RheEnergise's HD Hydro 500 kW demonstrator will soon begin construction at mining company Sibelco's facility in Cornwood outside Plymouth in Devon, UK.

Hydroelectric power systems are the world's leading eco-friendly means of electricity production, accounting for 4,300 terawatt hours (TWh) of output or 15 percent of all electricity. Even though hydroelectrics have expanded in recent years, there's not much room for expansion – potential sites in practical locations are largely saturated.

That's because traditional hydro needs a large body of reliable water, with a high enough head for efficient electricity generation. If you live in the Pacific Northwest, you can run the entire region on hydroelectric, but if you're in Florida, you're a bit out of luck.

The same limitation is true for systems that store solar or wind energy by pumping water into reservoirs. If the system losses are reasonable, it's a sound idea, but not if you can't pump the water high enough, in large enough quantities.

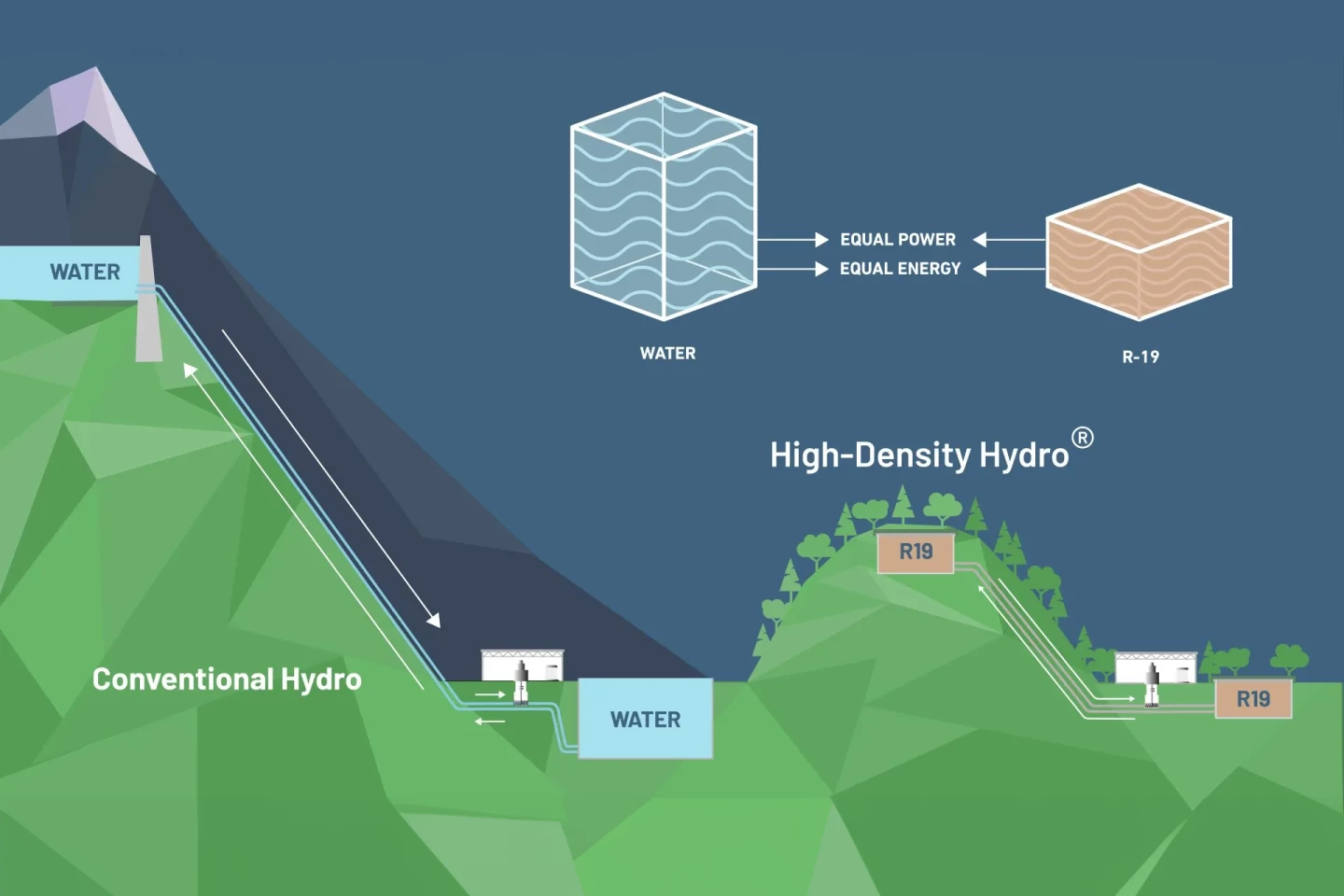

Britain's RheEnergise is trying to get around this by replacing the water with a fluid that is 2.5 times more dense than water. It doesn't exactly get rid of the H₂O, but it does mix it with a proprietary mineral powder called R19 that turns the water into a heavy, paste-like fluid.

With this heavier fluid, you can get the same energy storage performance as traditional pumped hydro, using 40% the volume, much smaller tanks, or 40% the height differential between the upper and lower tanks.

