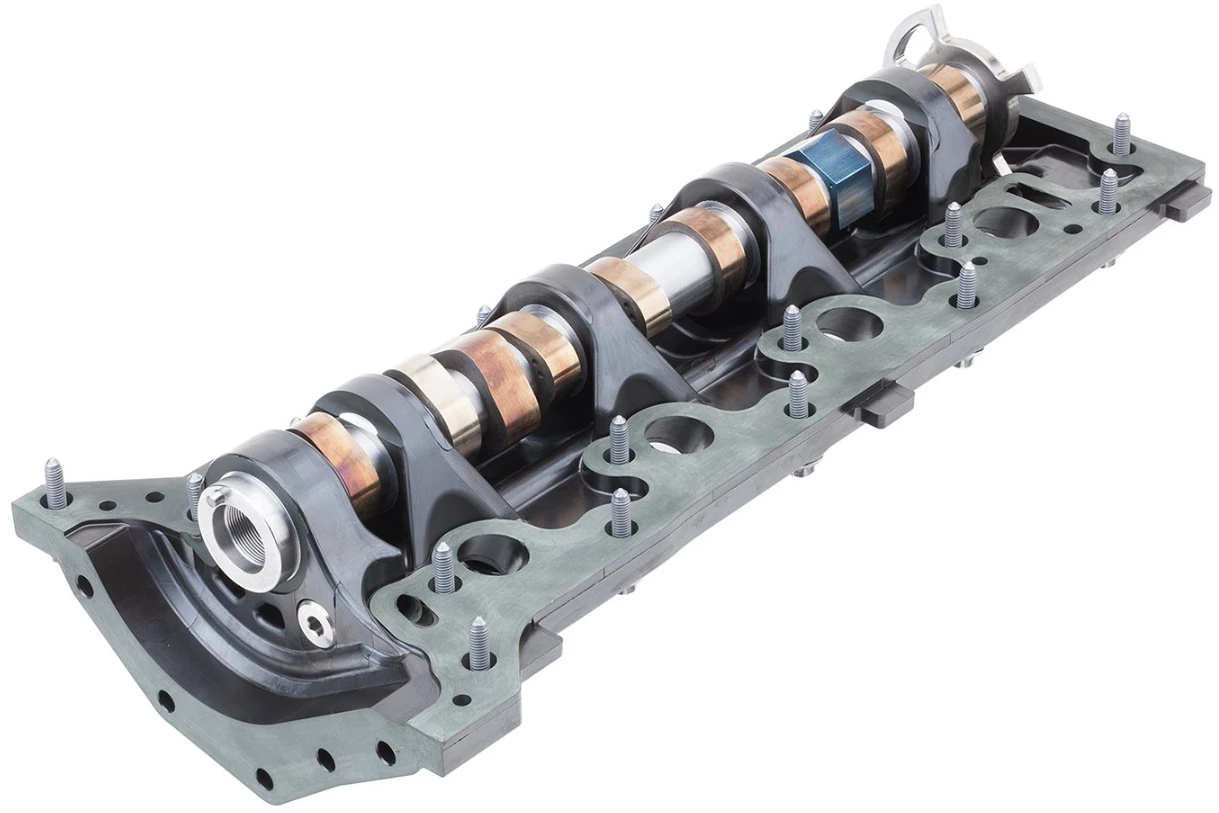

If there's one way of getting automobiles to use less gas, it's by lowering their weight – and the engine is a particularly heavy part of the car. With that in mind, European researchers have now created a plastic camshaft module, which they claim offers more advantages than simply being lightweight.

The prototype component was designed in a collaboration between Germany's Fraunhofer Institute for Chemical Technology, automotive parts manufacturer the MAHLE Group, the Daimler automotive company, Belgian plastics manufacturer SBHPP/Vyncolit, and French plastics company The Georges Pernoud Group.

Instead of the usual die-cast aluminum, the new module is made of a fiber-reinforced thermoset polymer – "thermoset" means that it starts out as a soft resin, which is cured into a solid through the application of heat.

And yes, the finished camshaft module is indeed lighter than a comparable aluminum product. Given that it's located on top of the engine, this is a particularly important consideration, as it not only reduces the engine's total weight but also lowers its center of gravity.

Additionally, though, the plastic module is reportedly better than aluminum at absorbing noise-producing vibrations, it requires less energy to manufacture, the molds used in its production last longer, and it requires much less in the way of finishing work after the casting process is complete. As an added bonus, it can be manufactured all in one piece, reducing assembly time.

It should be noted that the fiber-reinforced thermoset polymer is just one quarter as stiff as aluminum, although the design of the camshaft module is claimed to compensate for this shortcoming. When all was said and done, one of the prototypes reportedly "demonstrated flawless functionality in a state-of-the-art internal combustion engine" after 600 hours of bench testing.

The module was specifically claimed to stand up well to high engine temperatures, along with mechanical and chemical stresses. More testing is planned, though, to see how the gas forces created by the combustion process affect its noise-reducing characteristics.

Source: Fraunhofer