A new method for recovering high-purity gold from discarded electronics is paying back US$50 for every dollar spent, according to researchers – who found the key gold-filtering substance in cheesemaking, of all places.

Society has held gold in high esteem for millennia. More recently, for its technical applications across electronics and microelectronics, aerospace, medicine, biotechnology, and nanotechnology. However, like any metal, gold is a non-renewable resource. And increasingly valuable.

In a new study, researchers from ETH Zurich, Switzerland, have detailed a sustainable, cost-effective method of selectively extracting gold from electronic waste or e-waste.

“The fact I love the most is that we’re using a food industry byproduct to obtain gold from electronic waste,” said Raffaele Mezzenga, the study’s corresponding author. “You can’t get more sustainable than that!”

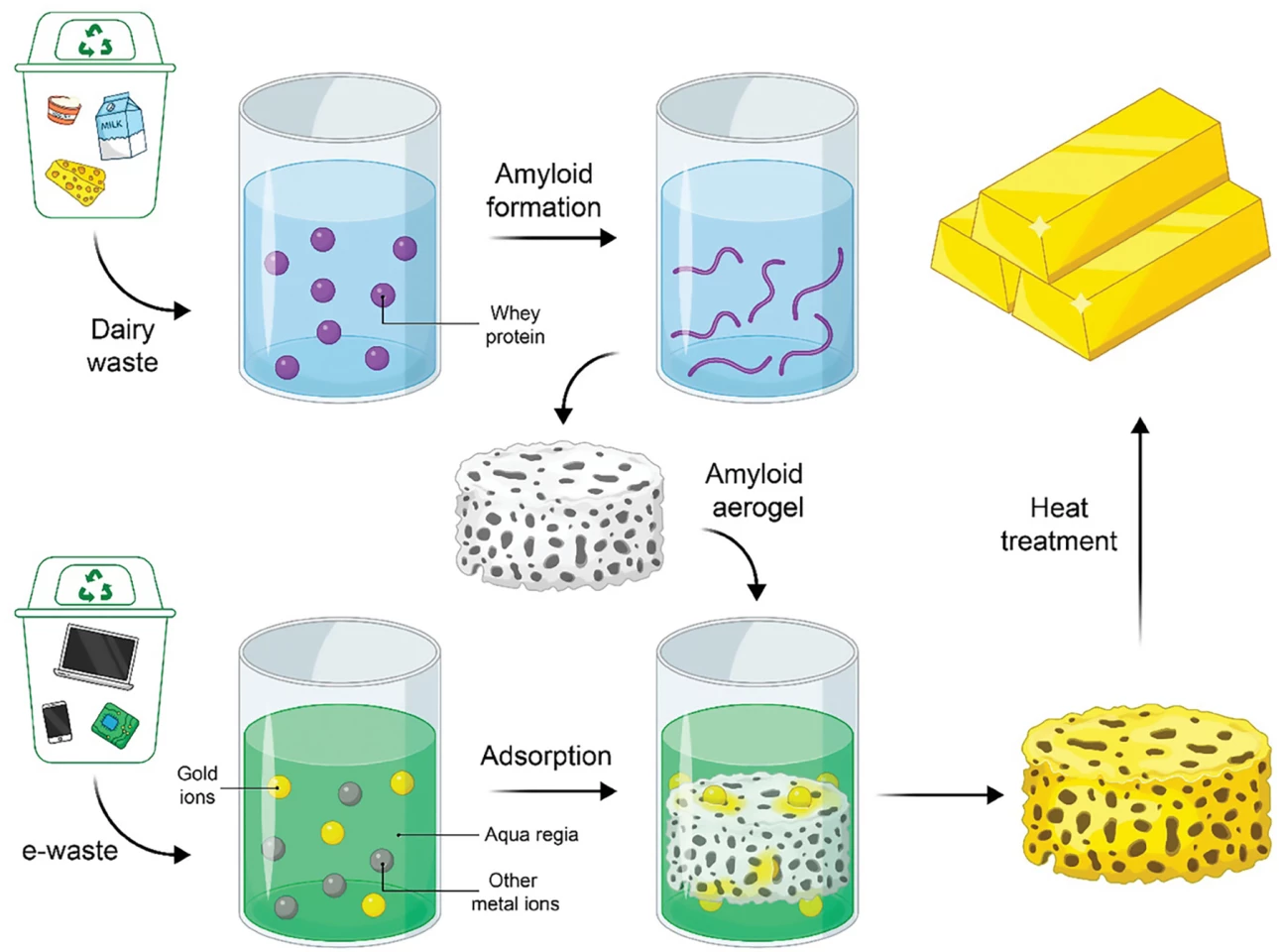

The food industry byproduct Mezzanga is referring to is whey, the watery portion of milk that separates from the curds when making cheese. Here, the researchers turned this dairy waste into a matrix of protein amyloid fibrils they used as an adsorbent to selectively remove gold from e-waste.

Under acidic conditions and high temperatures, the whey proteins were denatured – the destruction of the protein’s structure into a looser, more random one – causing them to aggregate into nanofibrils in a gel. The gel was dried and formed into a sponge.

The researchers extracted the metal parts from 20 old computer motherboards and dissolved them in an acid bath to ionize the metals or separate them into positive and negative ions. When the protein fibril sponge was placed in the metal ion solution, the gold ions stuck to it. While other metals – copper and iron, for example – were also absorbed by the sponge, gold was absorbed far more efficiently.

After absorbing the gold ions, the protein fibril sponge was subjected to heat, reducing the ions to flakes which eventually melted down into a gold nugget with a mass of around 500 mg. Analysis revealed that the nugget was made predominantly of gold (90.8 wt%), with copper and nickel contributing 10.9 wt% and 0.018 wt%, respectively. The findings demonstrate the high purity of the nugget, corresponding to 21 or 22 karats.

In their paper, the researchers demonstrated their method’s commercial viability. Including both source material procurement costs and the energy costs for the entire process, the total cost of recovering 1 g of gold from e-waste was 50 times lower than the value of the gold recovered.

And the method is better from an environmental standpoint. Using conventional activated carbon to recover 1 g of gold from e-waste would produce around 116 g of carbon dioxide, whereas the protein fibril sponge’s carbon footprint is lower, resulting in approximately 87 g of the greenhouse gas. The main reason for the higher environmental impact of using activated carbon is its higher energy consumption during production, predominantly due to non-renewable fuel sources, coupled with a lower adsorption capacity than the sponge.

Previous attempts to extract gold have all had their drawbacks, such as scalability.

Because whey is an animal-based protein, the protein fibril sponge will likely cause more ecosystem damage than activated carbon. As such, the researchers will explore whether plant-based proteins, such as those derived from peas and potatoes, can be used instead of whey.

The researchers plan to ready the technology for the market. While e-waste is a promising starting source to extract gold, they are eyeing others, including industrial waste from microchip manufacturing or gold-plating processes.

The study was published in the journal Advanced Materials.

Source: ETH Zurich