In this way, energy storage facilities can be set up in areas with much smaller hills – opening up this clean form of gravity battery to a huge range of locations worldwide that could never use it otherwise. According to the company, there are 6,500 potential sites in the UK alone.

RheEnergy also claims the cost comes in less than that of large-scale lithium-ion batteries. And on top of that, this kind of mechanical storage doesn't have the same leakage and degradation problems as batteries, so reserves can be kept for a matter of hours, days, weeks, months or years, depending on local needs.

All of the above makes this project huge news as the world shifts toward renewable energy grids in the race to decarbonization.

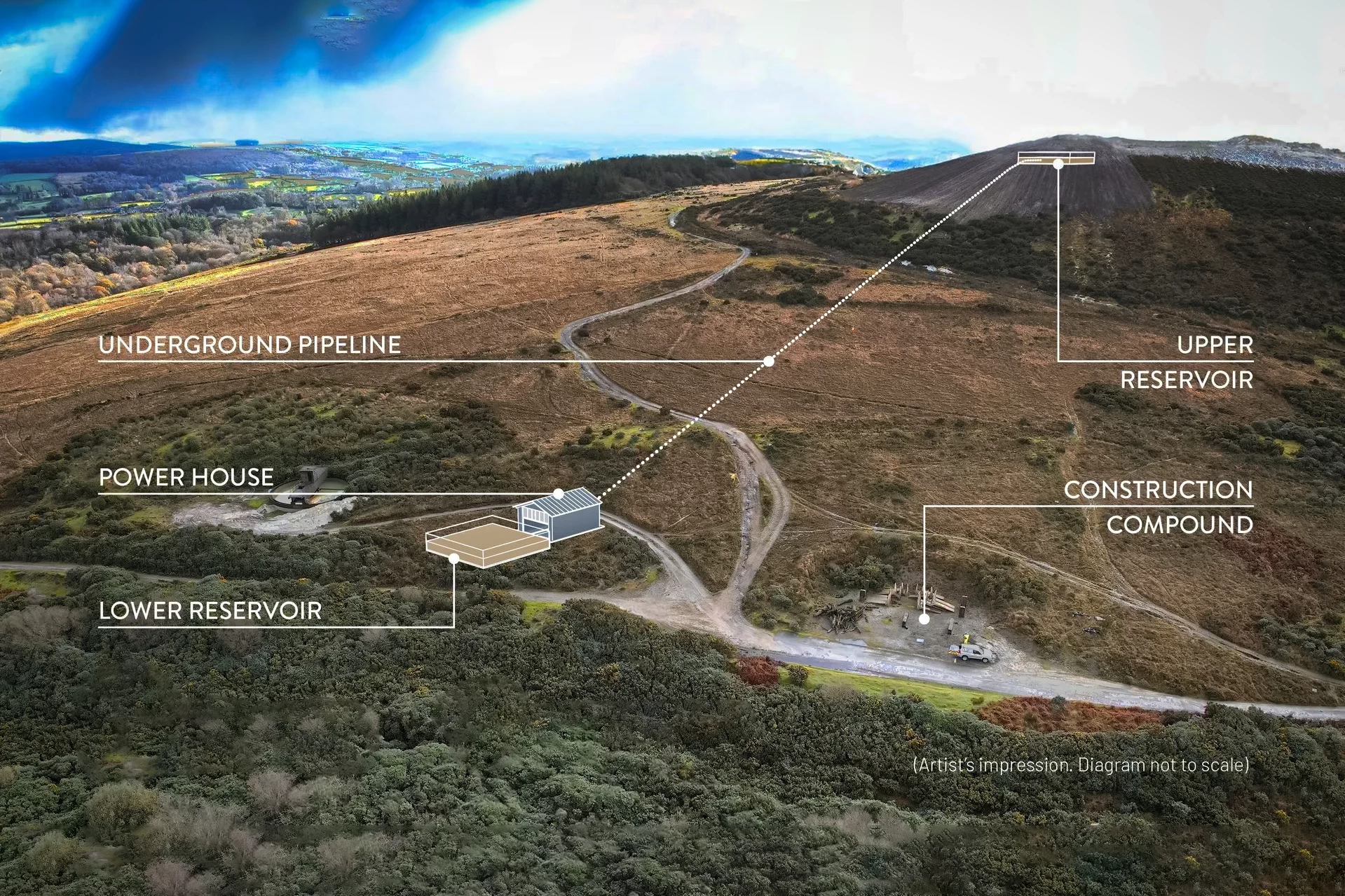

The new pilot facility is being installed at Sibelco's Cornwood site, which produces kaolin for sanitary ware (toilets to you and I), as well as ceramics, tiles, and industrial applications. The pilot plant is funded by the British Government’s Longer Duration Energy Storage (LoDES) Demonstration Programme – which seems an appropriate source of funding for a toilet manufacturer – and it has the support of Devon County Council.

If all goes to plan, this small pilot will soon be followed by much larger commercial projects. "The demonstrator is a trailblazing project for the LDES sector," says CEO Stephen Crosher in a press release, "and will place us in a strong position to build commercial-scale projects in this country and overseas. We have global interest in our technology, from as far as Australia and Chile. We would like to have our first 10MW grid-scale project in operation within 2 years."

Source: RheEnergise, via Recharge News