Researchers from South Korea have developed a thin, highly-flexible film that could enable a new generation of wearable devices that wrap around your finger or wrist. The multiferroic film even amplified the properties inherent in the bismuth ferrite it was made from, and the enhanced properties were preserved when the film was curved into a cylindrical shape.

Flexible electronics are not a new concept. As far back as 2005 Gizmag reported on integrated circuits printed on paper or fabric, and more recently the hype has been around flexible graphene-based displays.

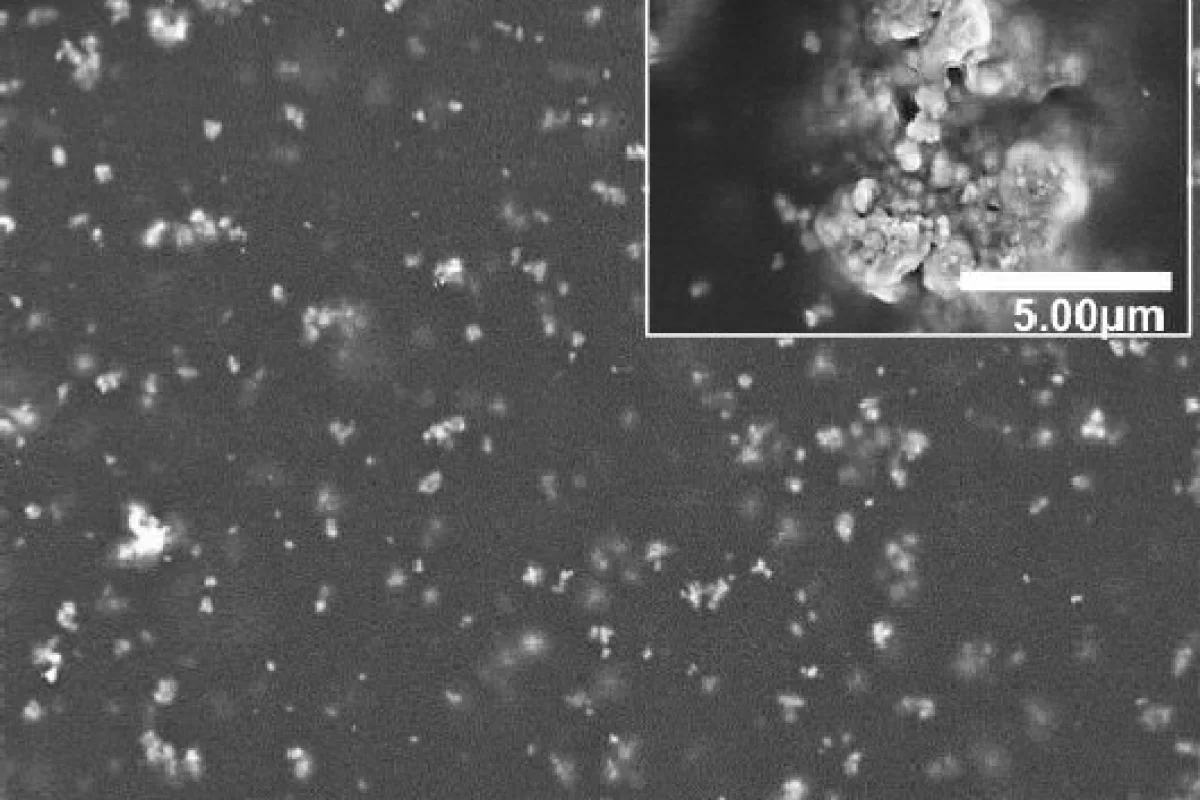

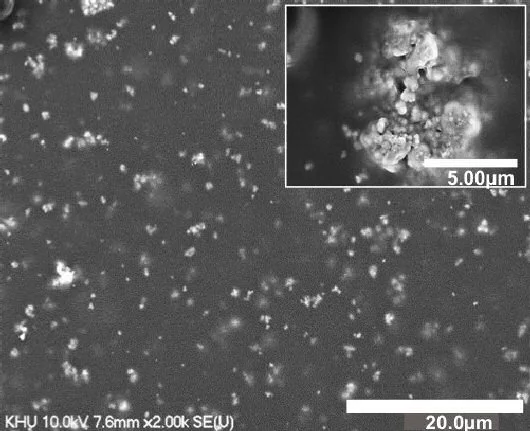

But the team of Koreans, led by Young-Pak Lee of Hanyang University, took a new approach. They added bismuth ferrite nanoparticles to a polyvinyl alcohol polymer solution and converted that into a film via a multi-step method called drop-casting. Once dried, the so-called multiferroic films could be bent or stretched with no loss of potency in the magnetic or electric properties of the bismuth ferrite.

Normally bismuth ferrite has serious issues with current leakage, Lee notes, because bismuth ions are volatile, and it also exhibits weak magnetization. But when synthesized down to nanoparticle size and mixed into the polymeric film, these problems all but disappeared. Better yet, the film exhibited much stronger dielectric properties than bulk bismuth ferrite.

The researchers expect flexible multiferroics to have applications in energy-efficient, instant-on wearable health monitoring equipment and virtual reality attire, as well as any other small electronics that could benefit from being bent around an object or body part. They're not quite ready for commercial use, though, and the team is now turning its energy toward both improving the film's multiferroic properties and exploring ways to make it even more flexible.

A paper describing the research was published in the journal Applied Physics Letters.

Source: AIP Publishing