There are few things better than lazing around the house on a warm summer day, whose fragrant zephyrs speak of spicy isles and heaven-breathing groves.* At least, until the neighbors start their leaf-blowers and the city needs to tear up the sidewalks. Noise pollution is one of the scourges of urban and suburban life, which can drown out nature's melodies to cause annoyance, stress, and hearing loss. Now, however, a team of South Korean engineers has invented a remarkable window that lets air in while keeping a great deal of noise out.

Simply put, noise is any sound one does not want to hear. Measured in decibels (a 10 dB increase in sound corresponds to a tenfold increase in sound pressure and energy, with 0 dB the human auditory threshold), a beautiful countryside with only natural sounds has a sound level in the range of 10 to 20 dB. In a bedroom having sound levels above 45 dB, most people will experience considerable difficulty in getting to sleep and staying asleep.

At a distance of 50 ft (15 m), those leaf-blowers mentioned earlier have sound levels in the 70 to 75 dB range, and the jackhammers tearing up the sidewalks outside check in at about 90 dB inside your house. Most of us respond by closing the windows and doors, feeling that putting up with a stuffy, closed-in feeling is better than enduring the noises of an urban or suburban setting.

Now an alternative is appearing. A clever use of acoustic metamaterials by Professor Sang-Hoon Kim of the Mokpo National Maritime University and Professor Seong-Hyun Lee of the Korea Institute of Machinery and Materials in South Korea will enable the design and construction of windows that allow air to pass through, but reduce environmental noise by about 35 dB, depending on the frequency of the external sound. This level of sound reduction is about five dB better than that of a standard vinyl double-pane window.

Metamaterials are composed of patterns of locally resonant structures. Kim and Lee have discovered how to build a sound-blocking metamaterial that has continuous paths to allow the passage of air by using Helmholtz resonators. If you have ever heard a jug band, or simply blown air across the top of a soda bottle to make a whistle, you know about Helmholtz resonators. More generally, they consist of a constrained volume of air that can be accessed from the outside by a neck or a small hole.

