Although many aspects of the automobile manufacturing process are now automated, the inspection of welds is still typically performed by humans. A new robotic system, being developed in Germany, should make the checking of those welds easier and more accurate than ever before.

Currently, individual automobile components have to be manually loaded onto a rotating apparatus, so they can be turned around and viewed from all angles. Even then, workers will often adopt awkward poses in order to see the welds, possibly leading to repetitive strain injuries.

Additionally, the amount of time allocated to both loading and then checking each part is limited, potentially causing workers to rush their inspections. What's more, because different workers may view the same welds from different angles, there's a lack of consistency in the process.

It was with these limitations in mind that the German government's EASY COHMO (Ergonomics Assistance Systems for Contactless Human-Machine Operation) project was initiated. Led by the Fraunhofer Institute for Telecommunications, the multi-group collaborative effort is tasked with developing a system in which a robotic arm will automatically pick components off the assembly line, then hold them up in front of a human inspector.

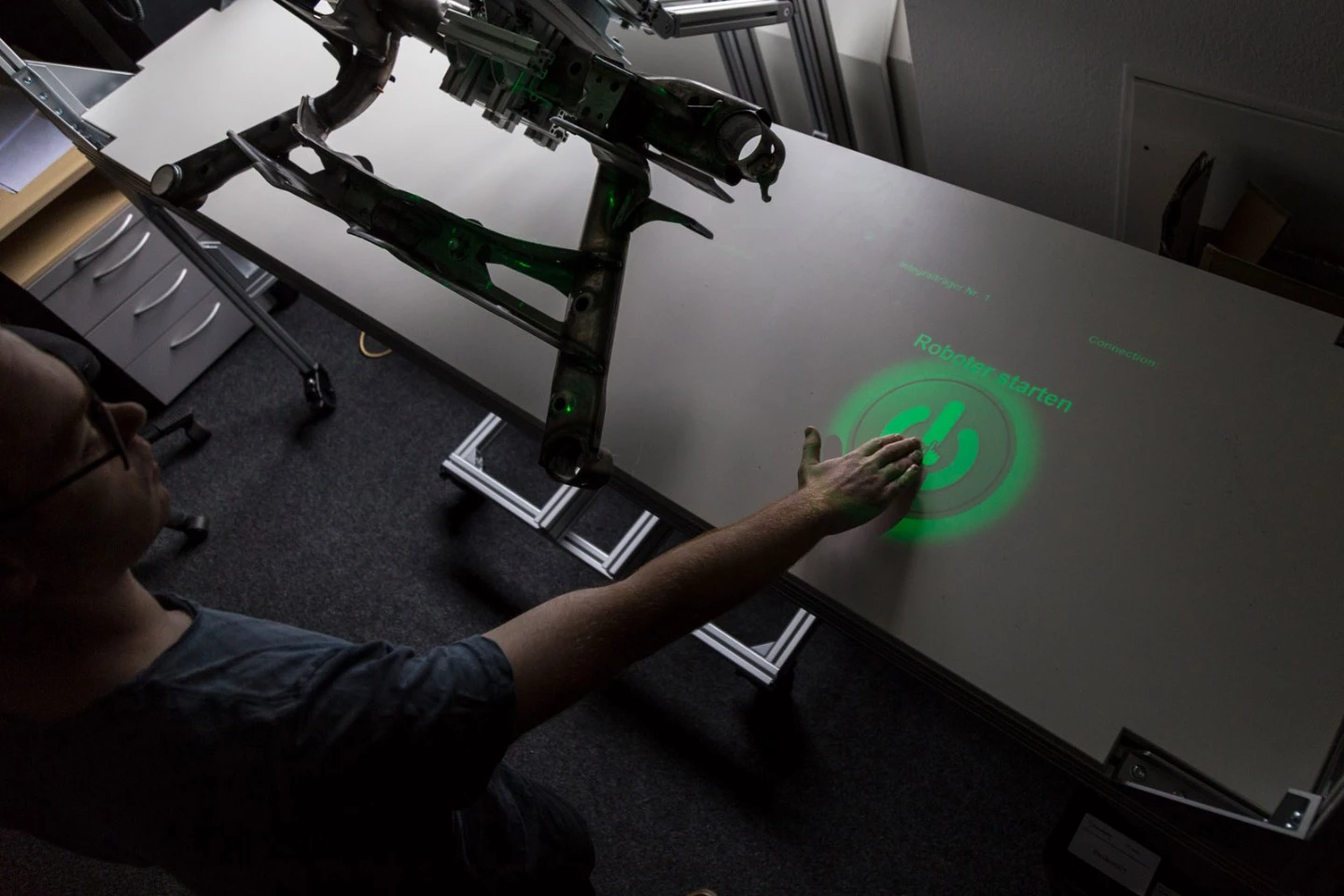

Utilizing voice commands, along with a gesture-recognition interface that's projected onto both the workbench and the part itself, that person will instruct the arm to position the component in exactly the right position for inspection of its welds. If there are any problems with the welds, those can likewise be logged via either gestures or voice, with their locations being recorded utilizing a finger-tracking system.

It is hoped that the setup will ultimately reduce worker injuries while also improving efficiency and reducing the amount of defects that are missed. Plans call for the technology to initially be integrated into the production facilities of project partner Volkswagen.

Source: Fraunhofer