Most robotic grippers work by applying pressure to an object from either side – it's an approach which could damage delicate items. A new gripper gets around that problem, however, thanks to an ancient Japanese art form.

Related to the paper-folding art of origami, kirigami involves making a series of parallel slits in a flat sheet of material.

When that two-dimensional sheet is subsequently pulled apart, pushed inwards, twisted or otherwise manipulated, the slits cause it to buckle into a predetermined three-dimensional shape. In recent years, we've seen the art form utilized in everything from programmable balloons to robotic snakes to anti-slip shoe soles.

The 3D shape which a kirigami sheet takes on is determined not only by the slit patterns and the way in which it's manipulated, but also by the shape of the flat sheet. A disc-shaped sheet, for instance, will typically morph into a sphere.

Led by PhD student Yaoye Hong and Assoc. Prof. Jie Yin, a team at North Carolina State University has now developed a computer program that figures out what sheet shape, slit pattern and type of manipulation is required in order to end up with a specified 3D shape.

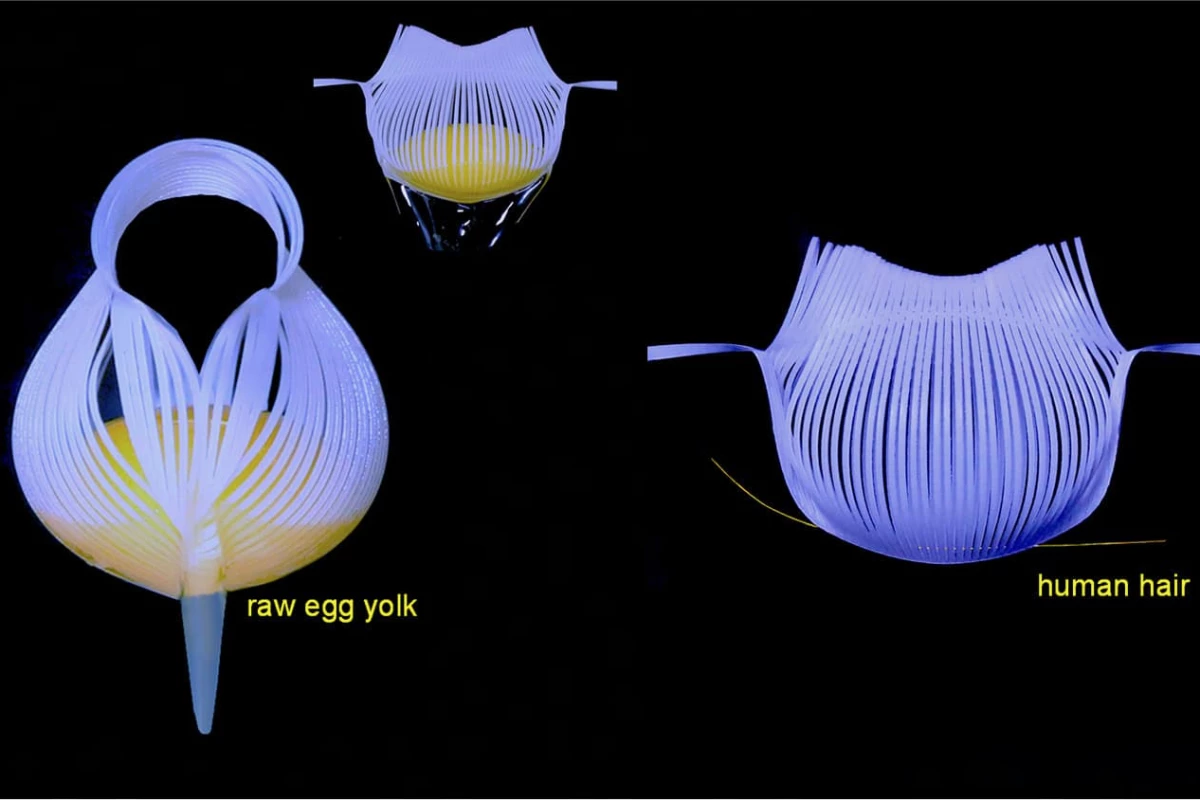

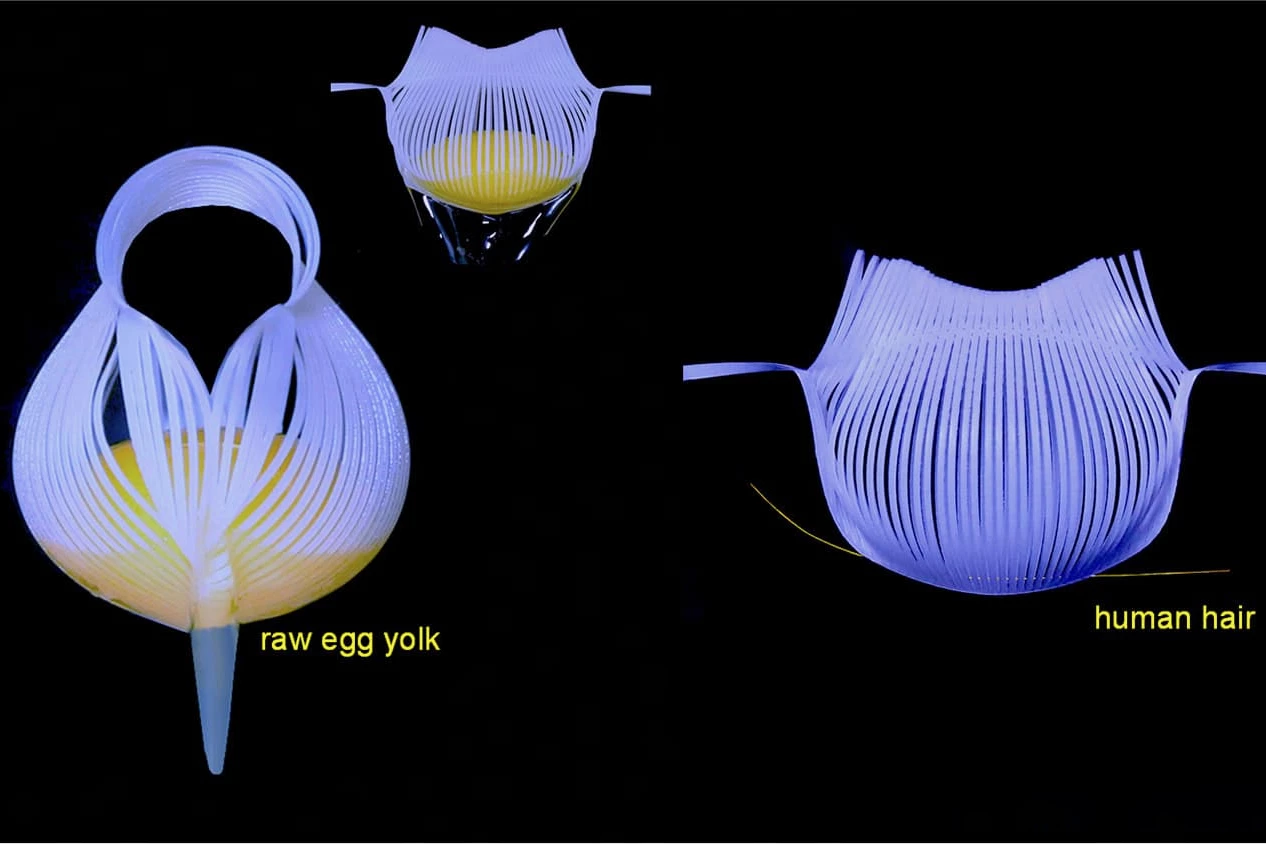

The scientists used the technology to create a flexible robotic gripper, the two sides of which slide together beneath a fragile object, meeting on its underside and surrounding it like a pair of cupped hands. Not only is the device gentle enough to lift an egg yolk without breaking it, but it's also precise enough to grasp and lift a human hair.

"This is proof-of-concept work that shows our technique works," said Yin. "We’re now in the process of integrating this technique into soft robotics technologies to address industrial challenges."

A paper on the research was recently published in the journal Nature Communications. The gripper is demonstrated in the following video.

Source: North Carolina State University