As ships travel the seas, an assortment of barnacles, mussels, algae and other greeblies accumulate on their hulls. This is definitely troublesome, which is why a new robot-based system has been developed as a possible solution.

The growth of marine organisms on ship hulls is known as biofouling, and it poses a couple of key problems.

First and foremost, by adding a rough living coating to the hull, it keeps ships from smoothly cutting through the water. This means that their engines have to work harder in order to maintain a given speed, thus using more fuel and producing more exhaust. Additionally, the introduction of invasive, non-native species may occur if organisms latch on in one geographical location and then reproduce in another.

With these issues in mind, Norwegian company Jotun has collaborated with Swedish tech firm Semcon – along with other partners – to develop its Hull Skating Solutions system.

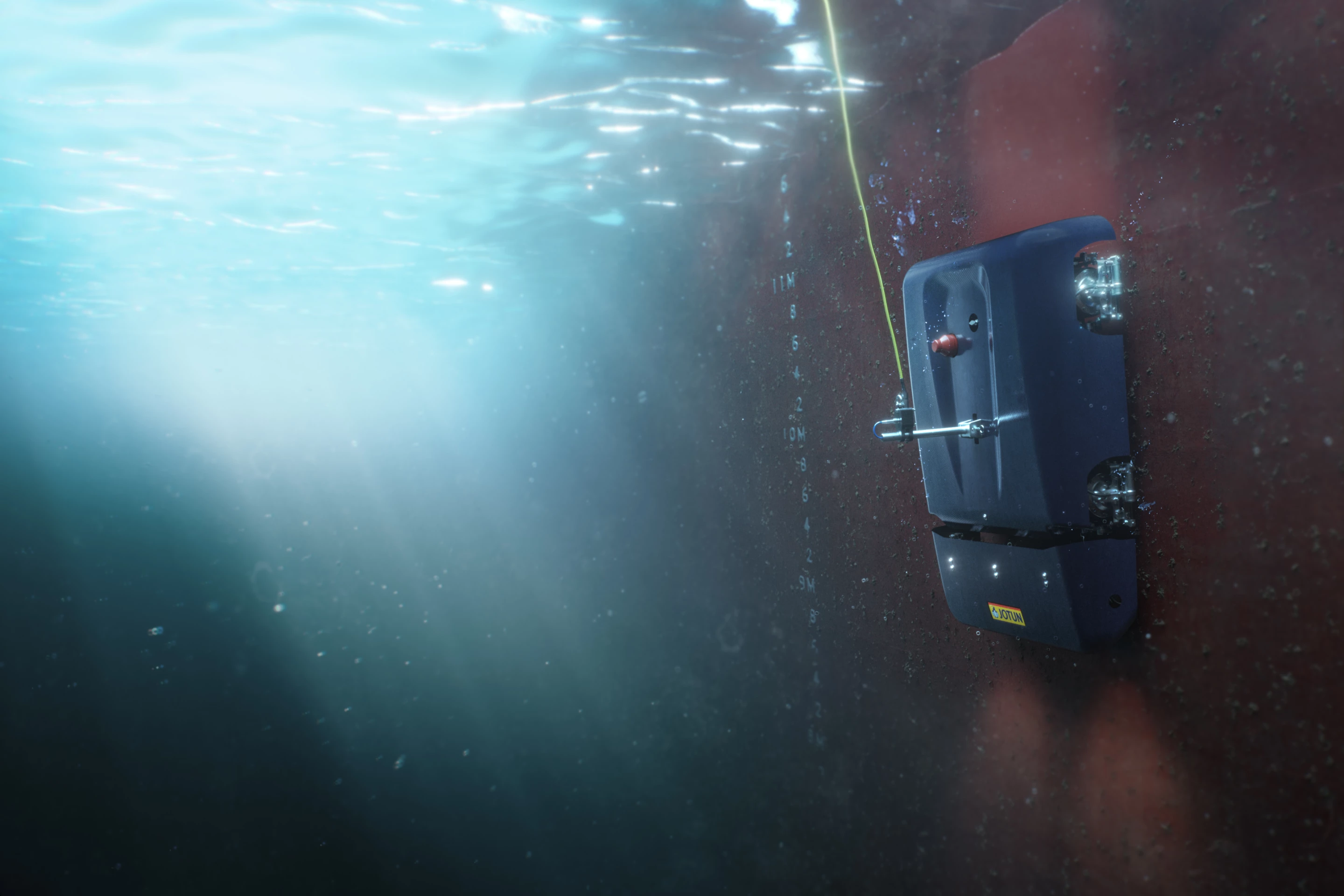

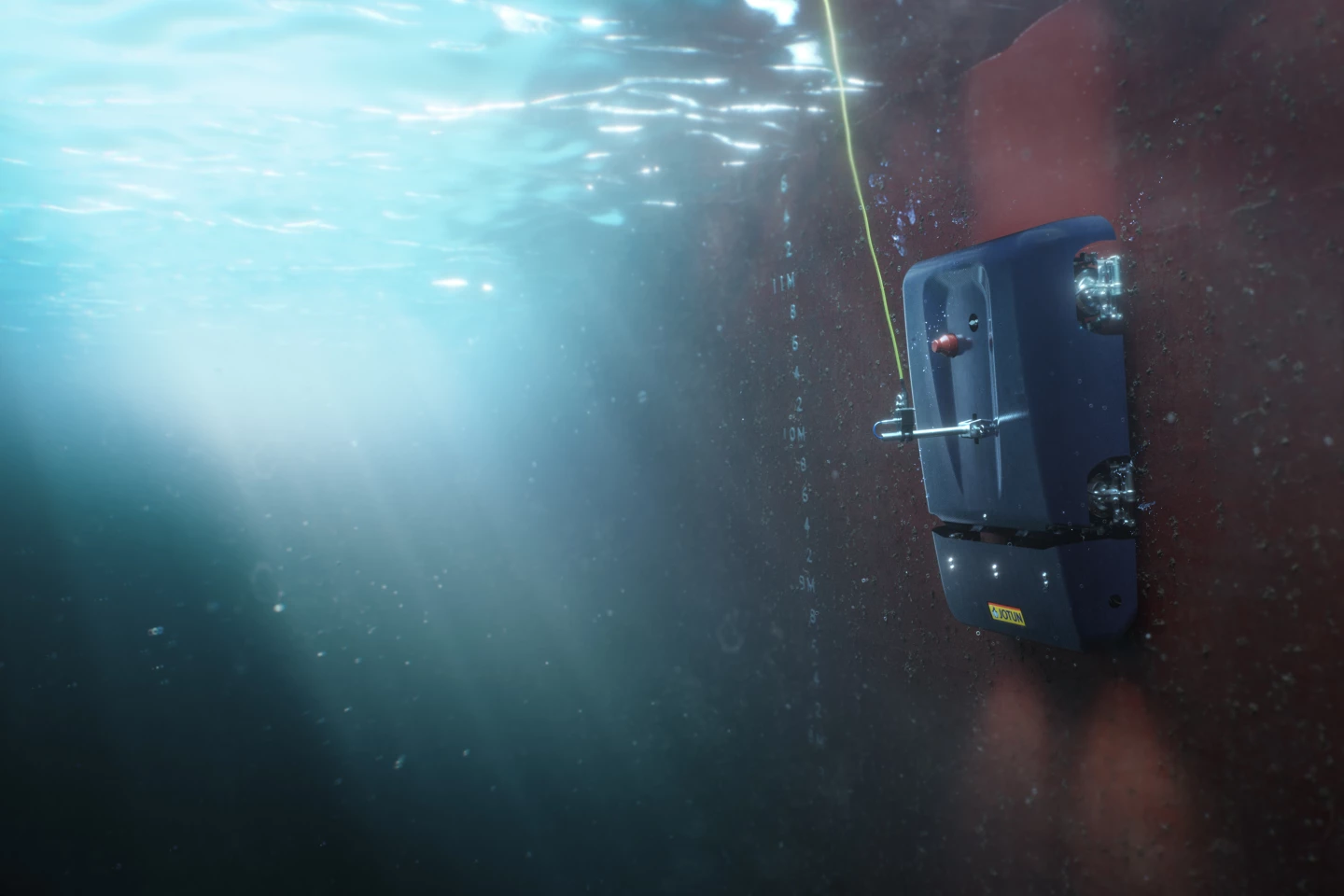

It begins with the proprietary SeaQuantum Skate silyl acrylate-based coating being applied to the ship's hull. While this resists biofouling all on its own, it's also designed to not be damaged by the HullSkater robot, which is the system's other main component.

That robot stays aboard the ship full-time, in a portable station that includes a launch and recovery ramp. An internet-based system – which monitors the ship's status and location, along with marine conditions – lets the crew know when hull-cleanings should be performed. The ship has to be anchored or docked at the time.

Once launched, the HullSkater clings to the underside of the vessel using its four magnetized wheels. Motors in each of those wheels proceed to move it along, while a rotating brush on its front end preemptively scours away the "biofilm" that forms in advance of outright biofouling.

The robot isn't autonomous, but is instead remotely piloted in real time by Jotun staff located in a 24-hour operations center. They're guided by output from the HullSkater's four spotlight-assisted cameras (three front, one rear) – that data is carried from the bot to a 4G transceiver on the ship, via an umbilical cable. One complete cleaning should take two to eight hours, depending on the vessel.

The system is now being field-tested on ships, with a commercial rollout planned to follow. It can be seen in action, in the video below.

Florida-based SeaRobotics, by the way, has also commercialized a semi-autonomous hull-cleaning robot.