Producing leather from animal skin is a practice humans have engaged in for thousands of years, but the environmental consequences of modern processing techniques have led some to seek a greener alternative. Among them are scientists at Finland's VTT Technical Research Centre, who have been developing an alternative leather made from fungi and they've now demonstrated a way to produce continuous sheets of the stuff at commercial scales.

Conventional leather production has a heavy environmental burden, which begins with the land, water and energy associated with mass livestock farming. But processing the leather has an impact too, requiring large amounts of toxic chemicals. So-called "vegan leather," which is made from synthetic materials, avoids the issues around animal products, but also requires toxic chemicals to process and takes a long time to biodegrade. It therefore carries a lot of the same risks to the environment.

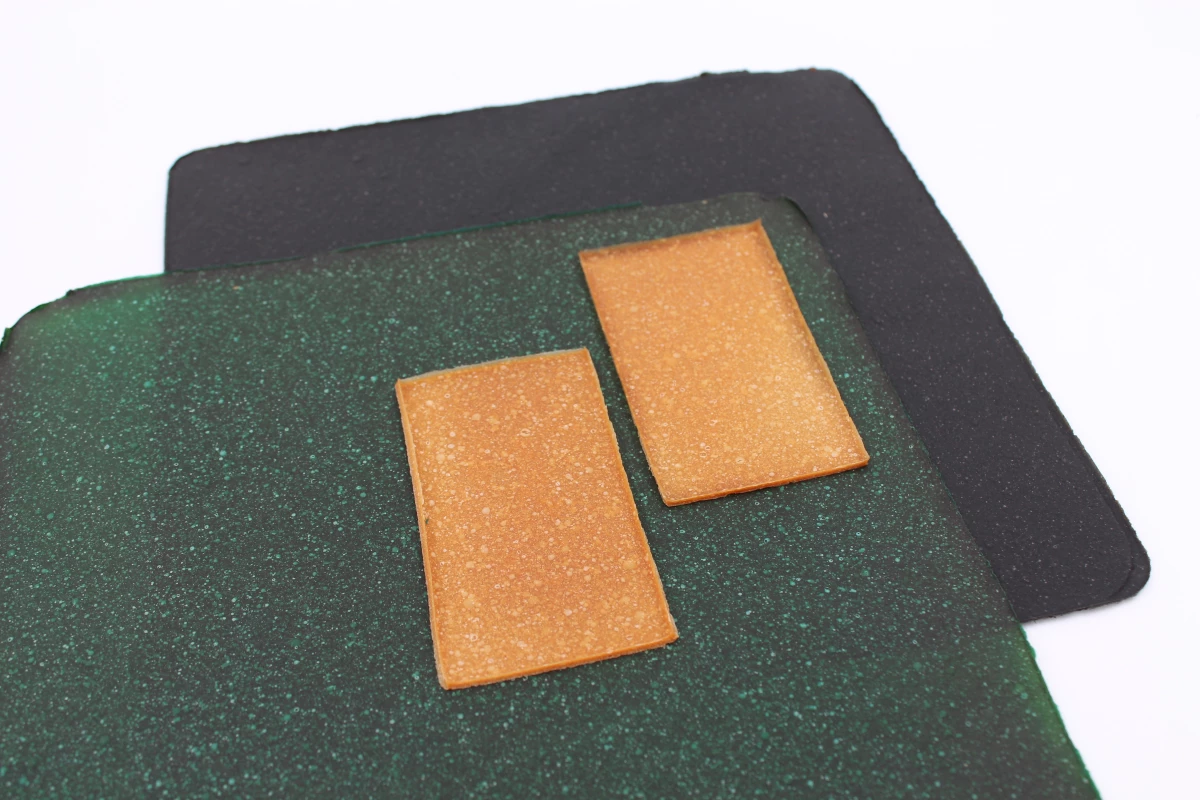

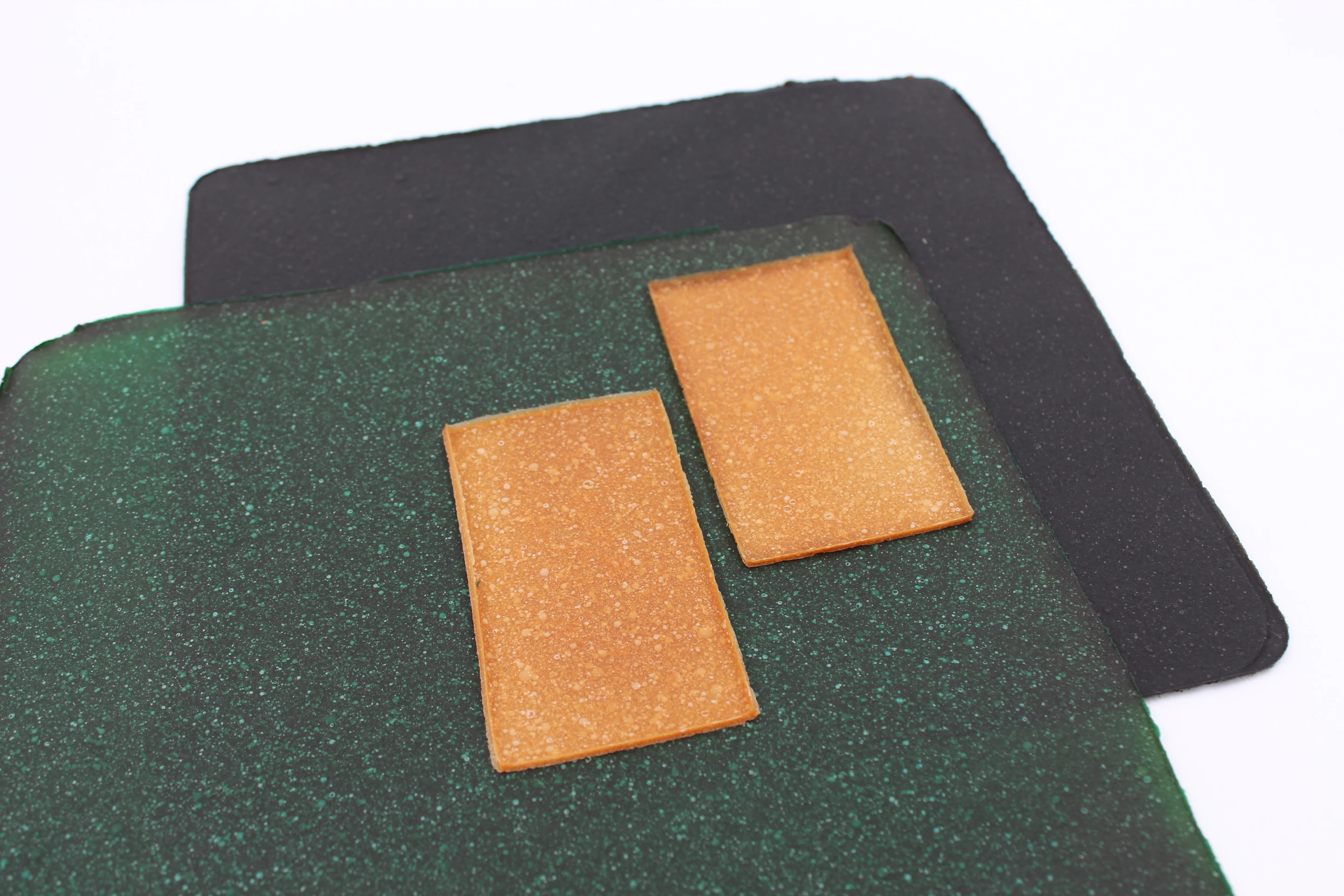

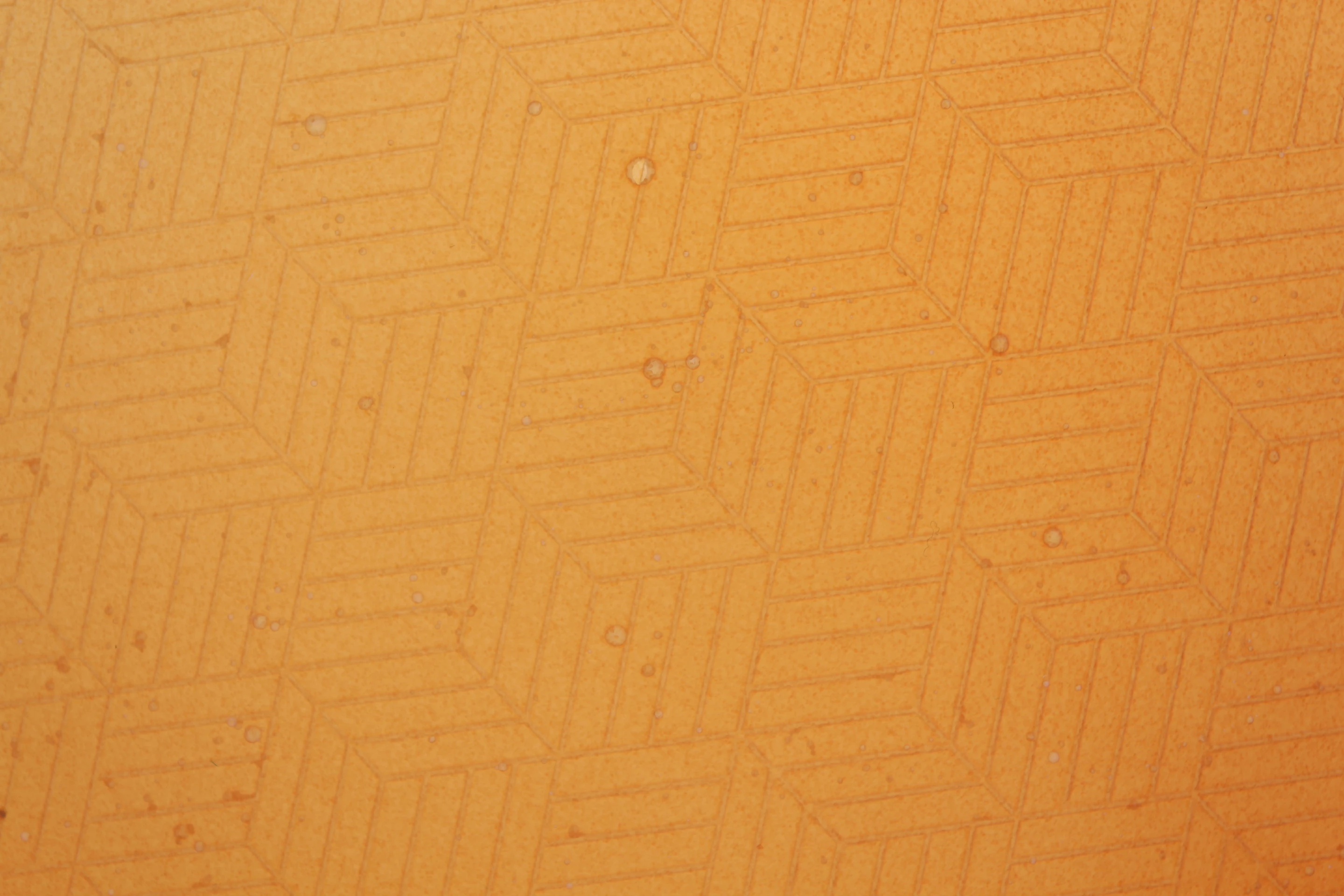

The VTT researchers have been cooking up an alternative they believe can sidestep these problems entirely. The approach starts with threaded webs of organic material known as mycelium, which sprawl out beneath the ground and support mushrooms as the grow. Using this biomass to produce textiles and fabrics is something that has been done for centuries, but through their experiments, the VTT team has refined these processes to produce a skin-like material with similar feel and strength to real leather.

“The material has a leathery look and feel and can be as strong as animal leather," says VTT Senior Scientist Géza Szilvay. "It also offers the possibility to be colored and patterned, and it does not contain any backing or supporting materials.”

The scientists first revealed their process back in 2019, but noted that a bottleneck remained when it came to scaling it up for industrial-style production. This stemmed from the limitations of mycelium cultivation, which could only take place in a planar, two-dimensional form. The researchers have now come up with a new patent-pending technology they say busts this bottleneck apart, relying on liquid fermentation in common bioreactors to scale things up to commercial levels.

This new technique allows the scientists to produce mycelium leather at scale, rolling out continuous sheets of the stuff at a rate of one meter (3.3 ft) per minute. The scientists say this can be adapted to industrial roll-to-roll production methods, and they are currently exploring applications such as footwear, accessories and garments.

The video below provides an overview of the research.

Source: VTT Technical Research Centre