Given roads are everywhere and involve some carbon-intensive processes to build, scientists are investigating how alternative materials could make the whole process more sustainable. We've seen how this could include everything from coffee grounds, to discarded face masks to building rubble, and now a team of researchers in Switzerland has opened up another interesting possibility, demonstrating how patterns of string carefully laid by robotic arms can be used to bind asphalt together in place of environmentally damaging bitumen, resulting in greener roads that are also easier to recycle after use.

The research was carried out at the Swiss Federal Laboratories for Materials Science and Technology (Empa) and actually stems from an interesting art and science project, in which pillars were made from a mix of gravel and string. Rather than using concrete to bind the loose stones together, the gravel was interlocked with a thread that held the whole structure in place. The resulting pillars reached heights of 80 cm (2.6 ft), and in pressure testing were capable of withstanding loads equal to 20 tonnes (22 tons).

This led the scientists involved to wonder if a similar technique could be applied to road construction, where asphalt, also made up of rocks in various sizes, is usually combined with a bitumen binding material to produce the finished product. Using string to reinforce the roads instead could offer a number of advantages over bitumen, which needs to be extracted from crude oil and generates air pollutants during production and use.

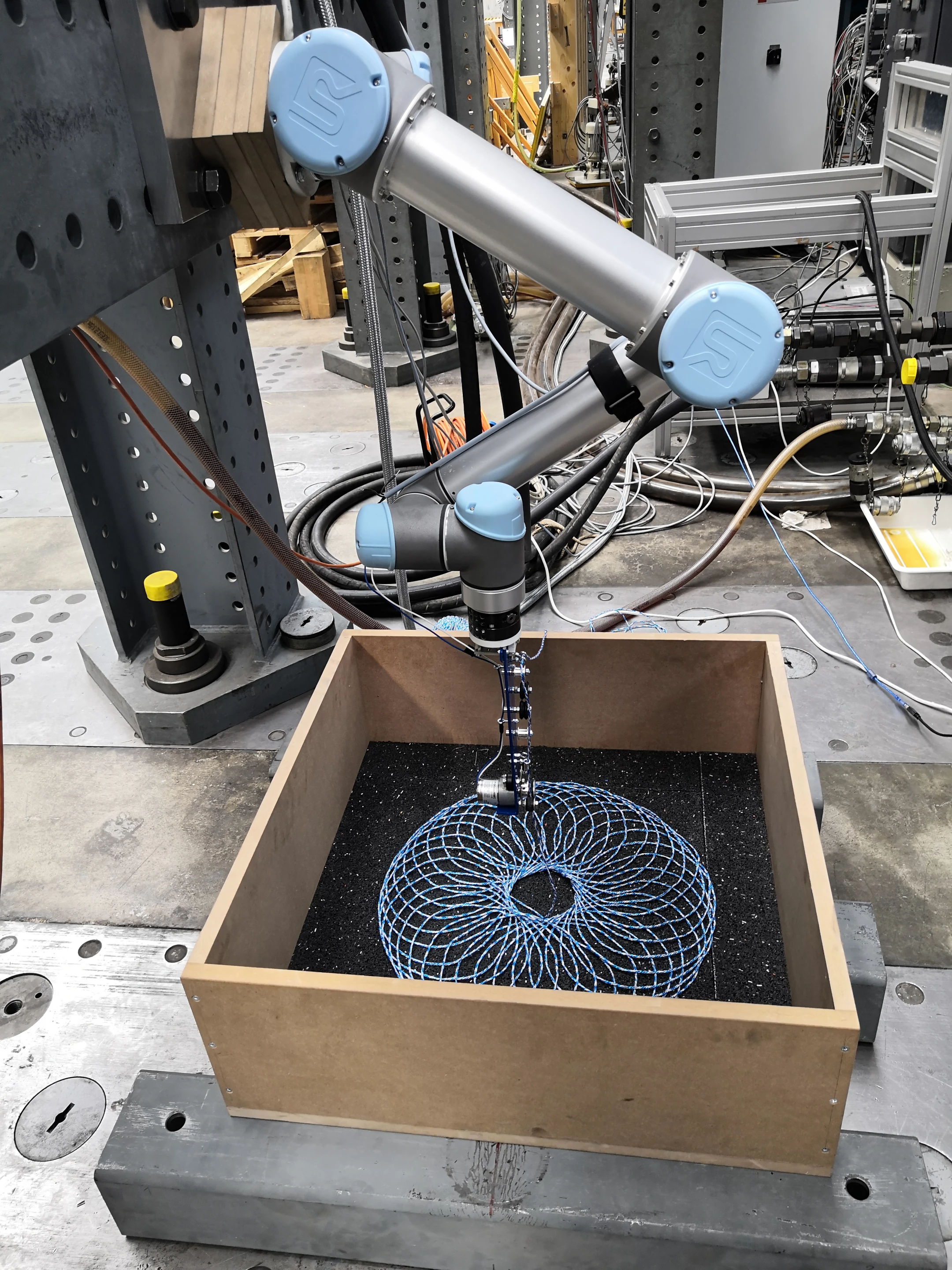

The experiments started with a rubber mat laid on the bottom of a test box to simulate the deformable bed beneath the pavement. Onto this layers of gravel and string were stacked on top of one another, with a robotic arm laying out the string in a pre-programmed pattern. The string featured is the same as that used by Swiss citizens to wrap up waste paper, in keeping with the sustainable theme of the research. This process was repeated until five layers of gravel and thread were formed inside a test box.

Load tests were then carried out which revealed that the subsurface road material made of gravel stones and thread was able to withstand pressures equal to half a tonne (0.55 ton) without displacing too many of the stones. These tests were complemented with computer modeling that helped the researchers track the movement of the stones and the tensile forces on the threads.

The team notes that the current form of the material is nowhere near ready for use in roads, but believe these early experiments demonstrate the potential of the approach. From here, the researchers plans to carry out dynamic load testing with rolling pressure to more closely simulate the real-world conditions of roads, and also test out how different patterns and mesh widths of the string could impact the material's stability.

"We want to find out how a recyclable pavement could be produced in the future," explains team member Dr. Martin Arraigada. "To do this, we are using digitalized construction methods in road construction for the first time."

The video below offers a look at the technology in action.

Source: Empa