Playing an indispensable role in global construction, cement contributes around seven percent of annual greenhouse gas emissions owing to its carbon-intensive production process. Scientists at the University of Colorado Boulder claim to have uncovered a greener path forward by tapping into a species of cloudy microalgae, which naturally produce limestone particles through photosynthesis and could turn buildings into carbon sinks as a result.

Limestone is a key ingredient in cement, but adding it to the mix is incredibly energy intensive. It first needs to be extracted from the earth, then crushed up, baked at extremely high temperatures and treated, which involves burning huge amounts of fossil fuels and also releases stored carbon as a result. Scientists have made promising advances toward more sustainable methods by substituting limestone for discarded clay or volcanic rock, but the latest advance comes about through a snorkeling trip to Thailand in 2017.

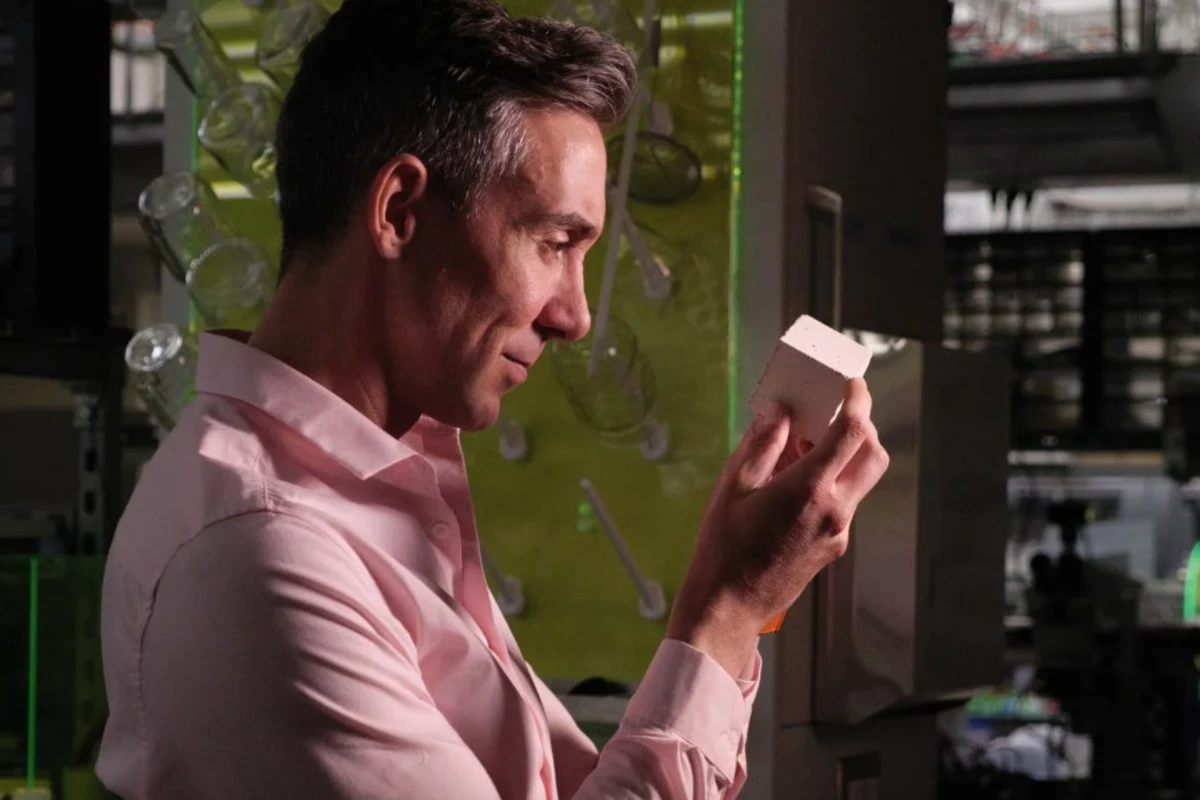

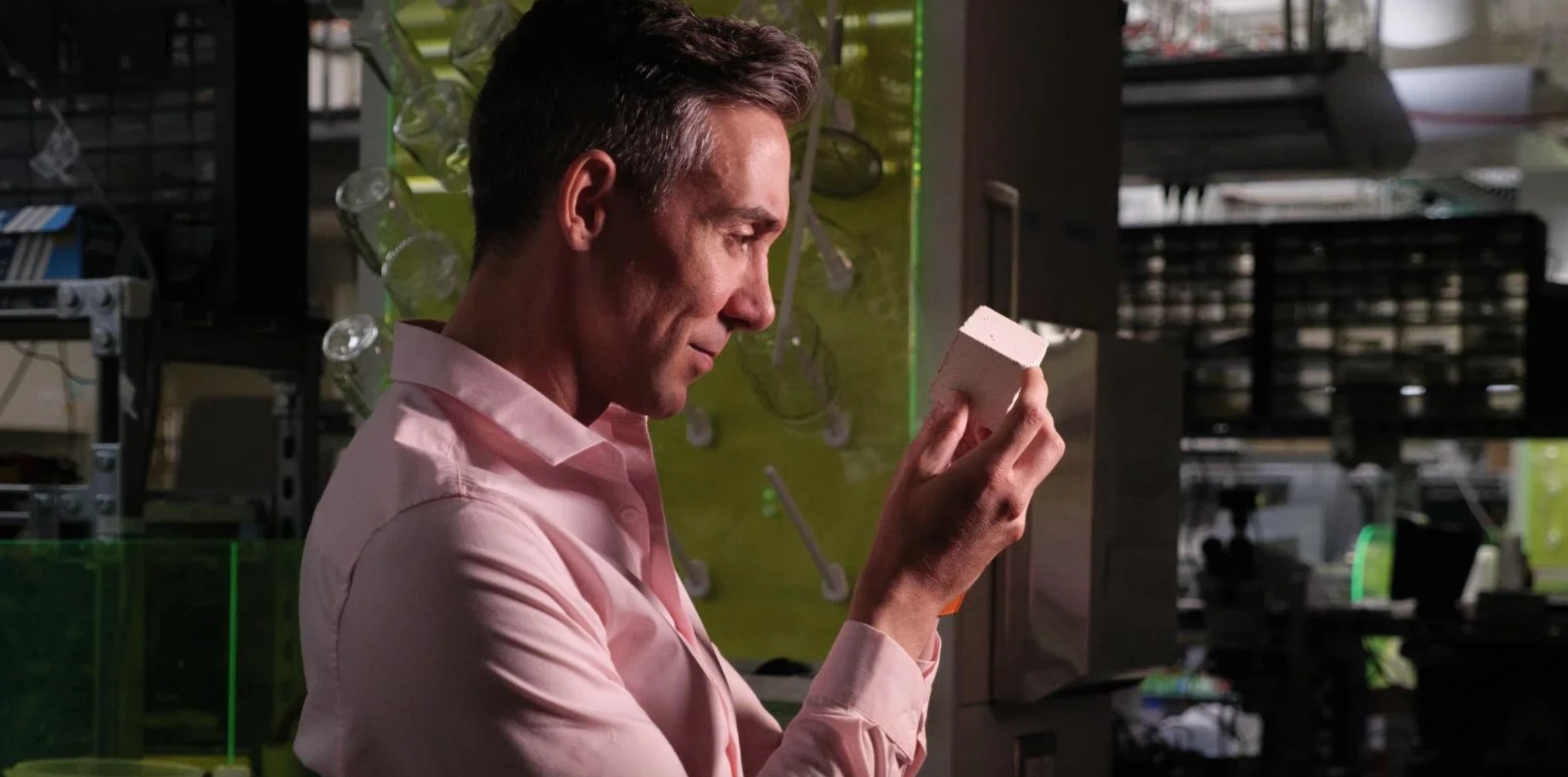

Material scientist Wil Srubar was visiting coral reefs in the area and drew inspiration from the way the structures are naturally formed by calcium carbonate, a key component of limestone. He wondered if this natural process could be leveraged to produce the material in a more environmentally friendly manner, which led him and his team to a form of microalgae called coccolithophores.

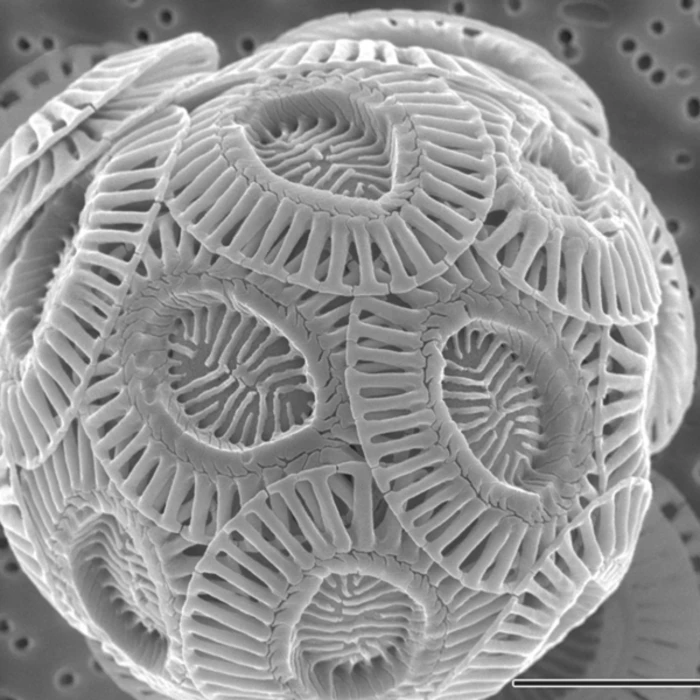

These tiny creatures naturally sequester and store carbon dioxide through photosynthesis, using sunlight and seawater to turn it into calcium carbonate at a faster rate than coral reefs. They also live in warm water, cold water, saltwater and freshwater, which bodes well for the potential to cultivate them around the globe.