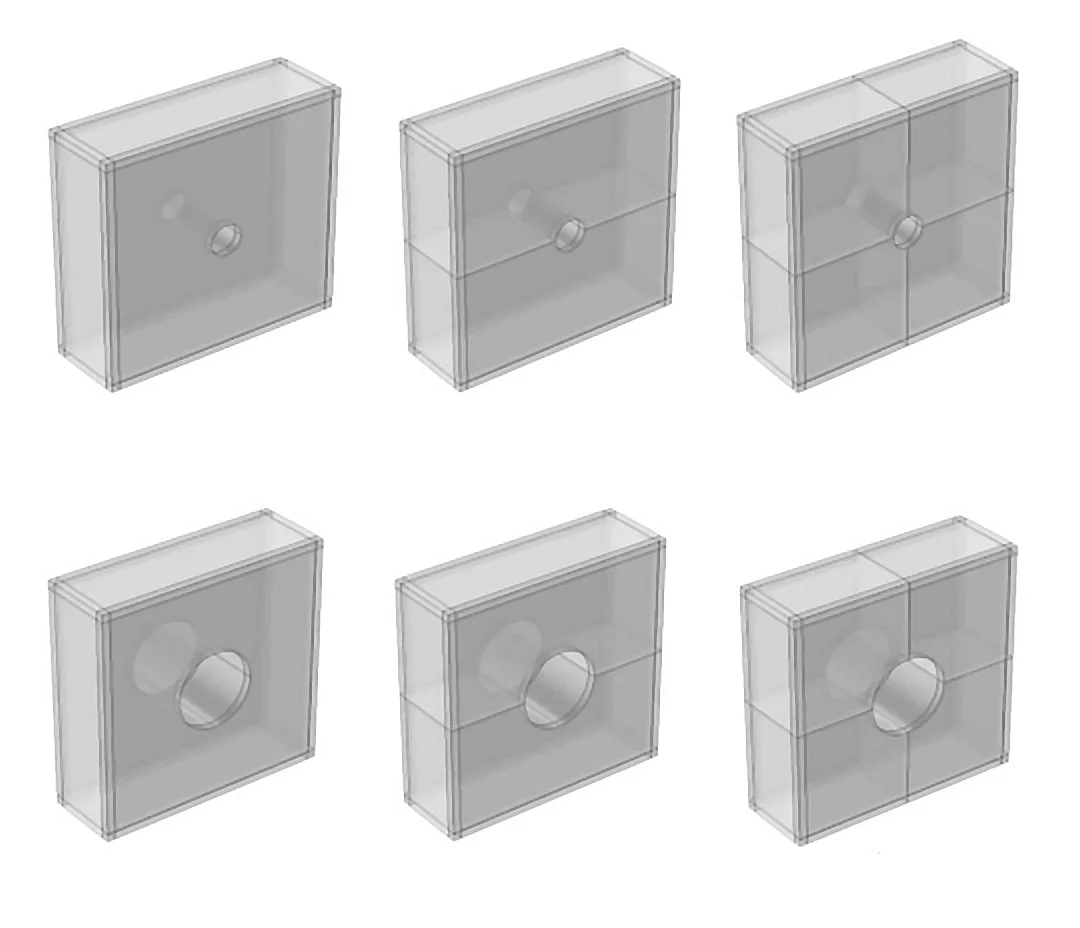

The particular resonators used for the silent window are called diffraction resonators. These are hollow boxes measuring 6 x 6 x 1.6 in (15 x 15 x 4 cm) that are made from acrylic that is 0.2 in (5 mm) thick. There are two sets of three diffraction resonator designs, one set having a central air hole 0.8 inches (2 cm) in diameter, and the other set with a 2-inch (5-cm) air hole. Each set has different internal dividers that break the inner air space into one, two, or four equal-sized volumes. The dividers serve to change the resonant frequencies so that a wider frequency band can be silenced. In all cases a cylindrical air filter is inserted through the air hole to prevent the usual Helmholtz resonator whistle.

Why do the diffraction resonators pass air but not sound? One part of the answer is that when sound passes through the air holes, the sound waves are strongly diffracted into the entire volume of the diffraction resonator, so that very little of the sound can pass directly through the air holes.

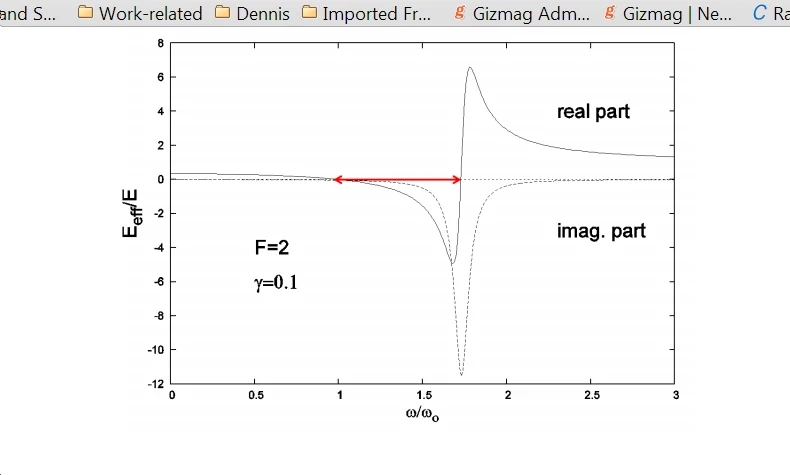

The other part of the answer is that the diffraction resonators cause the air to have negative compressibility over a fairly wide frequency band. Normal sound waves in air are made up of a series of compressed and expanded regions. The energy of the compressed air drives that material to expand, and vice versa. However, when compressibility is negative, compressed air is less dense than air at lower pressure. As a result, compressed air does not expand, which is the mechanism that normally allows sound waves to travel through materials. Instead, sound waves are strongly attenuated as they travel through a material with negative compressibility.

The combination of these two effects defines a frequency band within which sound passing through the window is strongly attenuated.

