Some natural organisms, such as bone and coral reefs, have an incredible ability to adjust to varying amounts of stress, drawing on nearby minerals for structural reinforcements as the need arises. Scientists at Johns Hopkins University have succeeded in replicating this adaptive mineralization process in the lab, showing off a new type of material that alters its stiffness as more force is applied.

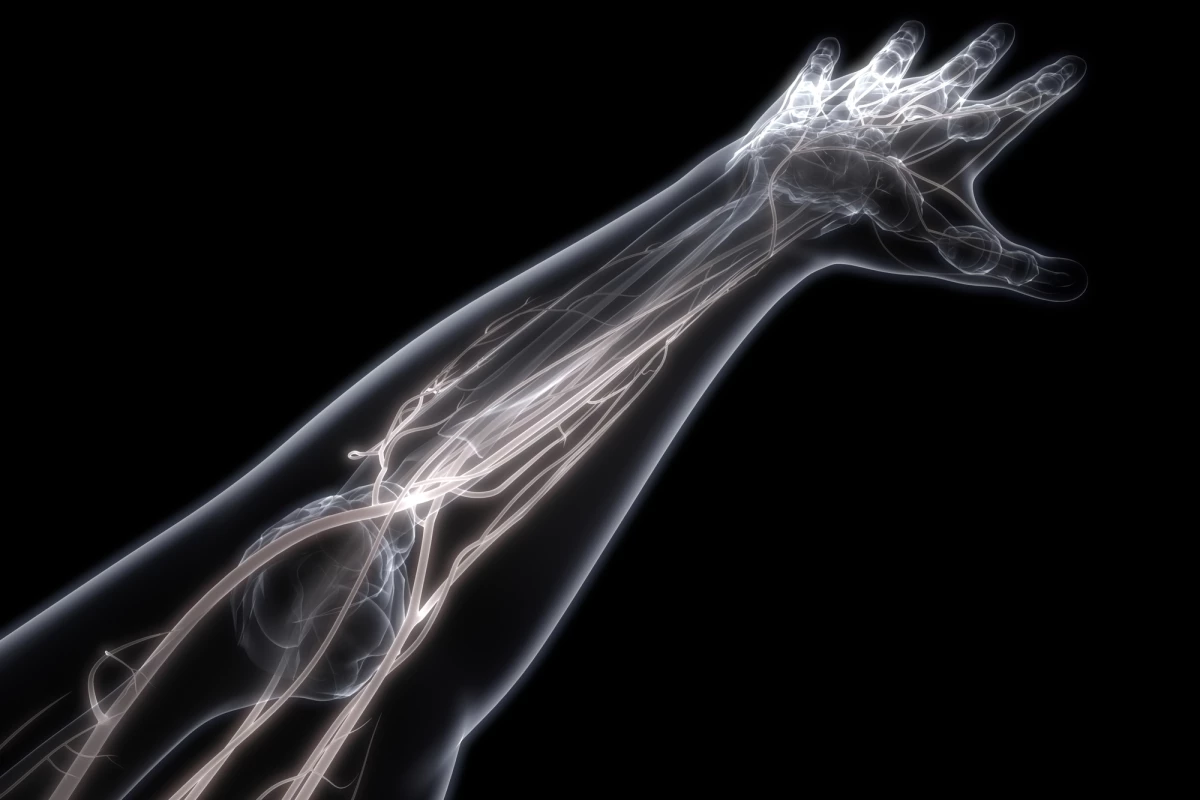

Human bone is one example of a natural material that is able to regulate its own structural makeup, adding minerals from the surrounding blood via cellular signaling. Coral reefs can work in similar ways, upping the mineralization in areas that may be subjected to the greatest ocean forces as a means of survival.

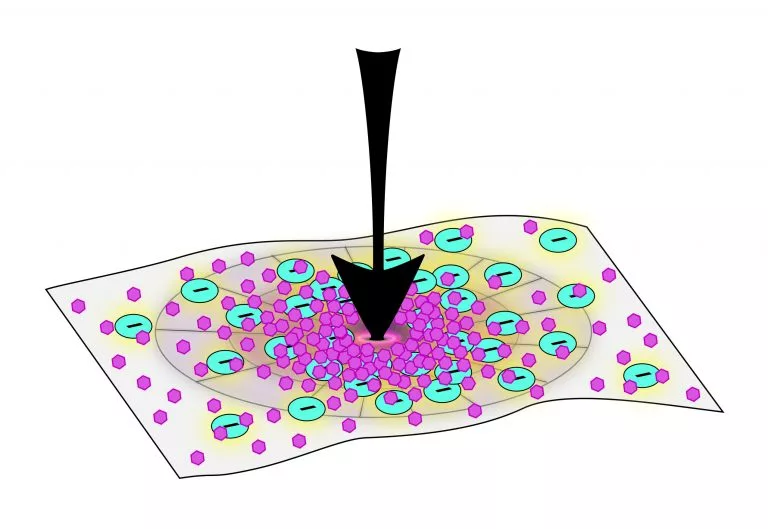

The Johns Hopkins researchers set out to develop a material that could work in a similar way, bringing in additional minerals as a response to extra stress. This began with polymer films that can translate mechanical forces into electrical charges, which are proportional to the amount of stress they endure.

These films were then placed in a fluid made to mimic ionic concentrations of blood plasma. The idea was that the varying electrical charges could act as signals, just like those used by bone to call in reinforcements, and cause minerals to form on the surface.

A beam designed to increase stress levels across the material’s surface was anchored to one end. The result was that parts of the material subjected to greater forces had more minerals accumulate on the surface, with the mineral height proportional to the stress applied.

“Our findings can pave the way for a new class of self-regenerating materials that can self-reinforce damaged areas,” says senior author of the study Sung Hoon Kang.

By altering the composition of the ion fluid, the researchers also found they could control the kind of minerals that formed on the material, possibly granting it even greater versatility. The team imagines all sorts of uses for a material of this kind, including acting as a scaffold to boost treatments for bone disease or resins for dental care.

“Imagine a bone implant or a bridge that can self-reinforce where a high force is applied without inspection and maintenance. It will allow safer implants and bridges with minimal complication, cost and downtime,” says Kang,

The research was published in the journal Advanced Materials.

Source: Johns Hopkins University