Engineers at Michigan State University (MSU) have crafted a new type of liquid foam lining they say can help football helmets better sustain repeated impacts, improving their longevity and the safety of those wearing them. The material would also be thinner and less bulky than the foam liners currently used, and could find use as a safety device in other areas such as automotive manufacturing.

The foam lining of a football helmet sits inside the harder polycarbonate exterior and plays an important role in absorbing energy from impacts to protect the wearer’s head. But severe forces can compromise this important safety element, which means that it needs replacing or can pose a serious safety threat if the damage goes unnoticed in the heat of battle.

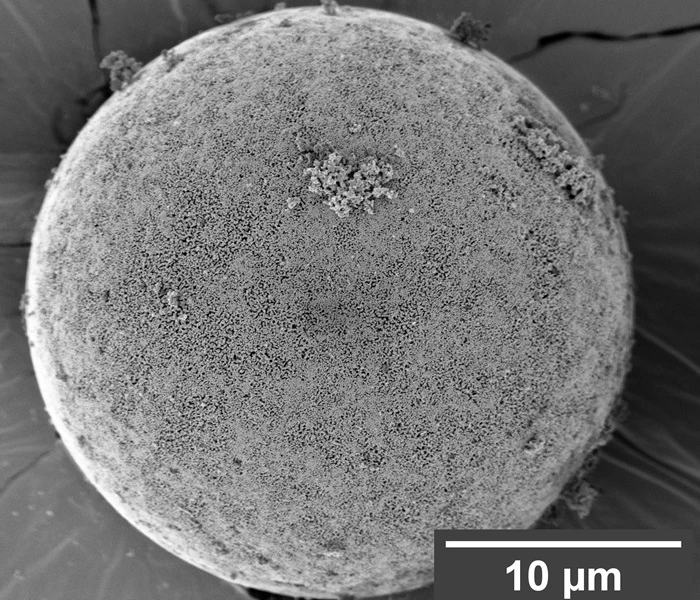

The MSU team has been exploring alternatives to the solid foams used today, and believes it has landed on a winning recipe. Its liquid nanofoam is packed with tiny pores just nanometers in size, which create a huge surface across a small amount of material.

“The whole area of MSU’s Spartan Stadium could be folded up into one gram of nanofoam,” says lead researcher Weiyi Lu.

The foam is coated with water repellent silicone to prevent moisture from entering and filling the pores, while also sealing away saltwater inside. When the foam receives a blow, this internal solution becomes pressurized and flows into the available space, making the material pliable and able to absorb impacts.

“When the pressure reaches the safety threshold, ions and water are forced into the nanopores making the material deformable for effective protection,” explains Lu. “In addition, the liquid-like material is pliable enough to form into any shape. Helmets are pretty much one shape but the liquid nanofoam material can be made to fit a person’s specific head shape or profile."

In testing, the performance of an eight-inch liquid foam liner was compared to a conventional three-quarter-inch solid foam liner. Both materials were impacted with a mass simulating another human head at a speed of three meters per second, and both were deformed as a result. But unlike the conventional foam, the liquid nanofoam was able deform but then recover to take more blows.

“The liquid nanofoam outperformed the solid foam,” Lu said. “The nanofoam was able to mitigate continuous multiple impacts without damage; the results were identical from test one through test 10.”

In addition to football helmets, the team sees its new foam finding use in military gear, more earthquake-resistant structures and the automotive industry, where it could serve in advanced air bags and bumpers. The team is now planning further studies to test its performance against more intense impacts, such as that of a bomb blast.

"We want this material to help not just extend people's lives but to improve their quality of life,” Lu says.

The research was published in the Proceedings of the National Academy of Sciences.

Source: Michigan State University