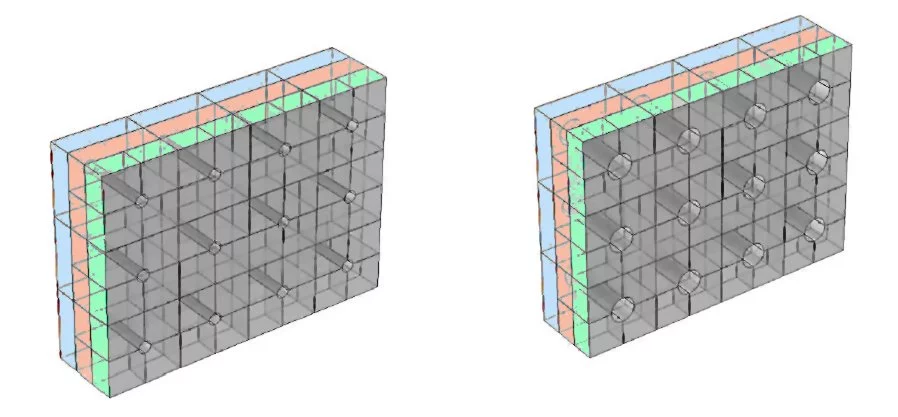

Prototype windows were made by combining the diffraction resonators in a triple-layer thickness, four resonators wide and three resonators high, measuring 24 x 18 x 5 in (61 x 46 x 13 cm) thick. One window was made of resonators with the 0.8-in air holes, and the other with 2-in air holes. As shown in the figure above, the layers had one, two or four resonance chambers per air hole to try to achieve sound attenuation over a broad range of frequencies.

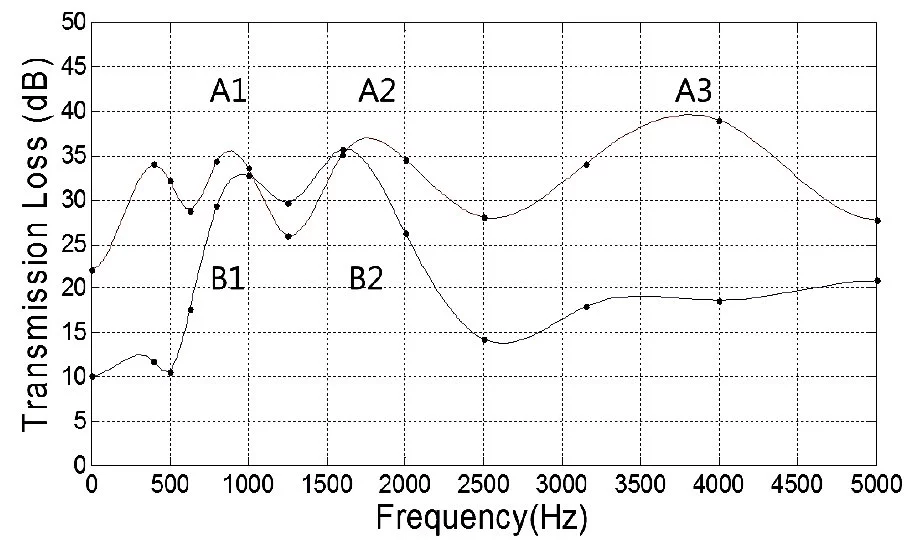

The test results showed that the window with the 0.8-in air holes reduced sound transmission by over 30 dB at frequencies from 200 to nearly 5,000 Hz, with over 20 dB attenuation even at very low frequencies. The window with 2-in air holes was intended as a compromise between sound attenuation and air passage. This window produced similar attenuation to that of the 0.8-in window for frequencies between about 700 and 2,000 Hz, with attenuation in excess of 15 dB for frequencies from 600 and 5,000 Hz.

The test windows are intended to represent proof of principle, as ultimate performance can be improved in many directions. Many of the overall properties can be improved by introducing more complex internal structures. The thickness of the window can be reduced by causing the air passing through the window to follow a curved path, which can also be used to obtain increased sound attenuation along with increased airflow. Additionally, the shape and size of the diffraction resonators are currently not optimal, and can be improved to give more favorable window size and performance.

The researchers have demonstrated the potential for their windows to change the urban/suburban living environment for the better. The silent windows have principles and structure simple enough that it need not be long before they hit the market – and my window frames.

* Apologies to Percy Shelley

Source: arXiv (PDF)