Battery advances are starting to come thick and fast as massive investment in the segment begins to bear fruit. California's Enevate has been chipping away at silicon anode technology since 2005, and now the company says it's managed not only to achieve an incredibly fast charging solution for lithium-ion EV batteries, but one that handily boosts energy density as well.

The typical current-gen lithium battery anode is made of graphite. Replacing it with silicon, says Enevate founder and CEO Benjamin Park, would give you an instant boost of 25% in energy density and enable super-quick charging if you could just get around the fact that it swells by 400% when it charges up, eventually cracking and degrading the battery surfaces. This kills the battery within a few hundred cycles.

Enevate's solution can be conceptualized as a hard, porous, conductive film, with each pore having its own small "balloon" of silicon inside. Thus, the silicon can swell and deflate as much as it likes without causing any of the cracking issues, and you get yourself a silicon anode that gives your battery some pretty impressive properties and a lifespan that's no longer a deal-breaker.

Those properties include an energy density boost of around 30% over current-gen tech, up to 350 Wh/kg, as well as the ability to charge extremely quickly, at rates that could effectively put 400 km (250 mi) of range into your battery in five minutes. That's not far off how fast it is to fill a tank with gasoline, and it'd be a game-changing leap forward if the infrastructure was there to move that amount of energy.

They also charge well at temperatures well below freezing, something other lithium-based batteries can struggle with, and the company says its electrodes don't suffer from the kinds of lithium deposits that can lead to the dangerous dendrite formation that can short out batteries and lead to them catching fire. So they'd appear to be safer than the status quo, as well.

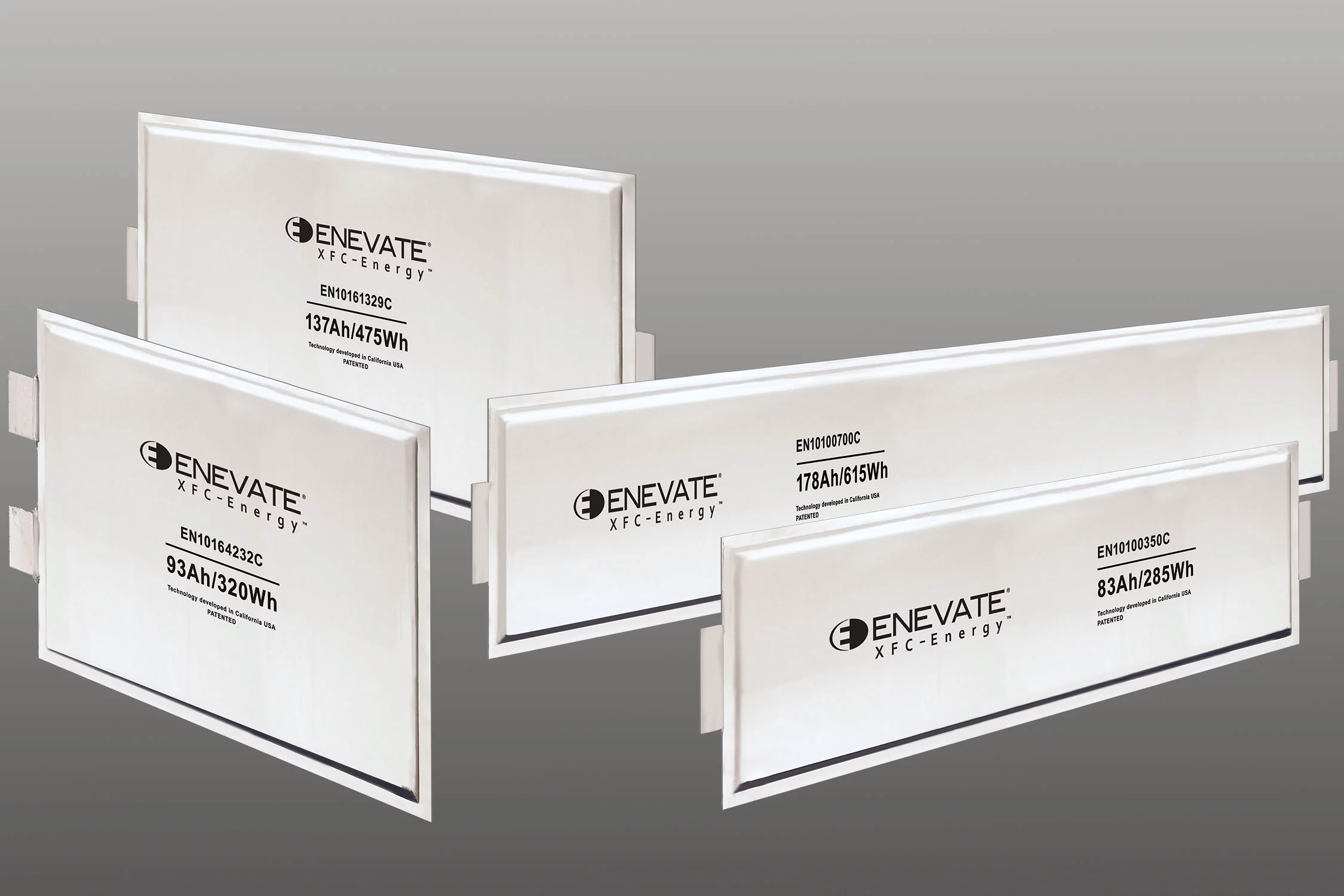

With some US$111 million in investment from major companies, including LG, Samsung, Mitsubishi, Renault and Nissan, Enevate now says its cells are ready for the big time. In an interview with Charged EVs, Park said Enevate is designing packs for the 2024 and 2025 model years to get its cells into consumer products with major manufacturers. There are no announcements around who or what exactly they're making packs for, but the list of companies above may be instructive.

As far as we're aware, though, the infrastructure to support blast-charging at the kinds of rates we're talking about here simply doesn't yet exist. Tesla's V3 superchargers are currently capable of blast-charging a Model 3 at 250 kilowatts, which would give you around 133 km (83 mi) of range in five minutes.

These batteries would charge three times faster, at around 0.75 megawatts, which is a huge power draw. An alternative method might involve trickle-charging massive supercapacitors all day at slower rates so they've got enough energy to supply the cars super-quickly when they need it, but we're yet to see anything like that in action, and the size of those supercapacitors might end up being prohibitive.

Still, there appear to be a number of potentially viable solutions crystallizing out of the vast amounts of battery research that is underway, and it seems clear that EVs will be jumping significantly both in range and charging speed in the next few years.

Source: Enevate via IEEE Spectrum