Scientists have developed what could be a much quicker and easier technique for astronauts to make building-construction bricks out of lunar soil. The secret lies in heating that moon dust, then sticking it in an aerospace-grade microwave oven.

If you were sending a crewed rocket to the Moon, the last thing you'd want to do is weigh that spacecraft down with big, bulky, heavy bags of cement. That said, if the astronauts were planning on living on the Moon for a while, they would need to build structures of some sort on its surface.

With that quandary in mind, a number of groups are exploring different methods that astronauts could use to convert regolith (lunar topsoil) into building materials. When it comes to producing bricks specifically, past efforts have involved utilizing equipment such as solar concentrators and high-powered lasers.

Another alternative is a process known as microwave sintering. In a nutshell, this involves exposing blocks of loose regolith to ultra-high-frequency microwaves. Naturally occurring metal particles within that regolith convert the microwaves to thermal energy (heat), causing them to fuse together. The result is a solid block of material.

Advantages of using microwave sintering to make moon-bricks include the facts that it is considerably faster and more energy-efficient than other proposed methods, plus it doesn't require any additives. Unfortunately, though, experiments conducted so far have produced bricks that were too structurally flawed to be of any practical use.

That's where the new variation on the technique comes in. It was developed by Dr. Hyu-Soung Shin and colleagues at the Korea Institute of Civil Engineering and Building Technology.

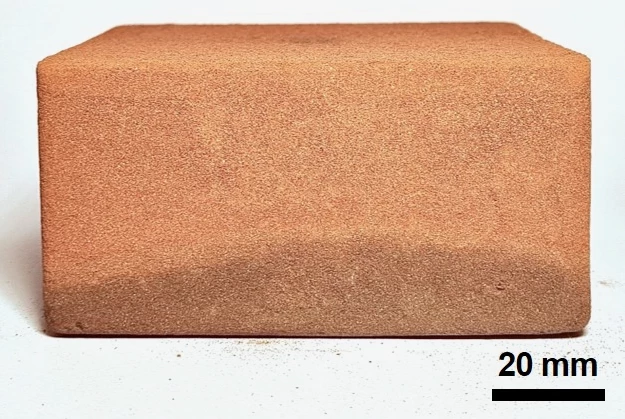

The scientists started by using conventional microwave sintering to produce solid bricks out of a commercial regolith simulant called KLS-1. Due to the fact that the heating process didn't occur uniformly throughout the material – as has been the case in previous studies – the bricks had internal cracks running along the boundaries between their localized hot and cold spots.

After some experimentation, it was found that this problem could be addressed by first heating the KLS-1 to 250 ºC (482 ºF) for about eight hours in a vacuum. The material was then placed in a multi-mode microwave sintering furnace, where it was held at an internal temperature of 1,080 °C (1,976 ºF) for 10 minutes. In a final step, the regolith was left to cool at room temperature for about 16 hours.

The resulting bricks had no cracks, plus core sampling showed that density, porosity and compressive strength was uniform throughout each one.

"The robust reproducibility and similarity in physical and mechanical properties validate the viability of microwave sintering in manufacturing large and uniform blocks suitable for application as construction materials on the Moon," the scientists state in a paper on their research. That paper was recently published in the Journal of Building Engineering.

Source: National Research Council of Science and Technology via EurekAlert