Farmers around the world regularly burn post-harvest crop waste, producing a significant amount of greenhouse gases and air pollution in the process. A new portable system, however, can be brought to farms to convert that waste into useful products.

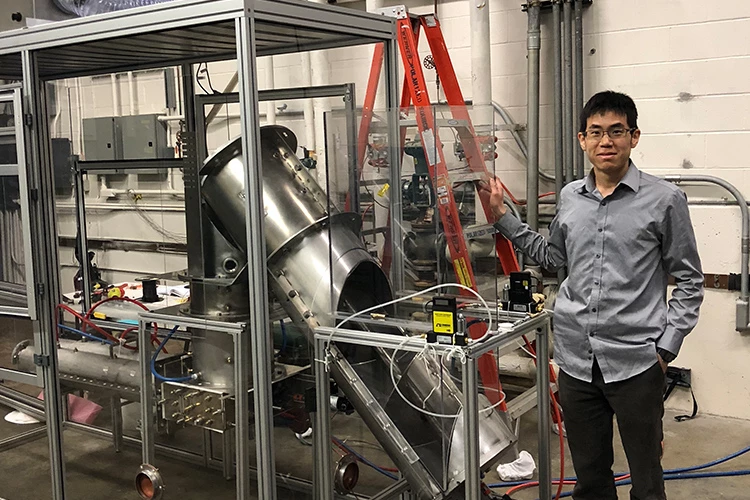

The technology is the brainchild of Kevin Kung, who is currently a post-doctoral researcher in the Biomass and Bioenergy Research Group at Canada's University of British Columbia. It's being developed by spinoff company Takachar, of which he is the Chief Technical Officer.

The system is compact enough to be towed to farms by a tractor or pickup truck, for onsite small-scale conversion of biomass waste into products such as fertilizer, solid fuel and other speciality chemicals.

Its portability is an important factor, as farmers would otherwise be responsible for transporting their waste to a central refinery ... a task which they might not have the time or inclination to do. The technology is also capable of processing forestry waste, so it could likewise make trips to logging sites.

The exact means by which the system works is a bit of a trade secret, although Kung did tell us, "This is a thermochemical process whereby we treat biomass under moderate heat to drive out low-energy molecules, resulting in higher-grade, carbon-based bioproducts."

He added that in the current business model, Takachar buys biomass waste from farmers and then sells the resulting fertilizer back to the community. That may change as the system enters wider use, however. As part of an ongoing pilot project, six units are currently in use in North America and India.

"Current technologies for turning biomass into usable products are large-scale and centralized, which means they only work well if the source is nearby," said Kung. "Our Aha! moment came when we realized we could circumvent the logistics issue by bringing the technology to the field or forest instead."

Kung was recently the recipient of an award and $5,000 of development funds from Mitacs, a government-funded non-profit organization that seeks to foster technical innovation in Canada. Past recipients have developed technologies such as a computer-vision-based flight recorder, an augmented reality feedback system for athletes and a screw-drive amphibious robot.