Though you can make objects smarter by adding sensors to them, a team of MIT engineers has managed to 3D print metamaterial structures with electrodes directly integrated into them to allow objects to sense user interaction.

The repeating structures of metamaterials help determine their properties and functions, rather than what they're made from, and by tweaking the designs, we've seen engineers pull off the seemingly impossible – such as creating an ultra-wide fisheye lens that's flat instead of bulbous, structures that help levitate objects with sound, and others that can make things invisible to sensors.

"Metamaterials can support different mechanical functionalities," says co-lead author of a paper on the new development, Jun Gong. "But if we create a metamaterial door handle, can we also know that the door handle is being rotated, and if so, by how many degrees? If you have special sensing requirements, our work enables you to customize a mechanism to meet your needs."

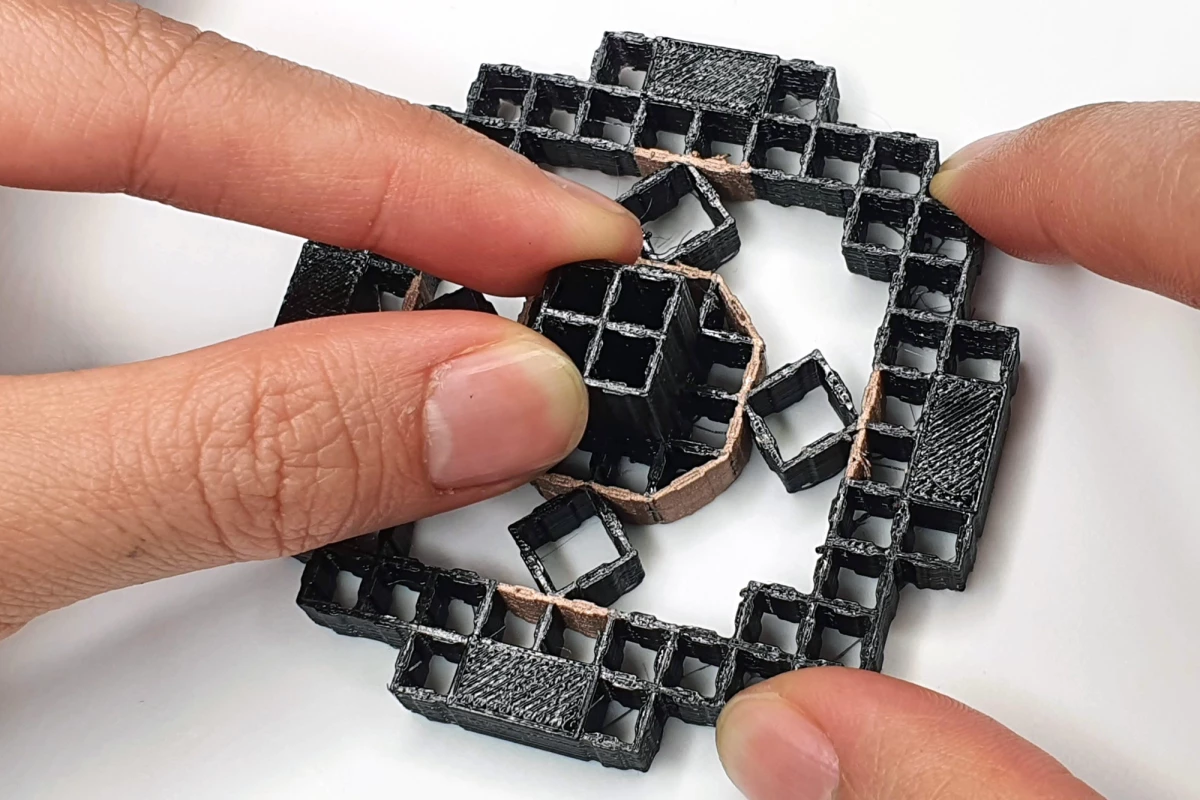

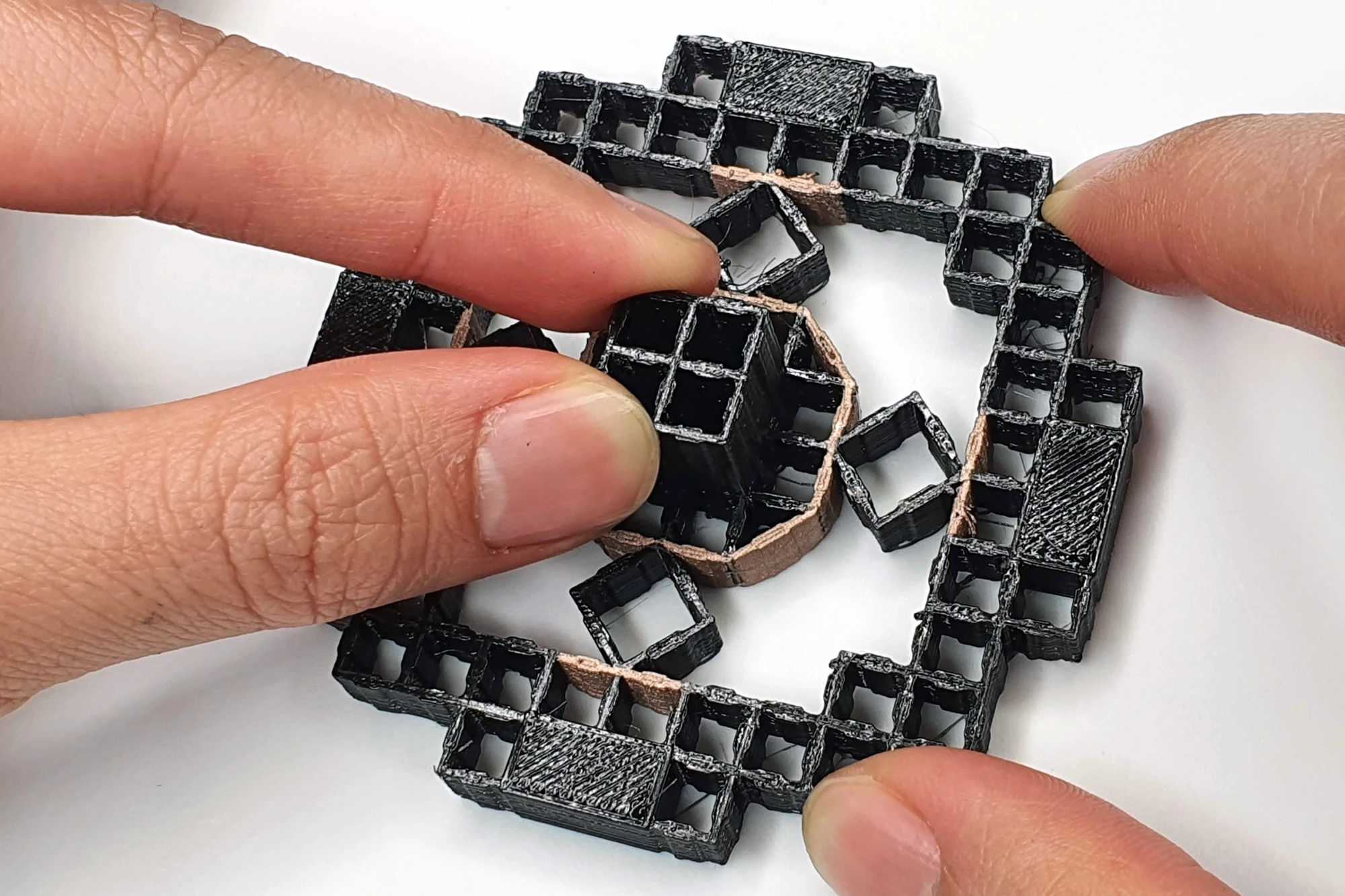

Noting that as force is applied to a metamaterial structure some of the cell walls will flex, the engineers 3D printed a metamaterial joystick made up of flexible cells. Most of the cells were printed using non-conductive filament, but those around the base of the handle had opposing walls made of conductive filament in a configuration called conductive shear cells.

