While we may think of wood as being earthy and natural, wooden materials such as plywood and particleboard typically contain formaldehyde-based adhesives that give off toxic fumes. Such is not the case with a new adhesive, however, which is made from glucose and citric acid.

The substance is being developed by a team of scientists from China's Southwest Forestry University.

They're building upon previous research, which showed that a water-resistant wood glue could be made from sucrose – which consists of glucose and fructose sugars – along with citric acid derived from citrus fruits. In order to reduce the amount of energy required for the curing process, a zinc chloride catalyst had to be added to that glue. Unfortunately, doing so reduced the strength of the adhesive.

Seeking to address this shortcoming, the scientists experimented with combining straight glucose and citric acid in various ratios, producing a "sticky liquid" which they applied to the surface of poplar veneers. Three veneers were sandwiched together in this fashion, then pressed at a temperature of 392 ºF (200 ºC) for six minutes.

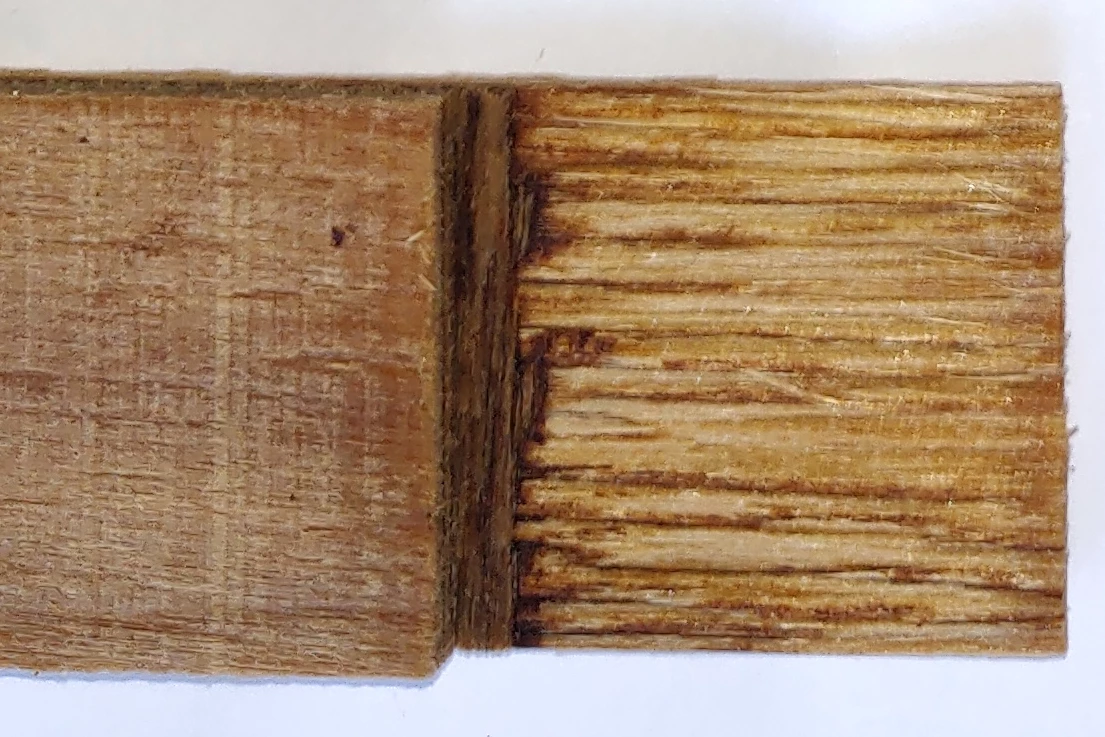

The resulting single laminated sheet of plywood was then cut into smaller pieces, which were subjected to strength testing. Those tests showed that under load pressures of over 101 psi (7 bar), the samples broke along the grain of the wood fibers, not at the glued seams – this met the Chinese strength requirement for plywood.

When soaked in boiling water, some of the samples failed to meet water-resistance standards. The ones that did meet those standards incorporated versions of the adhesive that a particularly high citric-acid-to-glucose ratio. It is believed that this outcome may have been due to an increase in molecular bonding between the citric acid and the wood.

A paper on the research was recently published in the journal ACS Applied Materials & Interfaces.

Source: American Chemical Society via EurekAlert