In an effort to find an efficient way to keep buildings cooler in hot weather and warmer in the colder months, researchers at University of Chicago’s Pritzker School of Molecular Engineering (PME) have developed a shape-shifting material that holds copper particles in either a liquid or solid form. Although the material uses a very low electric current to flip between the two states, it's a fraction of the energy it can save through passive heating and cooling.

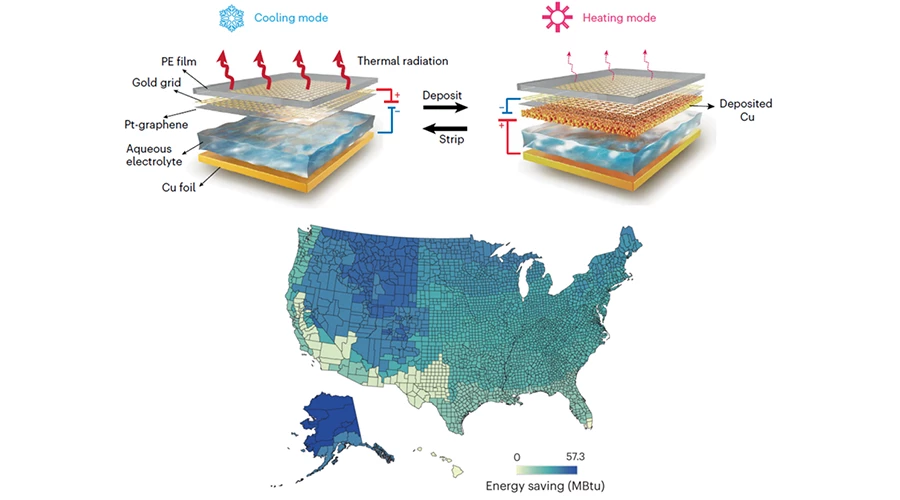

The non-flammable material consists of multiple layers including a polyurethane film, graphene sheet, and a gold grid. But the real action takes place thanks to an aqueous electrolyte and copper particles.

When the material is in heating mode, the copper particles are deposited onto the film, forming a solid layer that is excellent at absorbing solar heat. After a low electrical current is passed through the material, the particles disperse into the electrolyte and the material enters its cooling mode, where the warming infrared energy of the sun is reflected instead of absorbed. In the research, the material was successfully switched back and forth for 1,800 cycles.

“We’ve essentially figured out a low-energy way to treat a building like a person; you add a layer when you’re cold and take off a layer when you’re hot,” said lead researcher Asst. Prof. Po-Chun Hsu. “This kind of smart material lets us maintain the temperature in a building without huge amounts of energy.”

In fact, the researchers found that when the material is in the solid heating mode configuration, it can retain 93 percent of the infrared energy it comes in contact with. In the liquid cooling mode, it can reflect up to 92 percent of this energy. Even factoring the small electrical current needed to activate the shift, this translates into a savings of up 8.4% of the building's HVAC costs, say the researchers.

“Once you switch between states, you don’t need to apply any more energy to stay in either state,” said Hsu. “So for buildings where you don’t need to switch between these states very frequently, it’s really using a very negligible amount of electricity.”

What's more, the material can be programmed to change at any required temperature so it can essentially be tuned to work differently in different climates.

Plus, because the material is transparent when it's in its cooling mode, in addition to providing temperature-regulating benefits, it can also provide an interesting design element, as it would have a coppery appearance when in solid heat-retaining mode, but could show any pigment applied to a bottom layer when in transparent cooling mode.

Materials that change color this way in response to an electrical current are known as electrochromic and we've seen a very similar material developed two years ago from scientists at North Carolina's Duke University. We've also seen such materials developed for use in window films and sunglasses.

As of now, the researchers have created pieces of the material measuring approximately 6 cm (about 2.4 in) across but, they say, it might be possible to build up coverage by using it in a shingle-like configuration. Their next steps are investigating ways in which to fabricate the material and looking at how using the material between its liquid and solid states might also be valuable in terms of passive thermal control.

The research has been published in the journal Nature Sustainability.

Source: University of Chicago