People may joke about tight jeans being "spray-on pants," but Swiss brand On's new Cloudboom Strike LS is a spray-on running shoe … sort of. Its LightSpray production process is said to be much faster and greener than traditional methods, resulting in an ultra-lightweight finished product.

The single-step LightSpray technique was inspired by an online video which showed how to create Halloween spider web decorations using strings of glue from a hot glue gun. It's used to produce the shoe's ultra-thin, one-piece upper.

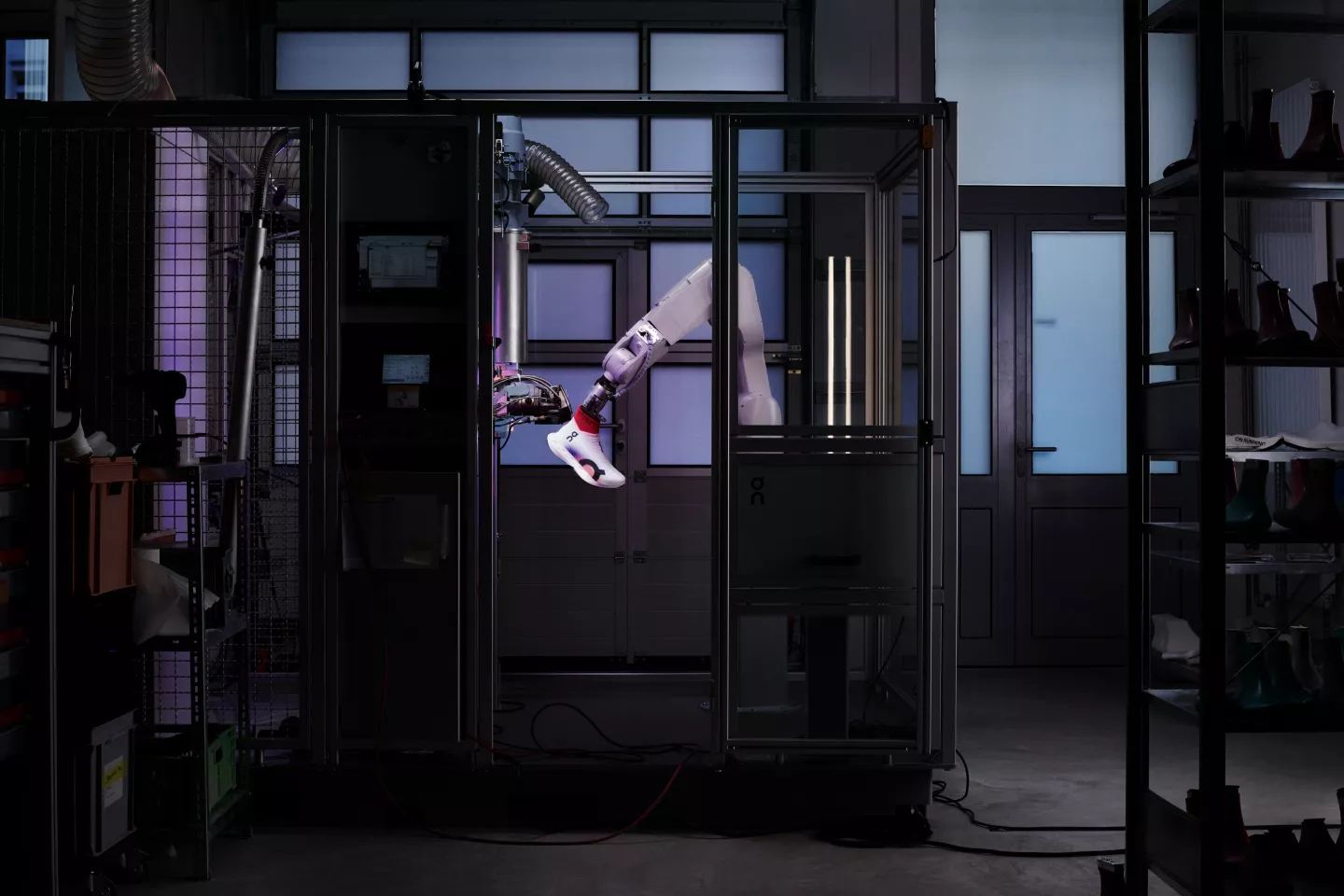

At the heart of the setup is a three-dimensional foot form model. It already has the shoe's sole on the bottom, and is attached to a robotic arm at the top. That arm precisely tilts and rotates the form next to a nozzle, which steadily sprays filamentous thermoplastic onto the sides of the form.

Once it has set, the continuous ribbon of sprayed-on material constitutes the shoe's laceless, flexible, stretchable upper. It's bonded to the midsole via a glue-free thermal fusing technique. The whole LightSpray process, from putting the form on the arm to pulling the shoe off the form, takes just three minutes to assemble one shoe. Keep in mind, though, the sole is pre-manufactured in a more traditional manner.

According to On, LightSpray produces far less waste than conventional upper-manufacturing techniques, since the only material that's expended goes into the upper. No glue, stitching, or cutting off of excess material is required. Additionally, the quick and efficient process is claimed to produce 75% fewer carbon emissions than the traditional techniques used in the production of On's other shoes.

What's more, because the production space is so small and relatively simple, shoes could be assembled in numerous geographical locations, minimizing transportation-related CO2 emissions. For now, though, all of the shoes are being produced at the On Labs facility in Zurich.

Using a men's 8.5-US-size shoe as an example, each upper weighs just 30 grams (1 oz), with the whole shoe reportedly tipping the scales at 170 g (6 oz).

Limited numbers of the Cloudboom Strike LS were initially made available to the public in April, with more set to follow this fall (Northern Hemisphere). Should you want a pair, it'll set you back US$330.

The LightSpray system can be seen in action, in the video below. And for a previous example of On's eco-minded thinking, check out its Cloudprime running shoes, the midsoles of which incorporate captured carbon monoxide gas emissions.

Source: On