Employing capacitive sensing, changes in the distance and overlap between the opposing conductive electrodes can be measured to "calculate the magnitude and direction of the applied forces, as well as rotation and acceleration." These values were subsequently converted into up/down/left/right inputs for a Pac-Man game, as you can see in the video below (along with other applications such as weighing scales, a handheld music controller for a digital synth, and even an accelerometer).

The team also developed software called MetaSense that could allow designers to create sensing objects, automatically determining the optimum locations within a simulated metamaterial structure for the placement of conductive cells.

"The tool will simulate how the object will be deformed when different forces are applied, and then use this simulated deformation to calculate which cells have the maximum distance change," says Gong, who was a visiting PhD student at MIT during the project, but now works as a research scientist for Apple. "The cells that change the most are the optimal candidates to be conductive shear cells."

The researchers see the development leading to such things as furniture incorporating metamaterials that could, for example, detect when a user sits down and trigger the room lights to switch on or turn on the TV, or be used to detect body posture and make corrective suggestions. Next steps include building larger sensing mechanisms incorporating thousands of conductive shear cells and improving the algorithms in the software for better simulations.

The project is scheduled to be presented at next month's Association for Computing Machinery Symposium on User Interface Software and Technology. A paper on the research penned by Gong, Olivia Seow, Cedric Honnet, Jack Forman and Stefanie Mueller is available online.

Source: MIT