Recently the public has become aware of the potential of light field photography through the introduction of the Lytro camera. Light field recording allows an enormous degree of post-processing, letting you create just the image you want to print and display. A print, however, expresses only one aspect, no matter how carefully chosen, of the recorded light field. Can light field information be somehow encoded into a print, so an object can be examined from this side and that, or with different lighting conditions? A team of researchers at the University of California at Santa Cruz, Hewlett-Packard Laboratories, and 3M have made the first steps toward a positive answer by developing reflectance paper.

The reflectance function of a point in a scene captures the appearance of that point as a function of lighting direction. Imagine looking at a door recessed in a frame. If incident light comes from a source on your right, some of the right edge of the door will be in the frame's shadow. Similarly, if the light comes from your left, the left edge of the door will be shaded. By capturing the angle-dependent reflectance function for every pixel representing the object, it is possible to create an image which shows the object's response to light hitting it from different directions. This is a type of light field photography, though it differs from that of Lytro photography in that it records an object in different angles of incident light, rather than light rays striking an image plane from different directions.

So what happens when you want to print a reflectance-encoded photograph? Unfortunately, a conventional print will only record one lighting condition for the door - if the right edge is shaded, the left is not. The UC approach makes it possible to print an image that responds to the direction of the light in the same manner as the original scene, so that the shadows and highlights move appropriately with changes in illumination.

James Davis, an associate professor of computer science in the Baskin School of Engineering at UC Santa Cruz, explained that ordinary printed photos look the same regardless of the angle of the light because flat paper can't reflect light the way three-dimensional objects do. The idea for reflectance paper came from discussions in a graduate course Prof. Davis was teaching.

"If the paper is flat, it [the image] will always look flat no matter what you print on it. So the question became how to get the surface of the paper to have geometry to it," Davis said. "With the reflectance paper, for each pixel we have a little dimple that has all angular directions on its surface. Now we can print ink over it in a way that controls the angles of light that will be reflected from each pixel."

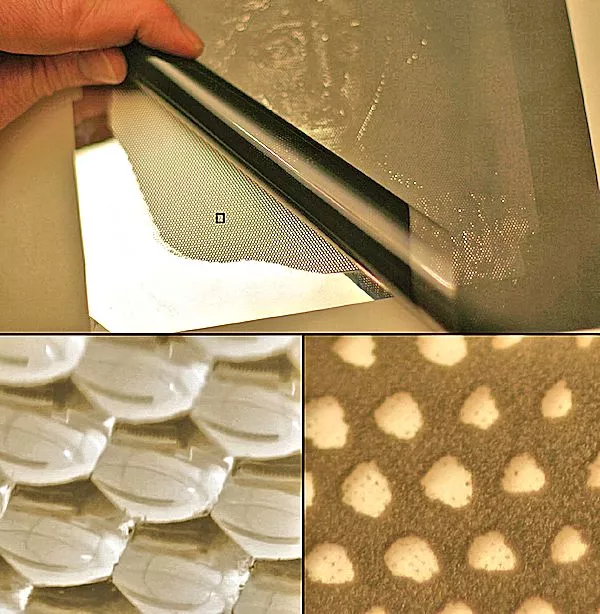

A pattern of millimeter-size spherical dimples are impressed into the paper in a hexagonal lattice pattern. The depth of the impression (resulting from pressing the paper on a commercial plastic microlens array) is about 50 microns, so that the dimple represents 70% of a hemisphere - sufficient for encoding lighting information from any angle. The dimples are then given a mirrored surface using silver or aluminum sputtering.

To avoid problems with the specular reflection from existing inks, the encoded light field information describing different lighting directions is printed onto a mask which is transparent over the dimples. In the present demonstration a 32x32 matrix of light field information is printed over the dimples - roughly the largest matrix which can be printed using ink-jet printers.

"Right now the quality of our prints is nowhere near what museums would need, but the basic idea of being able to capture all of that information in a print is absolutely of interest to them," says Davis. "It's not just a novelty. There are potential uses where people would want to take a picture and examine it later from different lighting angles."

Recently, the ability to very finely print colors has emerged, so that a resolution of 100,000 pixels per inch is possible. This would allow the use of dimples about a hundred times smaller while allowing the encoding of more light field information on the mask. The result would be more detailed than the best black and white photographic prints, as well as being enhanced by inclusion of chosen varieties of light field information. The short video below is extremely helpful in understanding this new process of photo printing.

Source: University of California-Santa Cruz