote-controlled Cessna Citation VII business jet platform in representative flight conditions,” explained Oliver Family, Head of eXtra Performance Wing UK. “The partly 3D-printed wind-tunnel model – expertly built by the aerodynamics team at Airbus’ low-speed, wind-tunnel facility in Bristol – is a scaled-down version of the Cessna jet, incorporating the lightweight, long-span design of the eXtra Performance Wing that will provide the emissions benefits we are striving for.”

Aerospace engineers regularly turn to bird flight in an effort to improve aircraft performance. We've seen research projects show how shape-shifting wings can make aircraft more efficient, and others that demonstrate how owls could inspire planes that fly more quietly and handle strong winds. Airbus hopes that by exploring the possibilities of biomimicry at its Filton wind tunnel near Bristol, it can soon get some of these technologies off the ground.

“Airbus’ state-of-the-art low-speed wind-tunnel is a fantastic way to validate our concepts before flight tests,” added Oliver Family. “Our computational aerodynamic analysis capability is world class, and the wind tunnel provides another valuable way to measure the performance and capabilities of the aircraft before flight testing. The technologies we have tested in the Filton wind tunnel – many inspired by biomimicry – will now be rapidly integrated for flight testing.”

Source: Airbus