As many a fancy-refrigerator-owner will know, fingerprints tend to be highly visible on stainless steel. A new transparent coating could help, however, as it goes about reducing the appearance of prints in three ways.

Actually a type of varnish, the "sol/gel nano-lacquer" is being developed by Germany's FEW Chemicals and assessed by a team at the Fraunhofer Institute for Microstructure of Materials and Systems.

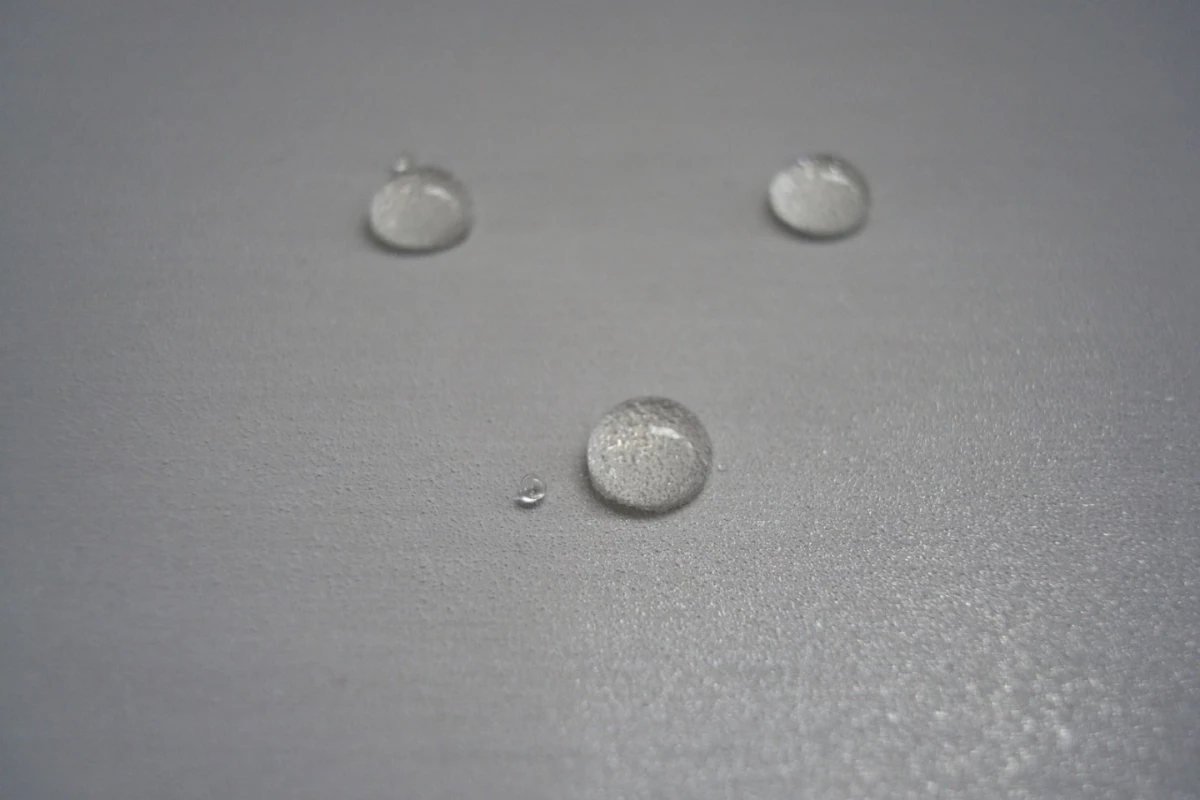

First of all, it's superhydrophobic and oleophobic. In other words, it's water- and oil-repellant, limiting how much finger-oil fat initially sticks to it.

Additionally, it contains tiny particles that give the coated steel surface a microscopically rougher texture, which consists of mini peaks and valleys. As a result, any fat that does stick only adheres to the peaks, not reaching the valleys below – so there's less contact area.

Finally, the refractive index of the varnish is the same as that of finger-oil fat. This means that regardless of whether light is hitting a clean part of the coated surface or one with fat on it, that light is reflected in the same manner, so the fingerprinted areas have the same appearance as the clean ones.

The Fraunhofer researchers are currently developing a testing system for various versions of the varnish, in which a fingertip-like stamp is dipped into a solution that's similar in composition to skin oil, and then pressed against coated steel samples. A combination of spectrometric and optical techniques are then used to automatically assess how much of that solution is left on those samples, and how visible it is.

It is hoped that the varnish will be ready to go into large-scale production by the end of 2020.

Source: Fraunhofer