Anticipating a boom in nuclear energy, the US Department of Energy’s Manufacturing Demonstration Facility (MDF) at Oak Ridge National Laboratory is using 3D-printing to speed up the building of power plants while bringing down costs.

Nuclear power in the West is undergoing a renaissance while aggressive construction programs continue in Asia and more are planned in Africa and other parts of the world. There are a number of reasons for this, but the pressure from projected power demands, especially from the boom in data centers, means that many plants of various designs will need to be built in years or even months instead of the decades of earlier generations.

Not only is speed a factor, so is cost. Nuclear plants are notoriously expensive to build, but it isn't the reactor that gobbles up the money. The real big numbers on the expense side of the ledger is the mundane concrete and steel civil engineering needed to house the nuclear tech and the electrical gear that make up over half the budget. This work also takes the most time to complete.

The bottom line: reduce the cost and speed of the engineering and the entire project benefits.

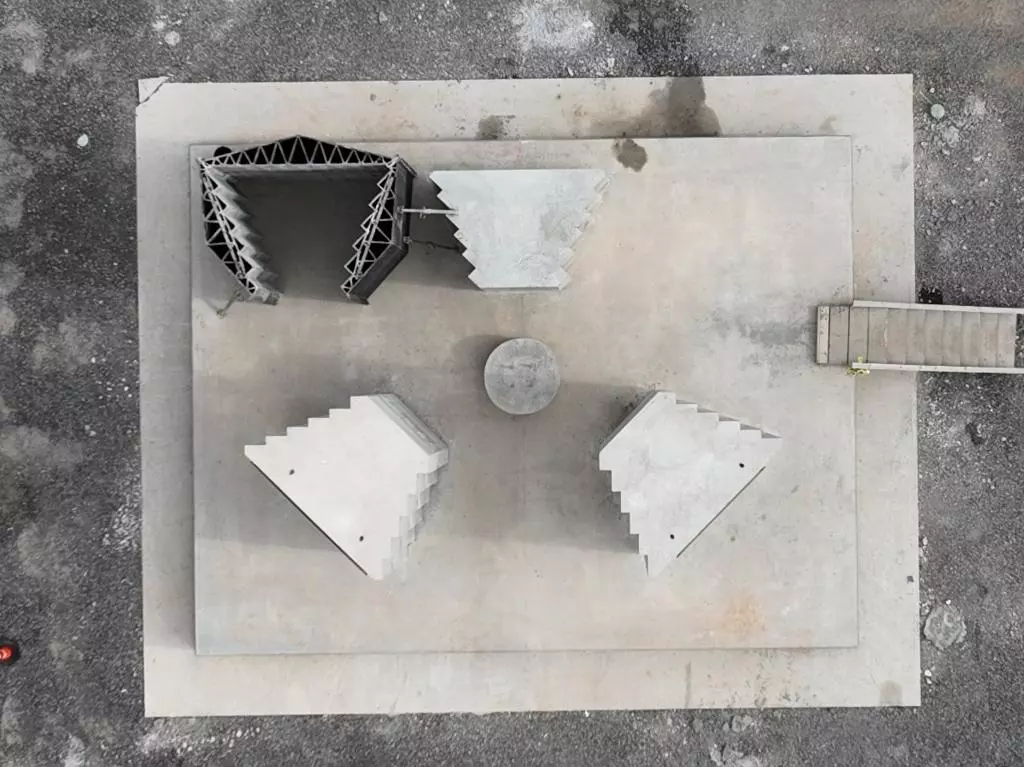

As part of the Generation IV Hermes Low-Power Demonstration Reactor project being built at the Oak Ridge campus in Tennessee in partnership with Kairos Power, MDF is testing the use of 3D-printed polymer forms to build the thick concrete bioshield used to contain the reactor vessel and isolate it from the outside environment. These forms are assembled around networks of steel rebar and concrete then poured into the mold.

According to Oak Ridge, the new polymer forms are fast to produce and can be reused as required. In addition, they are more precise than conventional steel or wooden molds, can be configured into complex shapes, and allow for more precise formations. This allows complex structures to be assembled onsite in a matter of days rather than weeks. In addition, reusable polymer molds can reduce the amount of timber needed for plant construction by 75%.

In addition to showing off the possibilities of 3D printing in nuclear construction, the Hermes reactor allows for extensive testing of the resulting structures, including their ability to maintain integrity under high load stresses.

"At ORNL, we’re showing that the future of nuclear construction doesn’t have to look like the past," said Ryan Dehoff, director of the Manufacturing Demonstration Facility. "We’re combining national lab capabilities with MDF’s legacy of taking big, ambitious swings – moonshots that turn bold ideas into practical solutions – to accelerate new commercial nuclear energy."

Source: ORNL