In order to keep ice from forming on surfaces such as airplane wings, toxic chemicals are typically applied. And while there are experimental chemical-free alternatives, they still require a power source or involve coatings that can wear off. A new system, however, gets around those issues.

Developed by a team at Virginia Tech, the technology doesn't keep surfaces completely ice-free, but it drastically reduces the area that is ice-covered.

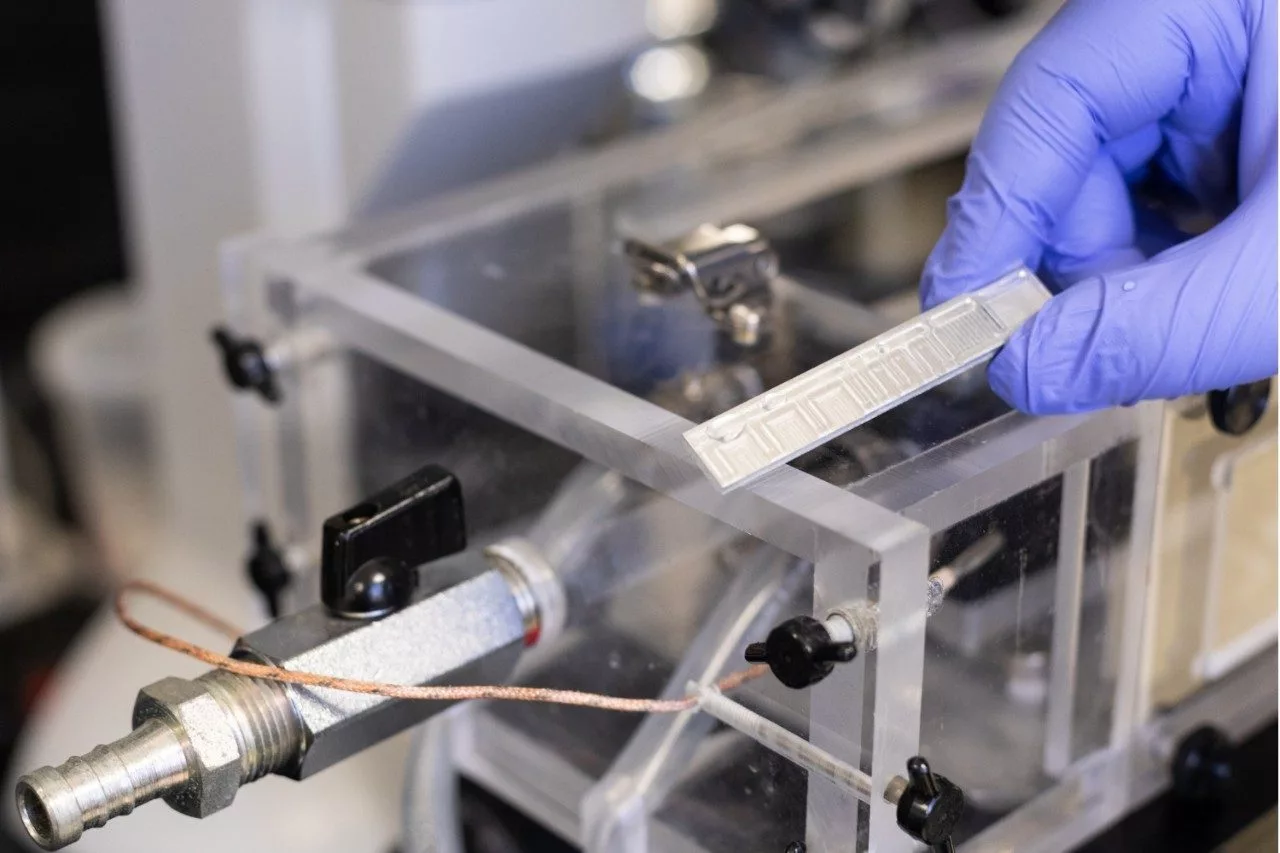

It centers around microscopic arrays of elevated grooves that could conceivably be etched into the surface of materials such as the aluminum used to build an airplane wing, or the glass for a car's windshield. In cold, wet environments, water wicks into these grooves and freezes into stripes of ice, which cover about 10 percent of the surface.

"These ice stripes siphon all nearby moisture from the air, preventing any condensation or frost from growing on the intermediate portions of the surface (the other 90 percent)," assistant professor Jonathan Boreyko tells us. "This is because ice is a low-pressure chemical, analogous to salts."

The problems with simply using salt, he adds, is that it gets diluted as it draws in more water, plus it's environmentally unfriendly once it gets washed off of the surface. By contrast, the ice in the micro-grooves simply becomes more ice as it attracts moisture. That said, it grows at a much slower rate than it would if it were forming a single continuous sheet.

So far, the system has been successfully tested on ordinary aluminum (seen above). It could reportedly be used on just about any material, however, as long as the grooves were applied in the correct pattern.

A paper on the research was recently published in the journal ACS Applied Materials and Interfaces.

Source: Virginia Tech