“On the surface, they create these very intricate, beautiful calcium carbonate shells," said Srubar. "It's basically an armor of limestone that surrounds the cells.”

The team used the coccolithophores to produce biologically grown limestone, which was used as a substitute for quarried limestone to create concrete with a far lower environmental footprint. Srubar says these "look, feel and behave exactly like concrete," but the cement used to create it is net carbon neutral or even carbon negative, in that the associated carbon dioxide emissions are less than what is captured by the microalgae.

“This is a really exciting moment for our team,” said Srubar. “For the industry, now is the time to solve this very wicked problem. We believe that we have one of the best solutions, if not the best solution, for the cement and concrete industry to address its carbon problem.”

Srubar and his team have just been awarded a US$3.2-million grant from the US Department of Energy to continue developing the technique, and look at ways of scaling up production of biogenic-limestone-based cement.

The scientists calculate that between 1-2 million acres of open ponds would be needed to cultivate enough microalgae to meet the cement demands of the US, which they note is just one percent of the land used to grow corn. Applied globally, they say the technique could mitigate two billion gigatons of carbon dioxide emissions each year. Perhaps most promisingly, the biogenic limestone is described as "plug and play" with current cement production processes, and could theoretically be implemented as quickly as overnight.

“We see a world in which using concrete as we know it is a mechanism to heal the planet,” said Srubar. “We have the tools and the technology to do this today.”

You can hear from Srubar in the video below.

Source: University of Colorado Boulder